Method for producing selenium-rich quick-acting fertilizer by using dioscorea zingiberensis wastewater

A quick-acting fertilizer and wastewater technology, applied to fertilizers made from biological waste, application, nitrogen fertilizers, etc., can solve the problems of serious pollution, COD content below 100 mg/L, backward production technology, etc., and achieve simple operation and protection Safe water quality and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

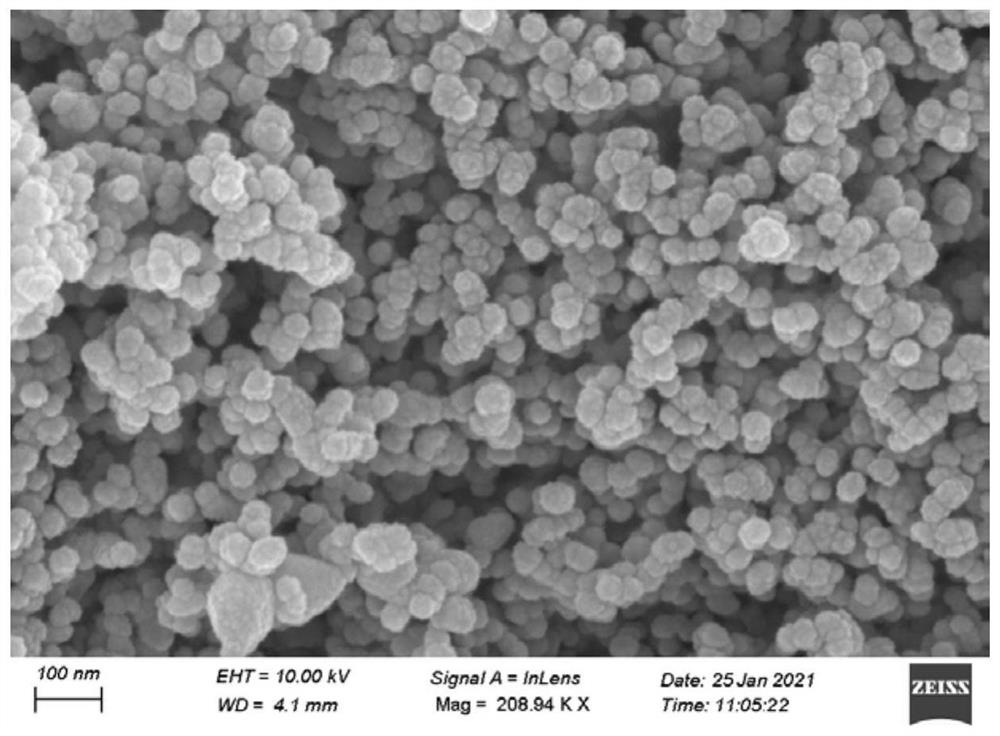

Image

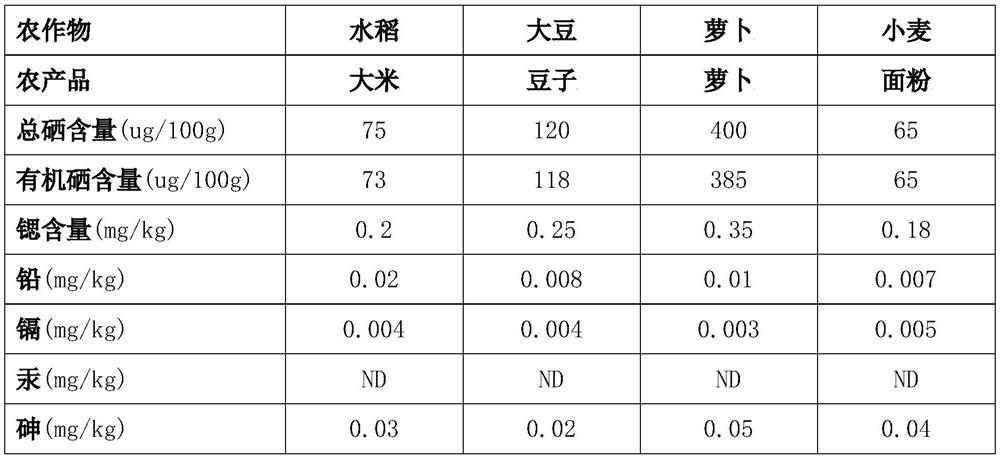

Examples

Embodiment 1

[0026] Embodiment 1 A kind of method utilizing yellow ginger waste water to produce selenium-enriched quick-acting fertilizer, its steps are as follows:

[0027] The first step: turmeric acid hydrolysis: add 50 kg of industrial hydrochloric acid and a certain volume of tap water to 1 ton of fresh turmeric, until pH = 1.0, the reaction temperature is 150 ° C, the pressure is 5 atmospheres, and the time is 2 hours. After the reaction is completed, filter to obtain turmeric 0.8 tons of waste water, about 0.1 tons of dry filter residue, which is used to extract diosgenin;

[0028] The second step: add 0.2 tons of phosphate rock powder and 0.1 tons of selenium-enriched wild rapeseed whole herb dry powder to the 0.8 tons of turmeric wastewater obtained in the first step, and react under high temperature and high pressure for 2 hours at a temperature of 150°C and a pressure of 5 atmospheres. After the reaction is completed Filter to obtain 0.6 tons of filtrate;

[0029] The third st...

Embodiment 2

[0040] Embodiment 2 A kind of method utilizing yellow ginger waste water to produce selenium-enriched quick-acting fertilizer, its steps are as follows:

[0041] The first step: turmeric acid hydrolysis: add 200 kg of industrial phosphoric acid and a certain volume of tap water to 1 ton of fresh turmeric, until pH = 1.2, the reaction temperature is 150 ° C, the pressure is 5 atmospheres, and the time is 2 hours. After the reaction is completed, filter to obtain 0.8 Ton of turmeric wastewater, about 0.1 ton of dry filter residue, used to extract diosgenin;

[0042] Second step: add 0.1 ton of selenium-enriched wild rape whole herb dry powder to 0.8 tons of turmeric waste water of first step gained, high temperature and high pressure reaction 2 hours, temperature 150 ℃, pressure 5 atmospheres, filter after completion of the reaction to obtain 0.75 tons of filtrate;

[0043] The third step: in the 0.75 tons of filtrate obtained in the second step, add potassium hydroxide, potassi...

Embodiment 3

[0049] Embodiment 3 A kind of method utilizing yellow ginger waste water to produce selenium-enriched quick-acting fertilizer, its steps are as follows:

[0050] The first step: turmeric acid hydrolysis: add 50 kg of industrial sulfuric acid and a certain volume of tap water to 1 ton of fresh turmeric, until pH = 1.0, the reaction temperature is 150 ° C, the pressure is 5 atmospheres, and the time is 2 hours. After the reaction is completed, filter to obtain 0.8 Ton of turmeric wastewater, about 0.1 ton of dry filter residue, used to extract diosgenin;

[0051] The second step: add 0.2 tons of phosphate rock powder and 0.1 tons of selenium-enriched wild rapeseed whole herb dry powder to the 0.8 tons of turmeric wastewater obtained in the first step, and react under high temperature and high pressure for 2 hours at a temperature of 150°C and a pressure of 5 atmospheres. After the reaction is completed Filter to obtain 0.7 tons of filtrate;

[0052] The third step: in the 0.7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com