Preparation method and application method of silicon-containing rapidly-patterned block copolymer

A block copolymer and patterning technology, which is applied in the photolithographic process of patterned surface, optical mechanical equipment, instruments, etc., can solve problems such as thermal annealing, achieve high etching contrast, large difference in etching resistance, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Synthesis of Styrene Derivative Monomer Containing POSS Side Chain

[0064]

[0065] Heptaisobutylaminopropyl POSS (NH2-POSS, 9.59 g, 10 mmol) was dissolved in dichloromethane (DCM, 50 mL), then 1-hydroxybenzotriazole (HOBT, 1.86 g, 10 mmol) was added, 4 - Vinylbenzoic acid (1.48g, 10mmol), N,N-diisopropylethylamine (3.10g, 20mmol), 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt salt (EDCI, 1.86g, 10mmol). The reaction system was reacted at room temperature for 10 h, then dichloromethane (50 mL) was added for appropriate dilution, and distilled water (3×100 mL) was used to wash three times. After washing, put an appropriate amount of anhydrous magnesium sulfate into the organic phase to dry and remove water, and let it stand for 2-3 hours. After filtration, the solvent was removed by rotary evaporation to obtain 6.40 g of a white solid product (StNPOSS), with a yield of 64%.

Embodiment 2

[0067] PStNPOSS-b-PHFBMA silicon-containing fast patterned block copolymer and preparation method thereof

[0068]

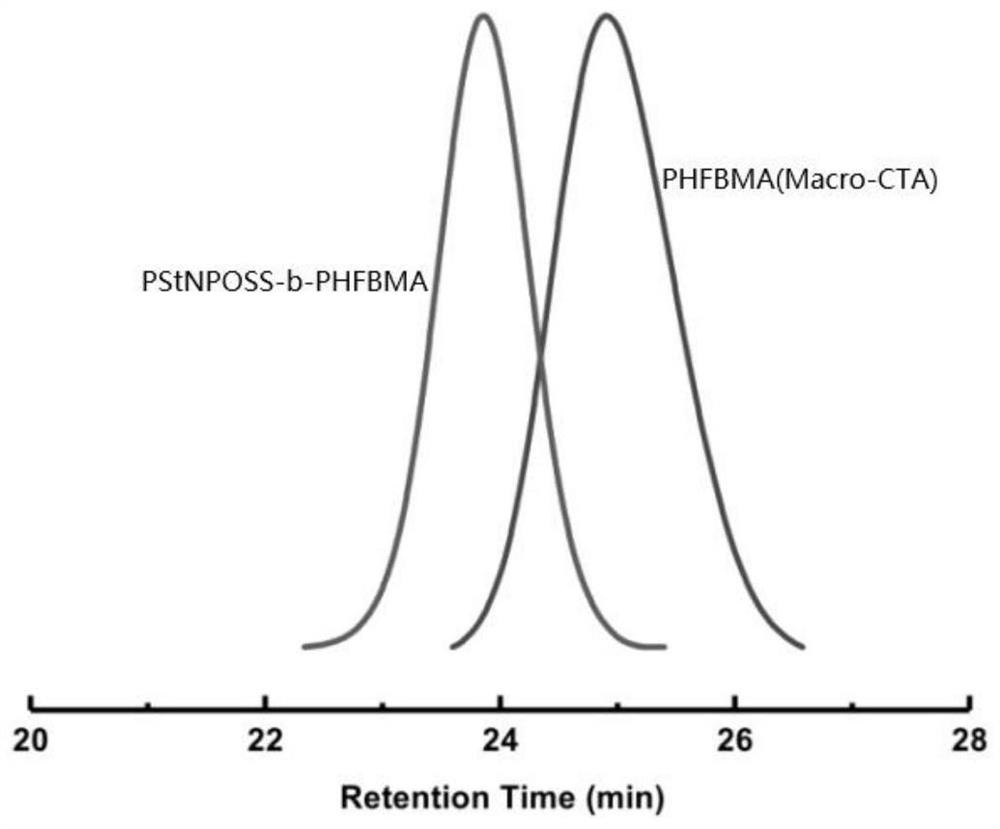

[0069] In a dry 100mL polymerization tube, add 1H,1H-perfluorobutyl methacrylate (HFBMA, 9.17g, 34.20mmol), cyanoisopropyl dithiobenzoate (CPDB, 378.8mg, 1.71mmol ), azobisisobutyronitrile (AIBN, 14mg, 0.086mmol) and hexafluoroisopropanol (HFIP, 25mL). Freeze-thaw cycles were performed three times to remove oxygen in the reaction system, and the polymerization tube was placed in an oil bath at 70° C. to seal the tube for 8 h. After the reaction, the polymerization tube was quickly placed in liquid nitrogen to quench, and then an appropriate amount of HFIP was added to the polymerization tube for dilution. The diluted solution was dropped into a large amount of n-hexane, and the precipitate was suction-filtered, and this was repeated three times. The obtained product was vacuum-dried at room temperature for 24 h to obtain 4.40 g of a pink powdery solid. The...

