Difunctional Cu-based desulfurization catalyst, and preparation method and application thereof

A desulfurization catalyst and dual-function technology, applied in the field of dual-function Cu-based desulfurization catalyst and its preparation, can solve the problems of limiting catalyst application, easy loss of active components, affecting service life, etc., and achieves good H2S adsorption and excellent catalytic activity. and stable, efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of a bifunctional Cu-based desulfurization catalyst, comprising the steps of:

[0036] S1. Preparation of graphite phase carbon nitride: use one or more of urea, cyanamide, dicyandiamide, melamine, thiocyanate, and thiourea as precursors, and heat up in air or nitrogen atmosphere Keep at 500-600°C for 1-4 hours, and cool to room temperature to obtain graphite phase carbon nitride;

[0037] S2. Preparation of copper atoms embedded on the nitrogen-doped carbon nanosheet carrier: first, the graphite phase carbon nitride and bromine-containing phenolic compound prepared in step S1 are dispersed and dissolved in the mixed solution of ethanol and water, and then the corresponding Cu precursor and nitrogen-containing organic compound are added to the above solution, stirred and evaporated to dryness at 60-100°C to obtain an intermediate, and the evaporated intermediate is ground into a powder, placed in a heating device,...

Embodiment 1

[0043] Preparation of catalyst NC (without Cu precursor and nitrogen-containing organic compound):

[0044] Dissolve 2g of graphitic carbon nitride and 2g of tetrabromobisphenol A in a mixture of 20mL of water and 20mL of ethanol, stir and evaporate to dryness at 80°C. The evaporated sample was ground into powder, placed in a heating device, and heated to 800°C at a rate of 2.3°C / min under a nitrogen atmosphere, and pyrolyzed for 3 hours. After naturally cooling to room temperature, the synthesized samples were collected to obtain the catalyst, which was named NC.

Embodiment 2

[0046] Bifunctional Cu-based desulfurization catalyst CuN of the present invention 4 Preparation of / NC:

[0047] 2g graphite phase carbon nitride and 2g tetrabromobisphenol A were dissolved in 20mL water and 20mL ethanol mixture, then 0.248g Cu(NO 3 ) 2 ·3H 2 O and 0.18g porphyrin were added to the above solution, stirred and evaporated to dryness at 80°C. The evaporated sample was ground into powder, placed in a heating device, and heated to 800°C at a rate of 2.3°C / min under a nitrogen atmosphere, and pyrolyzed for 3 hours. After natural cooling to room temperature, the as-synthesized samples were collected to obtain a single-atom Cu-modified nitrogen-doped carbon catalyst with a nanolayered structure, named CuN 4 / NC.

