Battery foil rolling additive and preparation method and application thereof

A technology of additives and extreme pressure additives, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of increasing production cost and delivery cycle, hindering rolling oil filtration, increasing recovery costs, etc., to achieve good dispersion performance and Filtration efficiency, reducing the cost of corona process, and improving the effect of surface dyne value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0063] 1,5-dihydroxy-3-adamantanecarboxylic acid, the preparation method is as follows:

[0064] Add 8g of adamantanecarboxylic acid and benzyltriethylammonium chloride (TEBAC, 0.7g) into a 150mL three-necked flask, stir in 80mL of 5% aqueous sodium hydroxide solution and 8mL of tert-butanol mixed solution and control the temperature at about 45°C . Add 8g of potassium permanganate and raise the temperature to 70°C and stir the reaction for 5h. Add 4g of anhydrous sodium sulfite to quench the reaction, stir and filter. The black filter cake was washed 5 times with 40°C hot water to obtain a clear filtrate. The clarified filtrate was adjusted to pH 3 with concentrated hydrochloric acid while stirring, and filtered after stirring for 20 min to obtain a white solid. The filtrate was extracted with ethyl acetate (40 mL×3 times), the combined organic layers were washed with saturated aqueous sodium chloride, dried over anhydrous sodium sulfate, and the solvent was evaporated to ...

Synthetic example 2

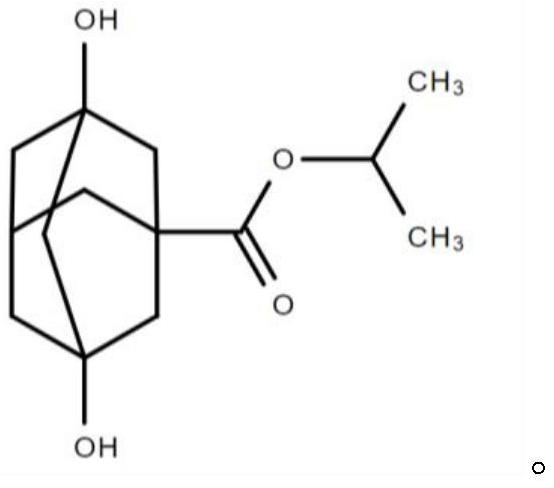

[0067] 1,5-dihydroxyl-3-adamantane carboxylate isopropyl ester, its preparation method comprises the steps:

[0068] (1) Place the dried 1,5-dihydroxy-3-adamantanecarboxylic acid (8g) in a 50mL round-bottomed flask, and slowly add a mixture of 5mL of oxalyl chloride and 8mL of dichloromethane dropwise with a constant pressure dropping funnel. After reacting at room temperature for 3 hours, the unreacted oxalyl chloride and solvent were removed by rotary evaporation to obtain 1,5-dihydroxy-3-adamantanecarbonyl chloride;

[0069] (2) Mix the 1,5-dihydroxy-3-adamantanecarbonyl chloride obtained in step (1) with 10 mL of dichloromethane to form a solution, and add dropwise a mixture of isopropanol and pyridine (isopropanol 3mL, pyridine 3mL), reacted in ice bath for 8h after the dropwise addition; the reaction solution was filtered to remove the pyridinium salt, washed, dried and concentrated to obtain 7.5g of isopropyl 1,5-dihydroxy-3-adamantanecarboxylate, The yield was 93.8%. ...

Embodiment 1

[0072] A battery foil rolling additive, comprising: 10% isobutyl laurate, 9.25% isobutyl myristate, 15% C12-14 fatty alcohol, 5% adamantane, 1,5 -23% of dihydroxy-3-adamantanecarboxylate, 37% of isopropyl 1,5-dihydroxy-3-adamantanecarboxylate, 0.75% of phosphorus-containing extreme pressure additive (phosphoric acid amine ester, Shandong Leon T304).

[0073]The preparation method of the battery foil rolling additive is as follows: uniformly mix isobutyl laurate, isobutyl myristate and C12-14 fatty alcohol according to the formula amount, and then, under the condition of heating and stirring at 60°C, adamantine Dissolve alkane, 1,5-dihydroxy-3-adamantanecarboxylic acid and isopropyl 1,5-dihydroxy-3-adamantanecarboxylate in it, stir evenly, add phosphorus-containing extreme pressure additives, stir for 1 hour until clear and transparent, and obtain The battery foil rolling additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com