Tissue engineering scaffold assembled by cell-loaded microgel as well as preparation method and application thereof

A tissue engineering scaffold and microgel technology, applied in the field of biomedical engineering, can solve the problems of difficult and effective transmission, single cell, insufficient flux, etc., and achieve the improvement of material transmission efficiency, high activity and function, and high material transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 1. Cell culture:

[0076] Taking the culture of human bone marrow-derived stem cells (hMSCs) as an example, the proliferation medium is composed of α-MEM (α-minimum Eagle's medium), 10% fetal bovine serum (FBS, Gibco), and the culture conditions are 37°C and 95% relative humidity with 5% CO 2 . Cell culture medium was changed every three days. Before use, the cells were washed with phosphate-buffered saline (PBS), placed in trypsin / EDTA solution for 5 minutes, and suspended in the medium for use.

[0077] 2. Preparation of cell-loaded microgel particles:

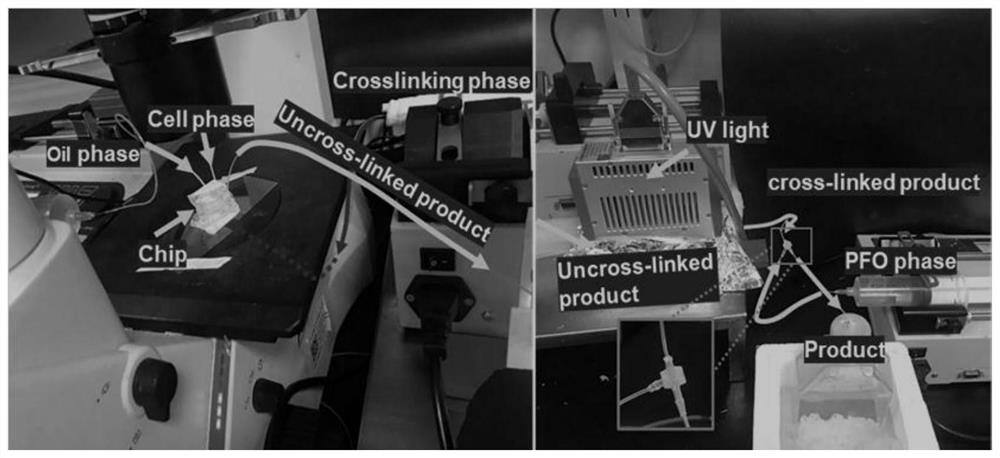

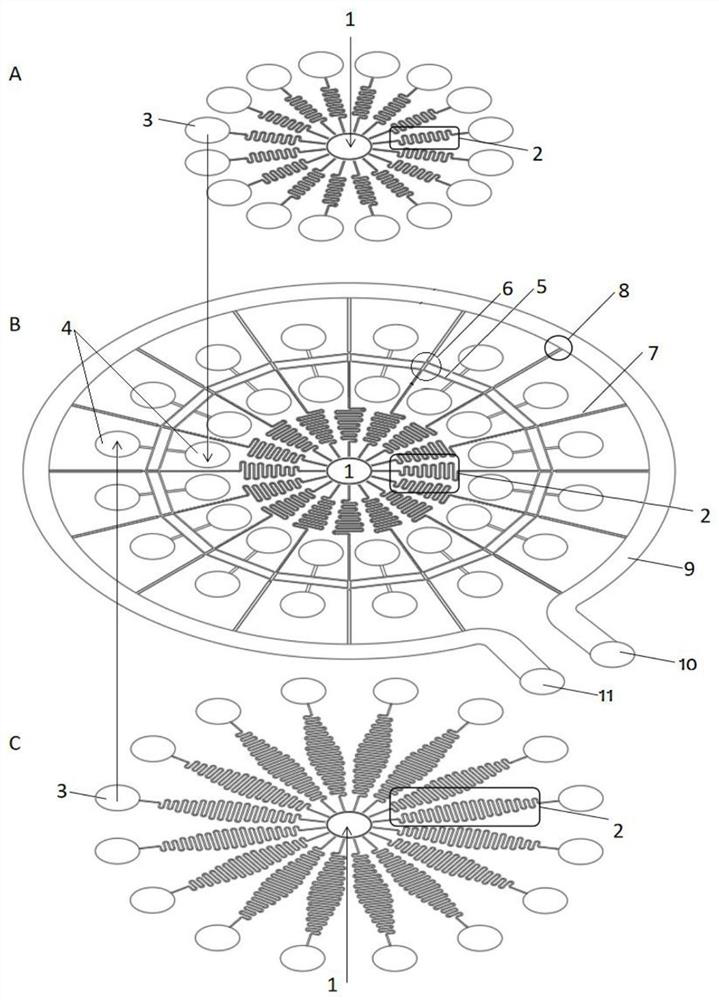

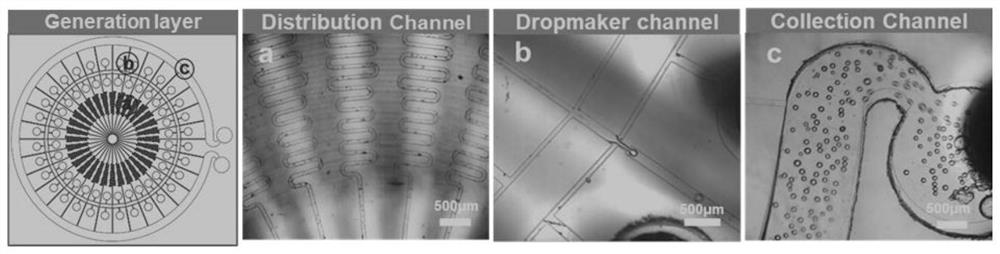

[0078] 0.1wt% LAP (lithium phenyl-2,4,6-trimethylbenzoylphosphonate), 1wt% AlgMA (sodium methacryloyl alginate) and 2.5wt% GelMA (methacrylic acylation Gelatin) precursor mixture was dissolved in α-MEM serum-free medium. Dispersing the hMSCs cells in the polymer prepolymer solution is called the cell phase (the concentration of the cell-loaded microgel is 9 × 10 6 Each / mL), connected to the sampling port of subs...

Embodiment 2

