Preparation method of multi-layer thin film passivation contact structure and full-passivation contact crystalline silicon solar cell

A contact structure, multi-layer thin film technology, applied in the field of solar cells, can solve the problems of narrow annealing process window and small band gap of polysilicon film, and achieve the effect of widening the annealing process window, large energy band bending, and enhancing passivation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

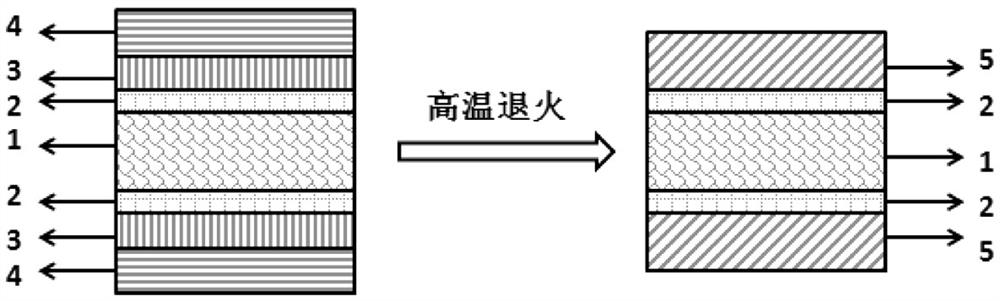

[0028] Such as figure 1 As shown, the present embodiment provides a P-type double-sided multilayer film passivation contact structure, and its structure before annealing is: Boron Doped nc-SiOx:H / Intrinsic nc-SiOx:H / SiOx / c-Si ( P) / SiOx / Intrinsic nc-SiOx:H / Boron Doped nc-SiOx:H; after annealing, its structure is: P + poly-SiOx / SiOx / c-Si (P) / SiOx / P + poly-SiOx. A P-type Czochralski monocrystalline silicon wafer is used as a crystalline silicon substrate 1 with a thickness of 200 μm and a resistivity of 1-10 Ωcm, and the surface of the crystalline silicon substrate is chemically polished on both sides. Its preparation process is as follows:

[0029] (1) Chemical cleaning of the crystalline silicon substrate 1 .

[0030] (2) Submerge the crystalline silicon substrate 1 in hot nitric acid solution at 100°C for 20 minutes, the mass fraction of the nitric acid solution is 68%, and grow a layer of oxidation on the front and back surfaces of the crystalline silicon subs...

Embodiment 2

[0035] Such as figure 1 As shown, the present embodiment provides a kind of N-type double-sided multilayer film passivation contact structure, and its structure is before annealing treatment: Phosphor Doped nc-SiOx:H / Intrinsic nc-SiOx:H / SiOx / c-Si (N ) / SiOx / Intrinsic nc-SiOx:H / Phosphor Doped nc-SiOx:H; after annealing, its structure is: N + poly-SiOx / SiOx / c-Si (N) / SiOx / N + poly-SiOx. An N-type Czochralski monocrystalline silicon wafer is used as a crystalline silicon substrate 1 with a thickness of 200 μm and a resistivity of 1-10 Ωcm, and the surface of the crystalline silicon substrate is chemically polished on both sides. Its preparation process is:

[0036] (1) Chemical cleaning of the crystalline silicon substrate 1 .

[0037] (2) Submerge the crystalline silicon substrate 1 in a hot nitric acid solution at 100°C for 25 minutes. The mass fraction of the nitric acid solution is 68%. A layer of oxidation is grown on the front and back surfaces of the crysta...

Embodiment 3

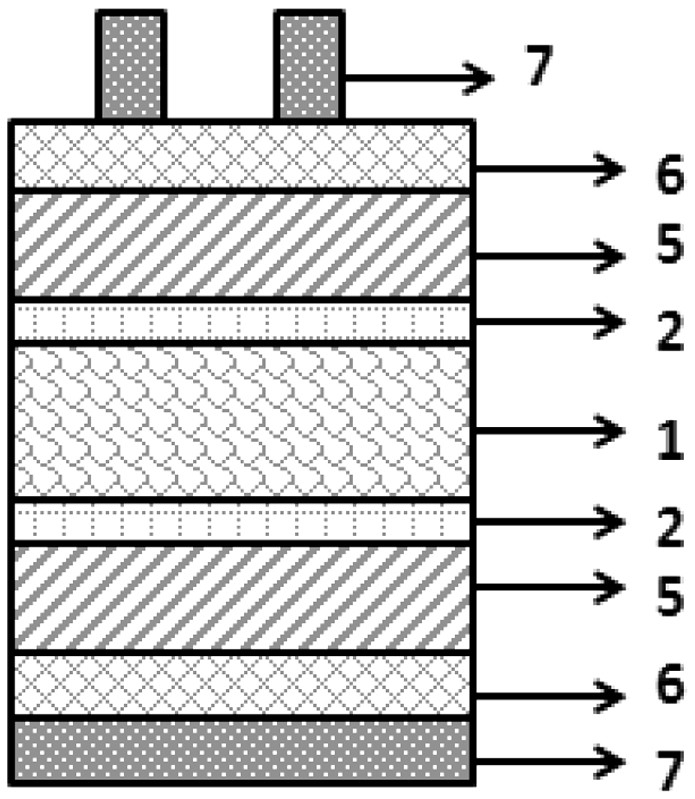

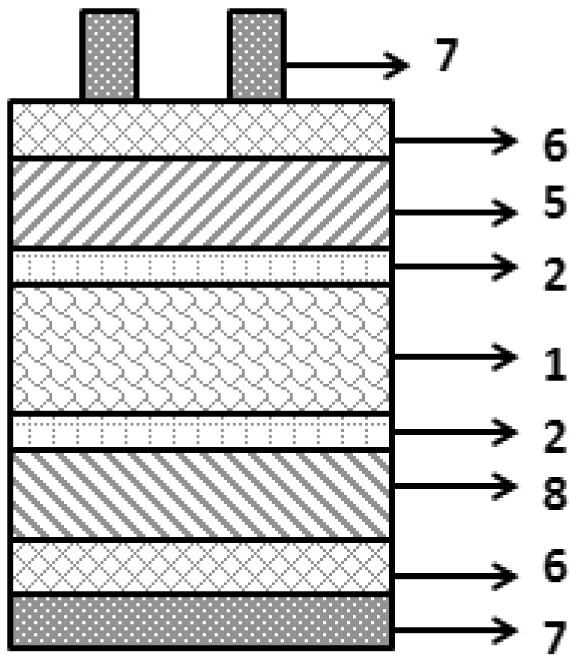

[0042] Such as figure 2 As shown, this embodiment provides a P-type double-sided multi-layer film fully passivated contact crystalline silicon solar cell. The battery structure is metal electrode / transparent conductive layer / N + poly-SiOx / SiOx / c-Si (P) / SiOx / P + poly-SiOx / transparent conductive layer / metal electrode. A P-type Czochralski single-crystal silicon wafer is used as a crystalline silicon substrate 1 with a thickness of 200 μm and a resistivity of 1-10 Ωcm, and the surface of the crystalline silicon substrate is chemically polished on both sides. Its preparation process is:

[0043] (1) Chemical cleaning of the crystalline silicon substrate 1 .

[0044] (2) Immerse the crystalline silicon substrate 1 in a hot nitric acid solution at 100°C for 28 minutes, the mass fraction of the nitric acid solution is 68%, and grow a layer on the front and back surfaces of the crystalline silicon substrate 1 by wet chemical oxidation method The silicon oxide lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com