Production process of high-extensibility plastic packaging film

A technology with high extensibility and production process, applied in the field of packaging film, it can solve the problems of unguaranteed mechanical properties, uncontrollable degradation and high cost of the film, to enhance mechanical properties and chemical stability, improve anti-ultraviolet aging ability, and improve resistance to aging. The effect of thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare the modifier:

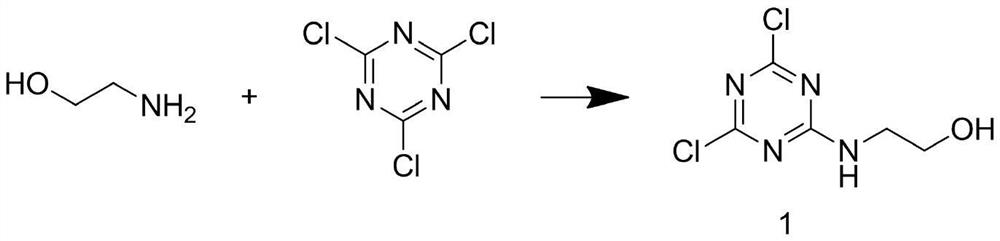

[0036] Step S21, mix cyanuric chloride and acetone, then add ethanolamine solution dropwise at a temperature of 0°C, control the dropping rate to 1 drop / second, keep the temperature constant after the dropping, continue stirring for 2 hours, and finish stirring Afterwards, aqueous sodium hydroxide solution was added dropwise, and post-treatment was carried out. The process of post-treatment was as follows: the obtained reaction solution was suction-filtered and washed to obtain intermediate 1;

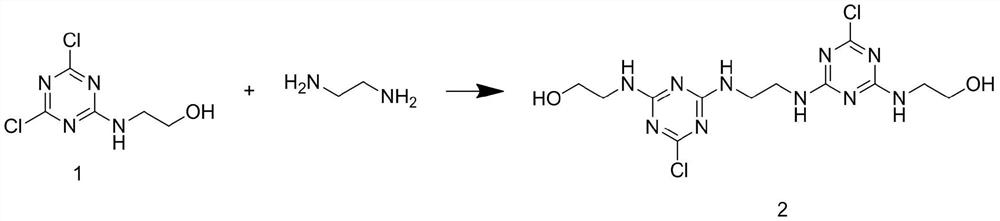

[0037] Step S22, at a temperature of 50°C, add a mixed reagent to the intermediate 1, react at this temperature for 4 hours, and perform post-treatment after the reaction. The post-treatment process is: suction filter and wash the obtained reaction solution After obtaining intermediate 2;

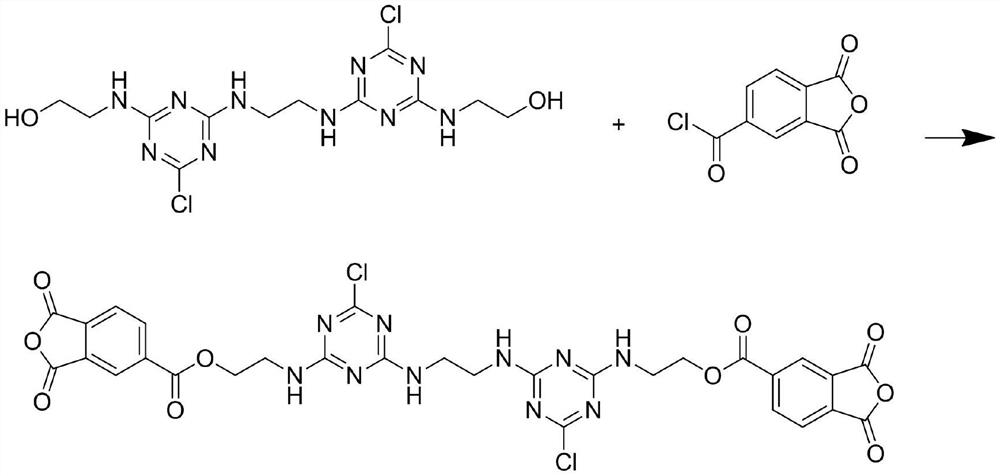

[0038] Step S23, mixing chlorinated trimellitic anhydride and pyridine, when a white precipitate is produced, adding intermediate 2 and tetrahydrofuran, stirring and ...

Embodiment 2

[0041] Prepare the modifier:

[0042] Step S21, mix cyanuric chloride and acetone, then add ethanolamine solution dropwise at a temperature of 10°C, control the dropping rate to 2 drops / second, keep the temperature constant after the dropping, continue stirring for 3 hours, and finish stirring Afterwards, aqueous sodium hydroxide solution was added dropwise, and post-treatment was carried out. The process of post-treatment was as follows: the obtained reaction solution was suction-filtered and washed to obtain intermediate 1;

[0043] Step S22, at a temperature of 50°C, add a mixed reagent to the intermediate 1, react at this temperature for 4 hours, and perform post-treatment after the reaction. The post-treatment process is: suction filter and wash the obtained reaction solution After obtaining intermediate 2;

[0044]Step S23, mixing chlorinated trimellitic anhydride and pyridine, when a white precipitate is produced, adding intermediate 2 and tetrahydrofuran, stirring and...

Embodiment 3

[0047] Preparation of auxiliary components:

[0048] Step S31, mixing phenol, phosphorus oxychloride and anhydrous magnesium chloride, then reacting at 75°C for 2h, then raising the temperature to 100°C, and reacting for 20h, after the reaction, stop heating and cool to room temperature to obtain solution a;

[0049] Step S32, at a temperature of 8°C, mix methanol and triethylamine, then dropwise add solution a, after the dropwise addition, raise the temperature to 50°C, react for 10 hours, and after the reaction, lower the temperature to room temperature, Carry out post-processing, the process of post-processing is: extracting with deionized water and ethyl acetate, drying the organic phase with anhydrous magnesium sulfate, concentrating under reduced pressure after drying, removing the solvent to obtain auxiliary components.

[0050] Wherein, the mass ratio of phenol, phosphorus oxychloride and anhydrous magnesium chloride in step S31 is 9.4:7.21:0.1; the mass ratio of metha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com