Fluorine-containing photoacid generator as well as preparation method and application thereof

A technology of photoacid generators and solvents, which is applied in the preparation of sulfonates, photosensitive materials for optomechanical equipment, organic chemistry, etc., can solve the problems of incompatibility, sensitivity and resolution reduction, and reduce the Effects of phase separation, low absorption, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

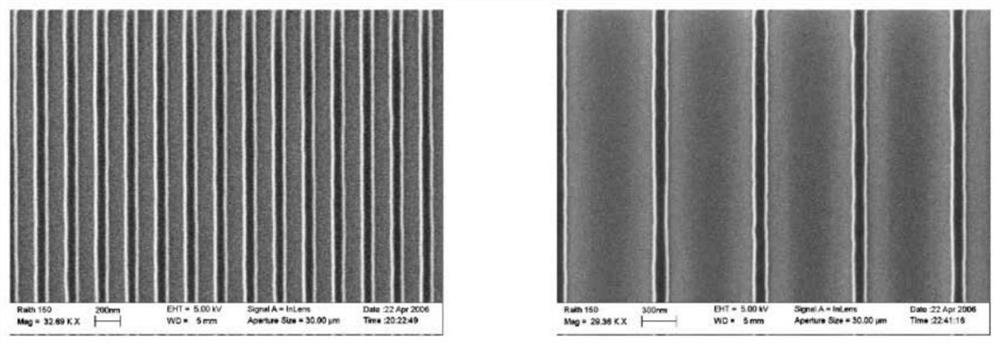

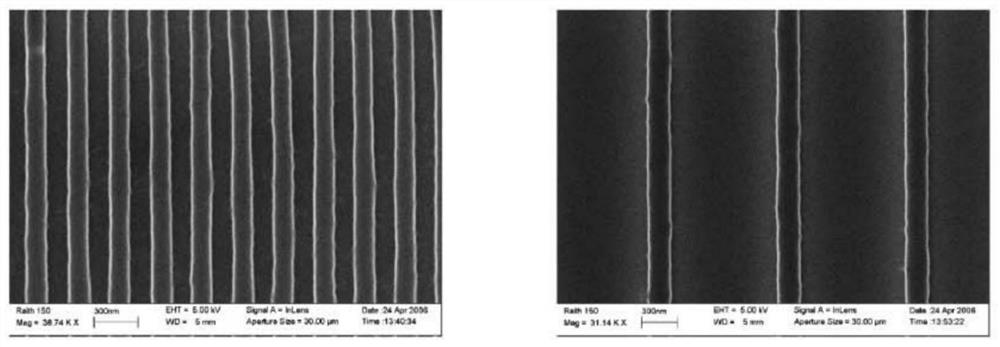

Image

Examples

Embodiment 1

[0035] The preparation process of fluorine-containing photoacid generator is shown below, and r.t in the figure represents room temperature;

[0036]

[0037] Concrete preparation method comprises the following steps:

[0038] 2,3,5,6-Tetrafluorophenol (10.1 g, 61.4 mmol) was added to 22 mL of oleum (containing 30 wt % SO 3 ) at room temperature for 18 hours, and then the mixture was poured into 200 mL ice-brine. The product was precipitated by stirring in NaCl solution until no more precipitate formed.

[0039] The mixture was filtered through a sintered glass disc, and the collected solid was placed in 330 mL of boiling CH 3 In CN, hot filtration through paper followed by slow cooling to ambient temperature gave a colorless crystalline product, 9.64 g (64%) after drying in vacuo. Then react overnight with methacrylic acid in trifluoroacetic acid (TFA) and trifluoroacetic anhydride (TFAA) under nitrogen as a medium, then react the reaction product with triphenylsulfur c...

Embodiment 2

[0041] The preparation process of fluorine-containing photoacid generator is as follows:

[0042]

[0043] Concrete preparation method comprises the following steps:

[0044] Trifluoromethylphenol (15g) was added dropwise to 20mL oleum (containing 20wt% SO 3), the mixture was maintained at 100 °C for 1 h. The mixture was stirred with water (25 mL) at room temperature for 2 days, then washed with a large amount of water (100 mL) and sodium chloride. A tan solid (19.1 g) was collected by filtration.

[0045] The intermediate was then reacted with methacrylic acid in trifluoroacetic acid (TFA) and trifluoroacetic anhydride (TFAA) overnight under nitrogen atmosphere. After removing the solvent and washing with ether, the yield was 51%. Finally, it was reacted with an aqueous solution of triphenylsulfur chloride (0.03 mol) with a mass fraction of 50 wt%, overnight at room temperature. The product was purified with dichloromethane and n-hexane to obtain triphenylmethacryloxy...

Embodiment 3

[0047] The photosensitive resin was prepared by using the fluorine-containing photoacid generator in Example 1, and the preparation process is as follows.

[0048]

[0049] Specifically include the following steps:

[0050] The composition ratio of the photosensitive resin in this embodiment is shown in Table 1, wherein the volume ratio of tetrahydrofuran and acetonitrile is 1:1.

[0051] Table 1 is the component ratio of photosensitive resin in the present embodiment

[0052] components Proportion(%) 2-Ethyl-2-adamantyl methacrylate 42 2-Oxotetrahydrofuran-3-yl methacrylate 8 2-thiophene methyl methacrylate 8 4-Hydroxystyrene 7 Fluorinated Photoacid Generators 3 Azodiethylbutyronitrile 1.5 THF, Acetonitrile 30.5

[0053] Weigh and weigh 4-hydroxystyrene, 2-oxotetrahydrofuran-3-yl methacrylate, 2-thiophene methyl methacrylate, and 2-ethyl-2-adamantyl methacrylate according to the proportion of ingredients , fluorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com