Method for plating surface of copper nanowire with carbon

A technology of copper nanowire and carbon plating, which is applied in the field of carbon plating on the surface of copper nanowire, multiple integrated carbon plating technology and the preparation of CuNWs/C anti-corrosion coating, which can solve the problem of electronic conductivity, weak mechanical strength, step To achieve the effect of improving performance and service life, high mechanical strength and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

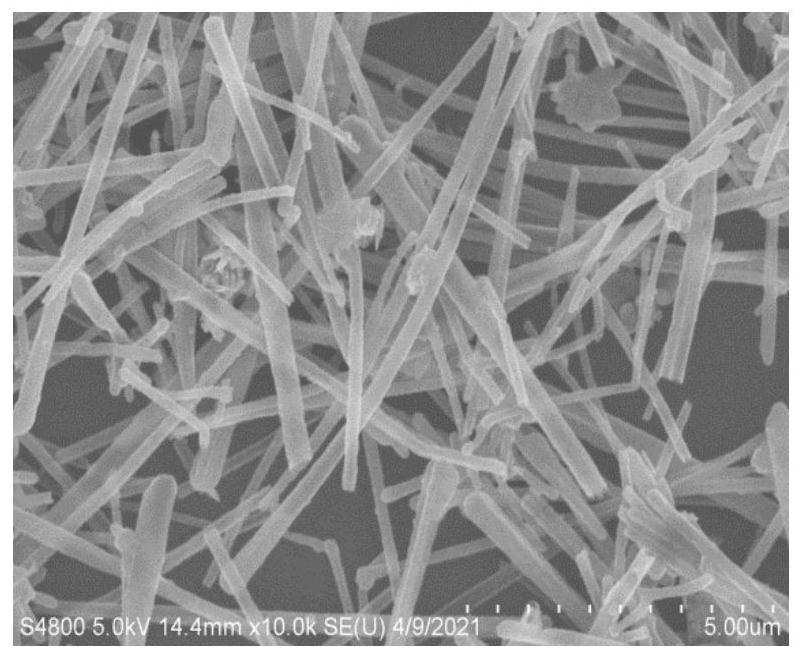

[0028] The preparation method of the copper nanowire thin film of the present embodiment comprises the following steps:

[0029] S1. Weigh 0.964g Cu(NO 3 ) 2 ·3H 2 Add O to 40 mL of ultrapure water, draw 8 mL of ethylenediamine with a needle, and add it to the above Cu(NO 3 ) 2 ·3H 2 In the aqueous solution of O, mix evenly, the solution is dark blue, which is recorded as solution A; weigh 480g NaOH and dissolve it in 800 mL ultrapure water, and place the beaker in an ice-water bath to obtain solution B; add the mixed solution A to the cooling In solution B, stir evenly (about 10min), the solution is uniform and clear dark blue, which is recorded as mixed solution C; pipette 800 μL hydrazine hydrate with a pipette gun, add to the above mixed solution C, and stir until the solution turns light blue (about 10 min), which is recorded as solution D; put solution D in a water bath at 75 °C and let it stand for 1 h to obtain crude CuNWs; filter the obtained crude CuNWs with ult...

Embodiment 2

[0031] The multiple integrated carbon coating device of this embodiment includes the following accessories:

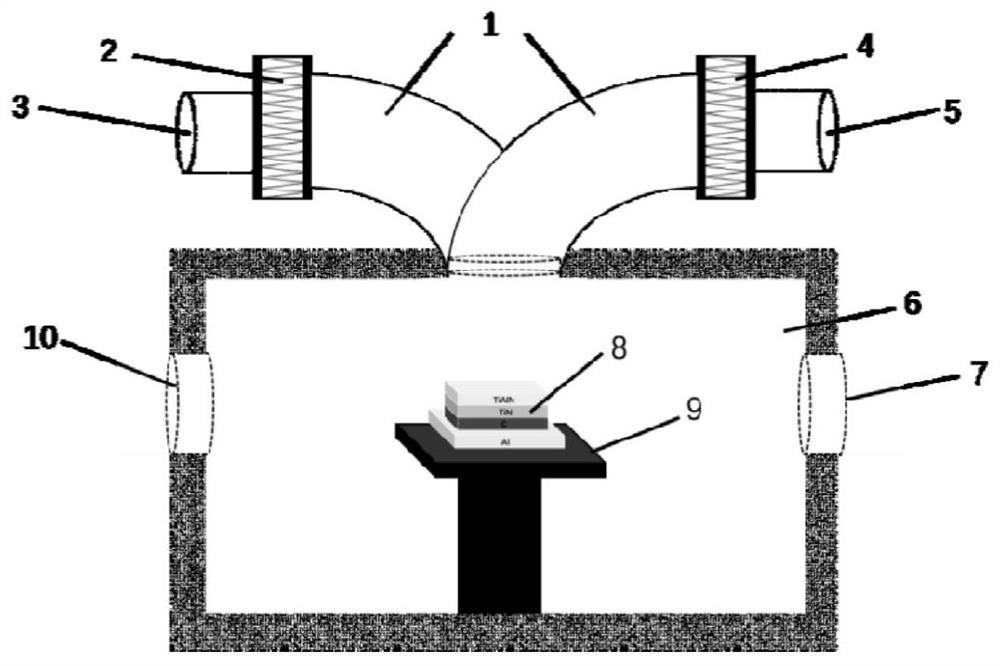

[0032] S2. A multi-component integrated carbon coating device, which is a multi-component device integrating magnetic filtration, arc discharge and plasma.

[0033] Such as figure 1 As shown, the device consists of a magnetic filter elbow 1, a first arc discharge source 2, a second arc discharge source 4, a first solid target 3, a second solid target 5, a chemical vapor reaction chamber 6, and an air inlet 7 , a deposition base 8 , a rotatable base 9 , and an air outlet 10 . figure 1 The shown magnetic filtering and screening arc discharge plasma device includes two or more magnetic filtering bent pipes and one magnetic filtering main line pipe, and can be equipped with more than two arc sources for operation. A deposition substrate 8 is also provided in the chemical vapor reaction chamber 6 , that is, the film deposition chamber. The deposition base 8 is placed on ...

Embodiment 3

[0035] A method for preparing a CuNWs / C anti-corrosion coating in this embodiment comprises the following steps:

[0036] S3. After cleaning the deposition substrate 8, fix it on the rotatable base 9 in the thin film deposition chamber; vacuumize the two arc discharge sources, the two magnetic filter elbows 1 and the thin film deposition chamber, and the vacuum degree reaches 1 ×10 -4 Pa; use plasma to clean the coating surface of the deposition substrate 8 to remove oil and impurities on the coating surface of the deposition substrate 8;

[0037] S4. Introduce the arc discharge carbon source into the magnetic filter elbow 1 for screening, the deposition arc current is 100~120A, the magnetic filter elbow current is 1.6~2.5A, the negative bias voltage is 160~320V, and the deposition time is 10min ;

[0038]S5. Turn off the arc discharge power supply and the magnetic filter power supply, release the vacuum degree, and open the film deposition chamber after returning to the nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com