A kind of stannous sulfide carbon composite material and its preparation method and application

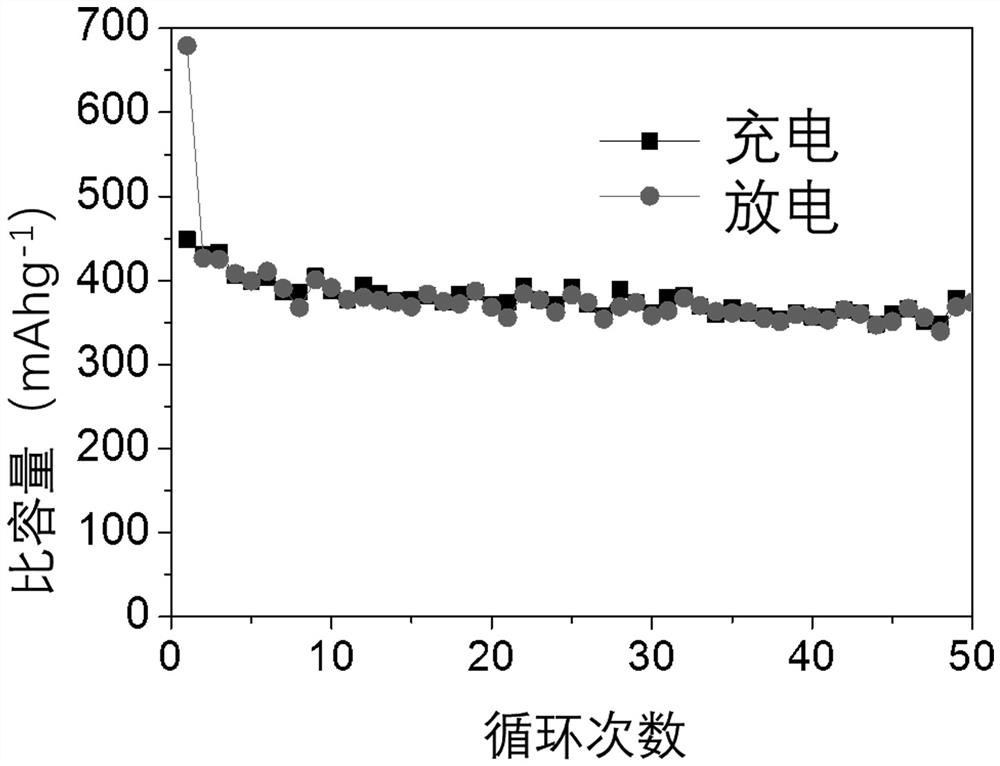

A technology of carbon composite materials and stannous sulfide, applied in chemical instruments and methods, carbon preparation/purification, tin compounds, etc., can solve the problems of complex structure, low conductivity, limited sodium storage capacity, etc., and achieve structural stability properties, suppress volume change, and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