[0081] The cell-loaded microgel prepared in Example 1 was collected by centrifugation (1000 rpm), and then the cell-loaded microgel was densely packed by means of suction filtration. At this time, the dry weight of the microgel was 4 wt%. Then, rheological tests were carried out on the close-packed microgels, and the results showed that the close-packed microgels had shear-thinning properties and self-healing properties (such as Image 6 A and 6B), the rheological properties of the microgel meet the properties of extrudable printing as a bioink. Image 6 C demonstrates the extrudable advantage of microgels as inks. With the help of 3D printing equipment, microgels can be used as bioprinting inks to obtain different tissue structures, and biomimetic tissue printing can be performed, which will be beneficial to tissue construction (such as Figure 7 shown). The above results indicate that the microgels have printable properties.

Embodiment 3

[0083] After the close-packed microgels were printed in Example 2, in order to maintain the stability of the density structure, the microgels were extruded through a syringe and tested for stability. When larger, bending occurs (as in Figure 8 Shown in A), after secondary crosslinking (after calcium ion crosslinking), the close-packed microgel has structural stability (such as Figure 8 shown in B). A constant frequency (1 Hz) strain sweep was further tested to represent the shear yield characteristics of the shear modulus in response to shear strain ( Figure 9 A). It can be found that the microgels exhibit crossover at different strain amplitudes before and after crosslinking. The modulus (G′=G″) at the intersection point, the crosslinked microgel is significantly higher than that of the uncrosslinked microgel. The above results show that in the low strain range, the crosslinked microgel has Higher shear modulus. The shear modulus of the uncrosslinked microgel is an ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com