Novel environment-friendly ash removing agent for aluminum alloy and preparation method thereof

An aluminum alloy, a new type of technology, applied in the field of aluminum alloy new environmental protection deashing agent and its preparation, can solve the problems of blood, nerve, reproductive system harm, difficult wastewater treatment, benzene substances, etc., to achieve low sewage treatment cost, Good effect of protecting health and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

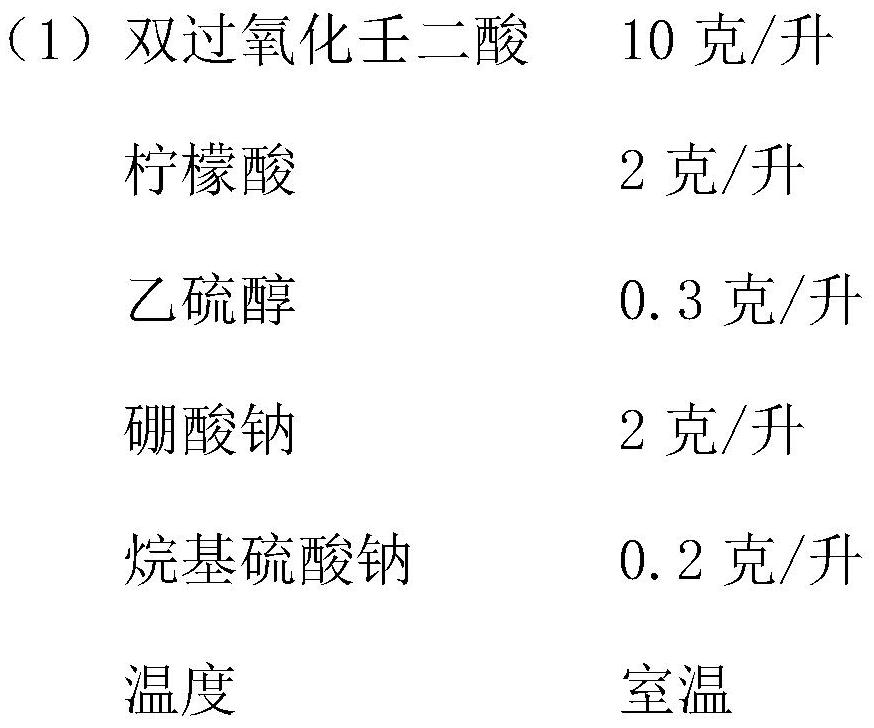

[0026]

[0027] (2) Production method: first add half of the required water, the conductivity of the water is not more than 100μS / m, then add diperoxide azelaic acid and stir for 8-10 minutes at a stirring speed of 80-100 rpm, After adding citric acid, ethanethiol, sodium borate and sodium alkyl sulfate, the stirring time is 10-20 minutes, and the stirring speed is 80-100 rpm.

Embodiment 2

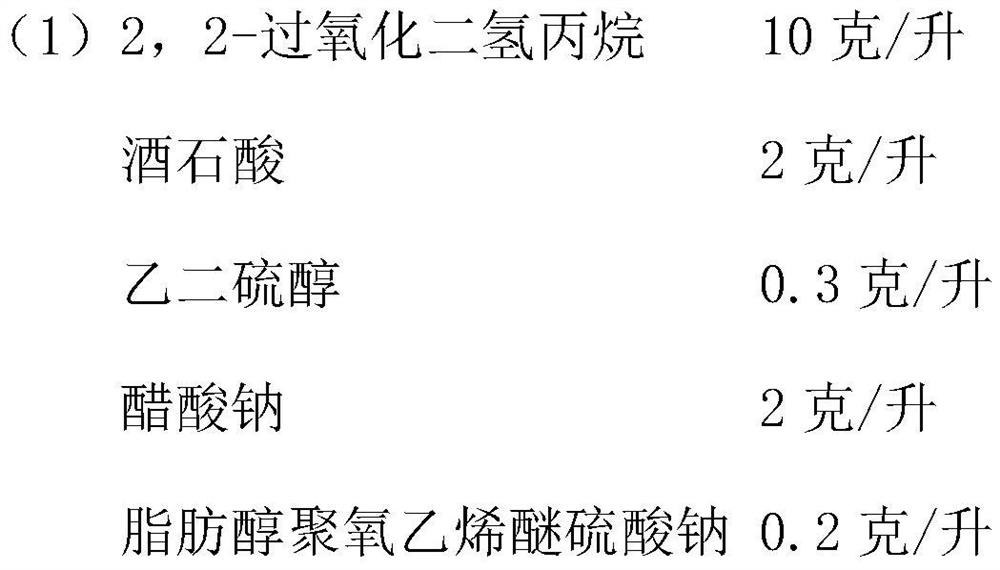

[0029]

[0030]

[0031] (2) Production method: first add half of the required water, the conductivity of the water is not more than 100μS / m, then add diperoxide azelaic acid and stir for 8-10 minutes at a stirring speed of 80-100 rpm, After adding 2,2-dihydropropane peroxide, tartaric acid, ethanedithiol, sodium acetate, and fatty alcohol polyoxyethylene ether sodium sulfate, the stirring time is 10-20 minutes, and the stirring speed is 80-100 rpm.

Embodiment 3

[0033]

[0034] (2) Production method: first add half of the required water, the conductivity of the water is not more than 100μS / m, then add diperoxide azelaic acid and stir for 8-10 minutes at a stirring speed of 80-100 rpm, After adding 2,2-bis-(4,4-di-tert-butylperoxycyclohexyl)propane, malic acid, 1-propanethiol, sodium sulfate, glycerin fatty acid ester sodium sulfate, the stirring time is 10-20 minutes , the stirring speed is 80-100 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com