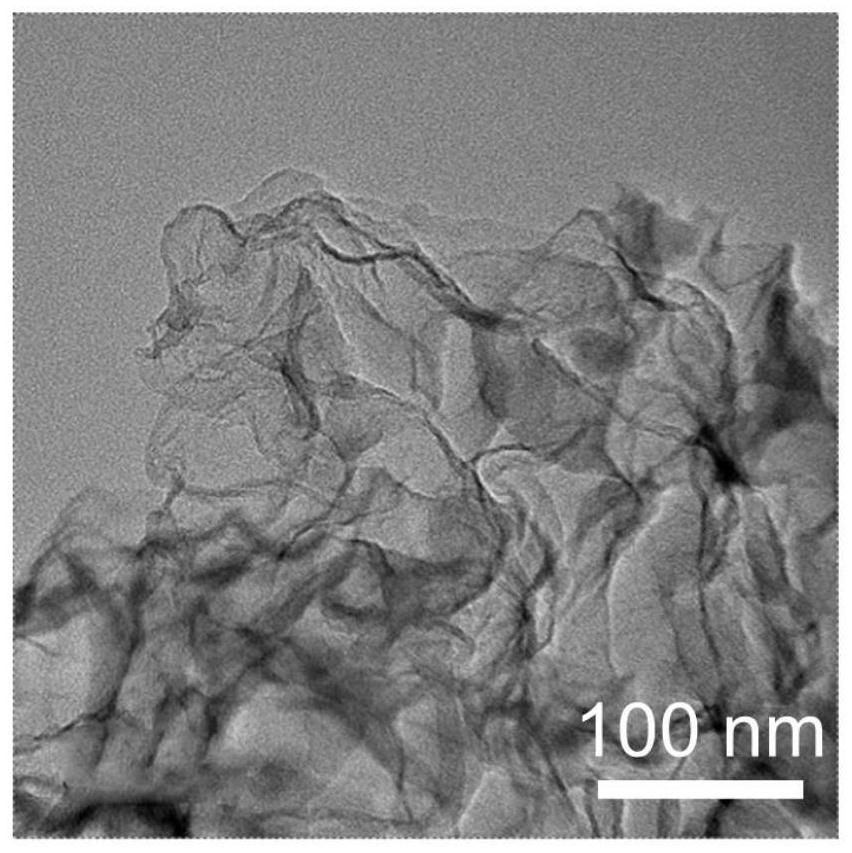

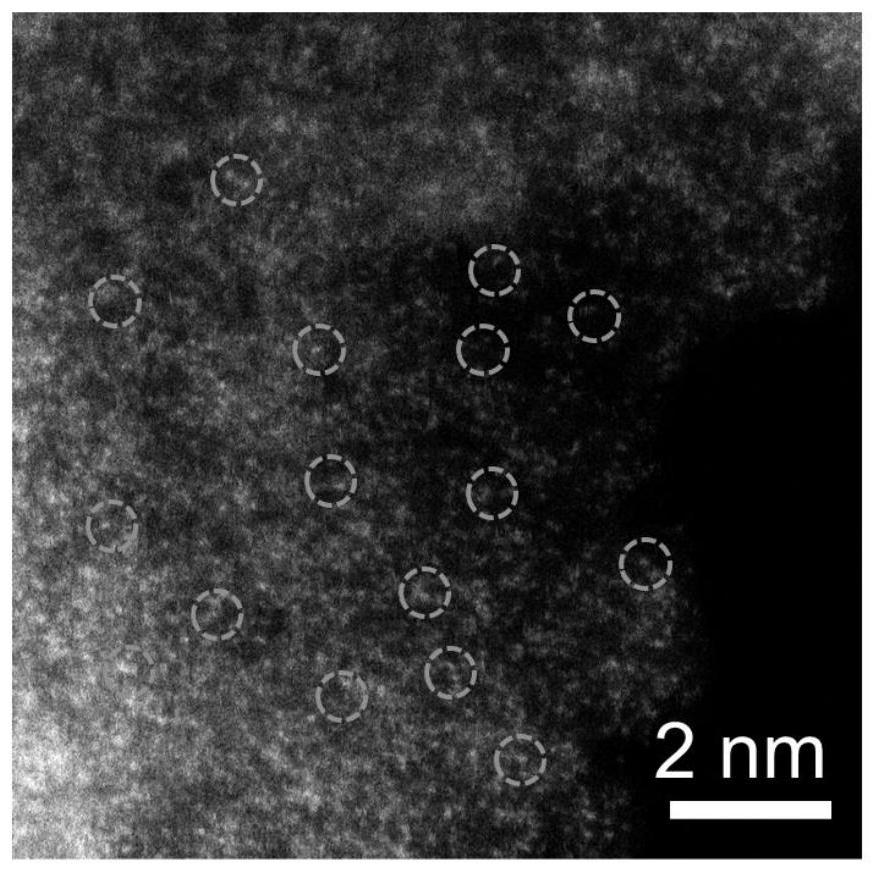

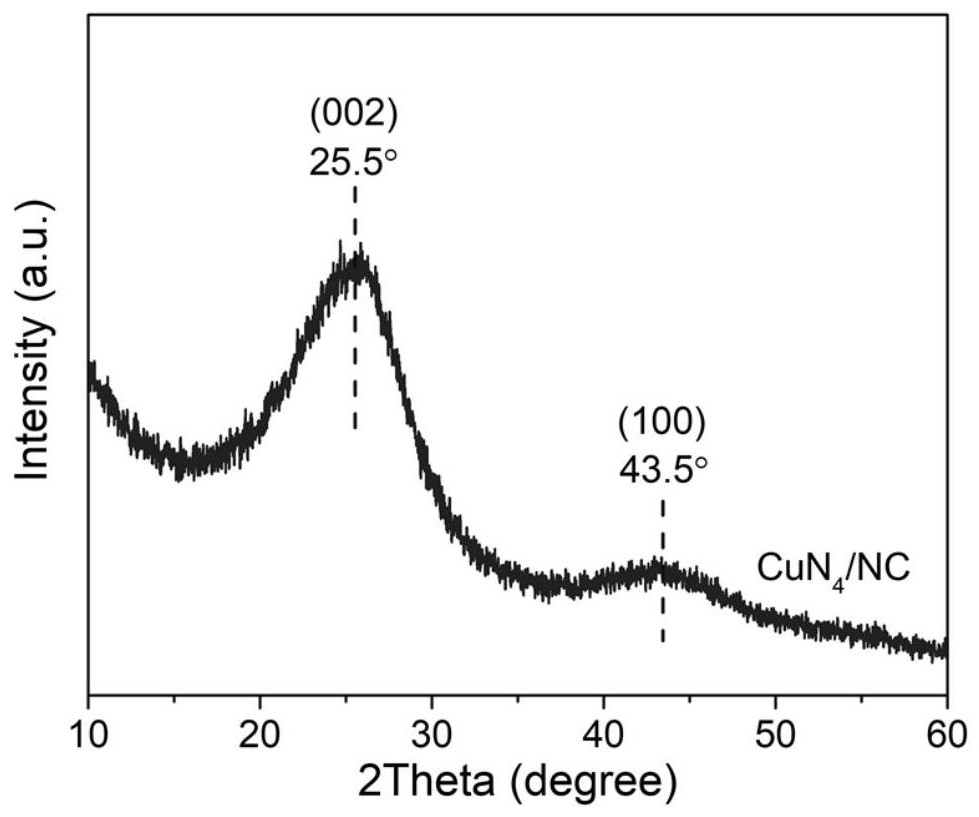

[0048] From Figure 1-Figure 4 It can be seen that the prepared CuN 4 Cu in the / NC catalyst presents a single-atom dispersion, no metal clusters or particles are found, and Cu and N form Cu-N 4 Coordination, Cu is uniformly distributed on the NC na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com