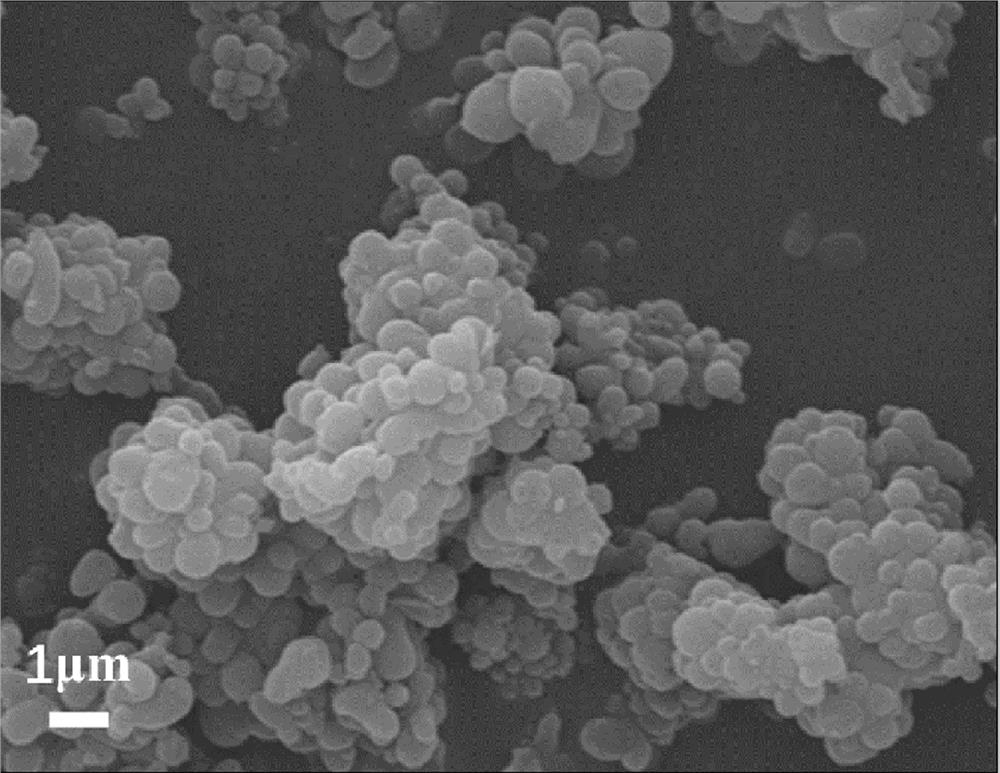

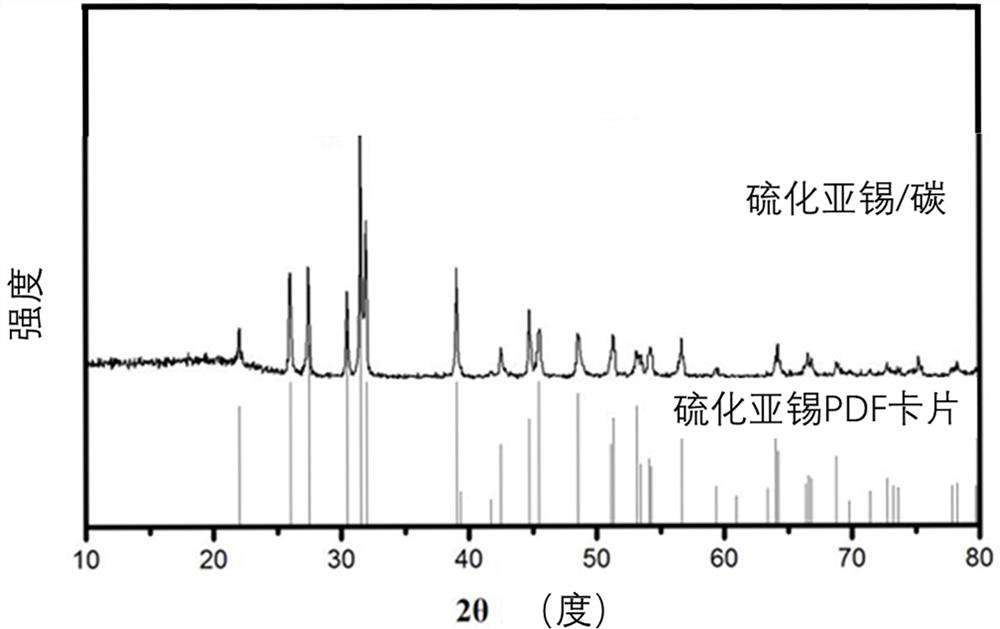

Embodiment 1

[0028] With 1.25g of SnCl 4 and 0.1g CTAB (cetyltrimethylammonium bromide) and 0.1g PVP (polyvinylpyrrolidone) in 30ml deionized water were fully stirred for 120min, then 2.7g sucrose and 0.48g oxalic acid were added to the solution, and after another 120min Stir in a water bath to form a clear solution. The hydrothermal reaction was carried out in a stainless steel autoclave with a volume of 50 mL and a polytetrafluoroethylene coating. The hydrothermal temperature was 200 ° C, and the temperature was kept for 10 hours. After completion, it was cooled to room temperature. After cleaning the product with distilled water and ethanol, it was dried in an oven at 60° C. for 12 hours to obtain a tin dioxide porous carbon composite material. The tin dioxide porous carbon composite was placed in a tube furnace under an argon atmosphere for 5 o C / min to raise the temperature to 650°C, keep the heat for 5 hours, and then cool down with the furnace to prepare the tin-carbon composite m...

Embodiment 2

[0033] With 2g of SnCl 4 Mix 0.4g CTAB and 0.8g PVP in 75ml deionized water for 120min, then add 5g sucrose and 0.48g oxalic acid into the solution, and then stir in a water bath for 120min to form a clear solution. The hydrothermal reaction was carried out in a stainless steel autoclave with a volume of 100mL and a polytetrafluoroethylene coating. The hydrothermal temperature was 180°C, kept for 16 hours, and cooled to room temperature after completion. After washing the product with distilled water and ethanol, it was dried in an oven at 60° C. for 12 hours. A tin dioxide porous carbon composite material was prepared. The tin dioxide porous carbon composite was placed in a tube furnace under an argon atmosphere for 5 o C / min to raise the temperature to 600°C, hold the temperature for 3 hours, and then cool down with the furnace to prepare the tin-carbon composite material. The tin-carbon composite material and sulfur powder were ground and mixed thoroughly in a mortar at ...

Embodiment 3

[0037] With 1.5g of SnCl 4 Mix 0.5g CTAB and 0.5g PVP in 75ml deionized water for 240min, then add 7g sucrose and 1.5g oxalic acid into the solution, and then stir in a water bath for 120min to form a clear solution. The hydrothermal reaction was carried out in a stainless steel autoclave with a volume of 100mL and a polytetrafluoroethylene coating. The hydrothermal temperature was 180°C, kept for 24 hours, and cooled to room temperature after completion. After washing the product with distilled water and ethanol, it was dried in an oven at 60° C. for 12 hours. A tin dioxide porous carbon composite material was prepared. The tin dioxide porous carbon composite was placed in a tube furnace under an argon atmosphere for 5 o C / min to raise the temperature to 650°C, hold the temperature for 3 hours, and then cool down with the furnace to prepare the tin-carbon composite material. The tin-carbon composite material and sulfur powder were ground and mixed thoroughly in a mortar at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com