Copper-titanium corrosive liquid for integrated circuit and production process of copper-titanium corrosive liquid

An integrated circuit and etching solution technology, applied in the field of microelectronic chemical reagents, can solve problems such as unfavorable process production, operating environment pollution, environmental pollution, etc., and achieve the effects of increasing etching rate, increasing oxidation rate, and reducing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The sorbent is made by the following steps:

[0044] Step 1. Add 2.5mL of n-pentanol, 5.6mL of tetraethyl orthosilicate and 30mL of n-hexane into a three-necked flask, stir for 5min, then add 3.1g of cetyltrimethylammonium bromide, 0.6g of urea and 30mL of distilled water , after magnetically stirring for 40 minutes, transfer the reaction product to a polytetrafluoroethylene reactor, and place it in an oven at 120°C for 4 hours. Centrifuge at a speed of 15min for 15min, and dry the obtained precipitate in an oven at 60°C for 12h, and finally bake it in a muffle furnace at 550°C for 6h to obtain a mesoporous carrier;

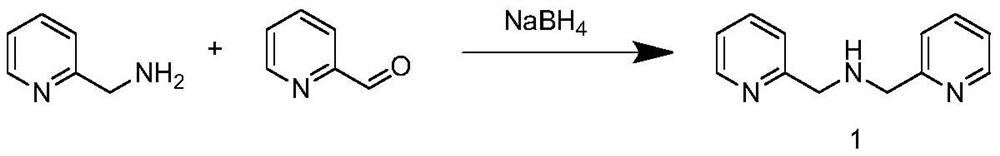

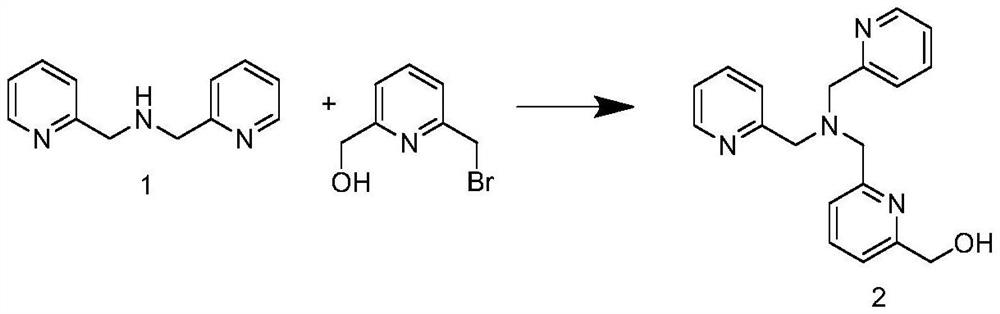

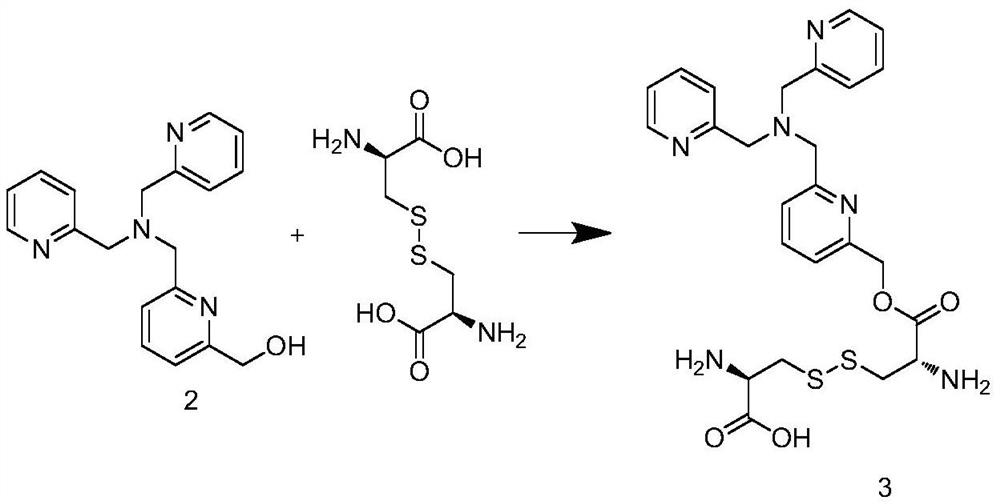

[0045] Step 2. Add 0.2 mol of 2-pyridinecarbaldehyde into 100 mL of absolute ethanol, add 0.2 mol of 2-picolylamine under stirring conditions, stir for 2 hours at room temperature, add 0.37 mol of sodium borohydride, and stir for 3 hours After the reaction, filter, and cool the filtrate to 0°C, add a hydrochloric acid solution with a mass fraction of 37 t...

Embodiment 2

[0052] The sorbent is made by the following steps:

[0053] Step 1. Add 2.5mL of n-pentanol, 7.9mL of tetraethyl orthosilicate and 30mL of n-hexane into a three-necked flask, stir for 5min, then add 3.9g of cetyltrimethylammonium bromide, 0.6g of urea and 30mL of distilled water , after magnetically stirring for 40 minutes, transfer the reaction product to a polytetrafluoroethylene reactor, and place it in an oven at 120°C for 4 hours. Centrifuge at a speed of 15min for 15min, and dry the obtained precipitate in an oven at 60°C for 12h, and finally bake it in a muffle furnace at 550°C for 6h to obtain a mesoporous carrier;

[0054] Step 2. Add 0.2mol of 2-pyridinecarbaldehyde into 100mL of absolute ethanol, add 0.2mol of 2-picolylamine under stirring conditions, stir at room temperature for 2h, add 0.41mol of sodium borohydride, and stir for 3h , after the reaction, filter, and cool the filtrate to 0°C, add a hydrochloric acid solution with a mass fraction of 37 to adjust the...

Embodiment 3

[0067] A copper-titanium corrosion solution for integrated circuits, comprising the following raw materials in mass percentage: 10% of sulfuric acid, 5% of nitric acid, 28% of acetic acid, 2% of potassium persulfate, 2% of hydrogen peroxide, 0.05% of the adsorbent in Example 1, and the balance for pure water;

[0068] The production process of the copper-titanium etching solution for integrated circuits comprises the following steps:

[0069] First add the required pure water to the batching tank, add potassium persulfate and hydrogen peroxide under stirring, and stir for 2 hours at a speed of 100r / min; then add sulfuric acid, nitric acid, and acetic acid to the batching tank in turn, and stir for 2 hours at a speed of 60r / min to obtain a mixture Pass the mixture into the filter and filter for more than 2 times, then add the adsorbent of Example 1, stir at constant speed for 20min, and obtain the copper-titanium etching solution for integrated circuits.

[0070] Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com