Embodiment 3

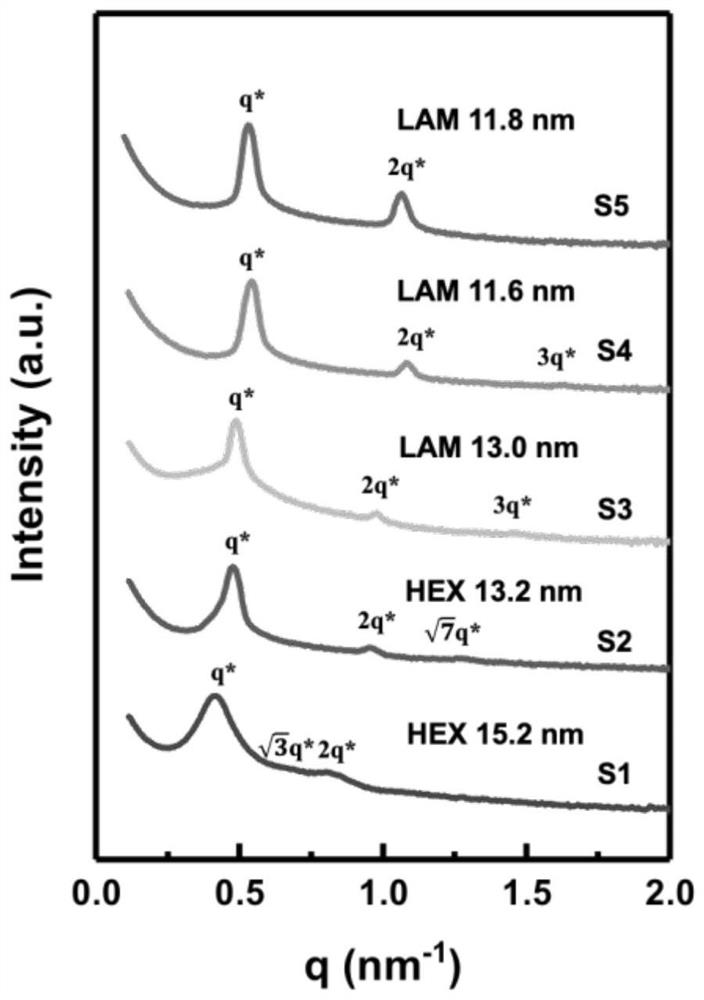

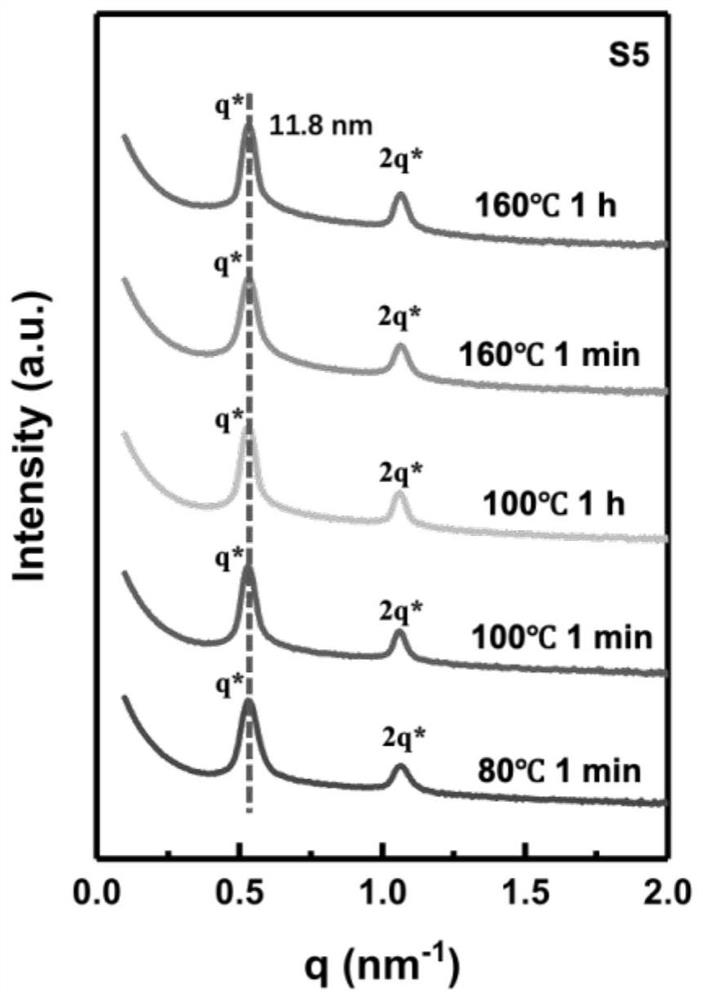

[0078] Self-assembly performance test of silicon-containing fast patterned block copolymer S1.

[0079] Figure 4 Schematic diagram of thermal assembly annealing. Such as Figure 4As shown, the obtained silicon-containing rapid patterning block copolymer S1 was dissolved in toluene to obtain a solution with a concentration of 0.5% mass fraction, which was spin-coated on a clean silicon wafer by a spin coater (4000rpm / min, 1min), and then dried in a vacuum. The solvent was removed by drying in the oven under vacuum for 2 h. The silicon chip is baked on a hot plate at 120°C, quenched with a cold plate after rapid annealing, and the obtained sample is further measured by SEM (scanning electron microscope). SEM measurement results such as Figure 5 As shown, the scale bar is 100 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com