Method for extracting ganoderma lucidum sporocarp polysaccharide through fermentation pretreatment

A technology of Ganoderma lucidum fruiting body and pretreatment, which is applied in the field of extraction and separation of natural products, can solve the problems of waste of Ganoderma lucidum raw materials, interference in the investigation of extraction effect, large usage of fermentation strain liquid and toxic solvents, etc., so as to improve polysaccharide content and polysaccharide content Extraction rate, reducing energy consumption and production water consumption, eliminating fire and poisoning safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

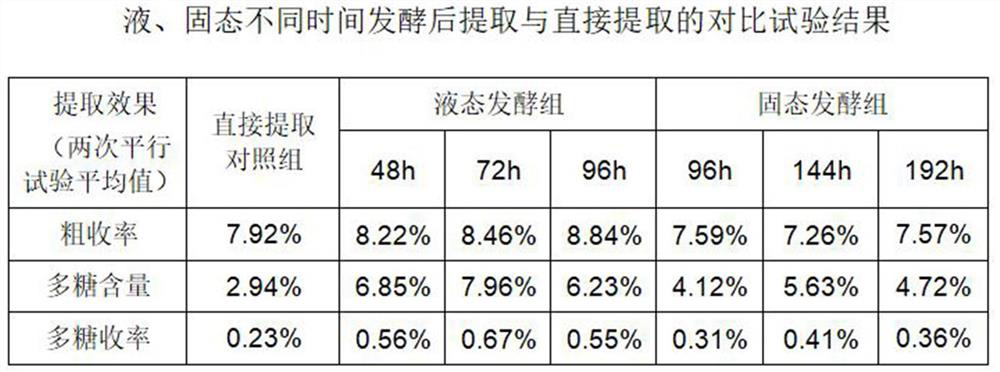

[0058] Example 1, according to the above-mentioned method, a comparative experiment of extracting Ganoderma lucidum fruiting body after liquid fermentation, solid state fermentation and direct extraction was established.

[0059] Take the ganoderma lucidum parent species, purify and expand the species according to the conventional method, and obtain the ganoderma strain culture solution for fermentation, take the ganoderma lucidum fruiting bodies, pulverize them, and sieve to obtain 20 mesh ganoderma powders for future use, wherein the ganoderma lucidum parent species and ganoderma lucidum fruiting bodies are Choose red sesame.

[0060] Liquid fermentation group: Weigh three parts of 20-mesh ganoderma lucidum powder, 100g each, put them into 2L Erlenmeyer flasks, add 100mL of purified water, fully infiltrate and sterilize by autoclaving at 121°C for 20min, and then put them in the purification bench Operation, add 900mL of purified water to the triangular flask, so that the to...

Embodiment 2

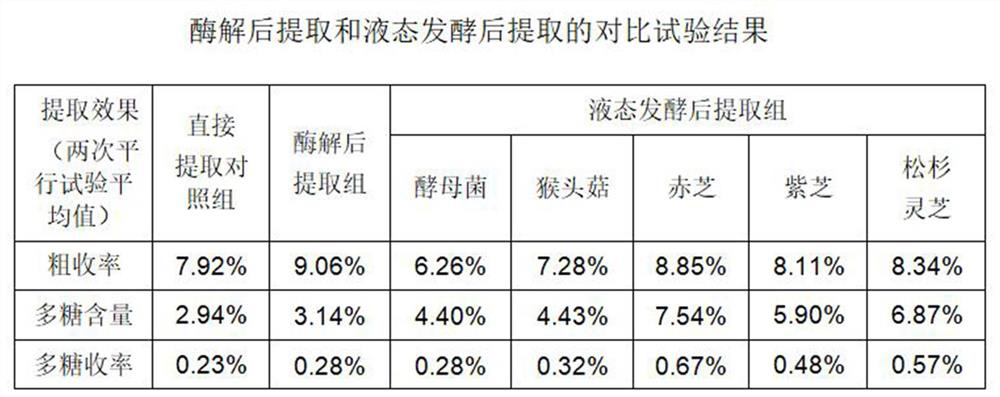

[0064] In Example 2, according to the above-mentioned method, a comparison test of extracting the fruiting body of Ganoderma lucidum after liquid fermentation and enzymatic hydrolysis was established.

[0065] Ganoderma lucidum fruiting body was crushed, sieved to obtain 20 mesh of Ganoderma lucidum powder, and set aside, wherein the ganoderma lucidum fruiting body was selected from Chizhi.

[0066] Extraction group after liquid fermentation: take the parent species of Chizhi, Zizhi, Ganoderma lucidum and Hericium erinaceus respectively, purify and expand the species according to the conventional method, and obtain the culture medium of four fermentation strains, and take another commercially available high-activity dry yeast , the highly active dry yeast was mixed evenly in 2% sugar water at a temperature of 38°C and activated for 30 minutes. The ratio of high active dry yeast to sugar water was 1:10 to prepare a yeast activation solution for later use. Repeat the test accord...

Embodiment 3

[0070] In Example 3, according to the above-mentioned method, a comparative test of extracting after different culture medium control treatments was established.

[0071] Take the ganoderma lucidum parent species, purify and expand the species according to the conventional method, and obtain the ganoderma strain culture medium for fermentation, take the ganoderma lucidum fruiting bodies, pulverize them, and sieve to obtain 20 mesh ganoderma powder, wherein the ganoderma lucidum parent species and ganoderma lucidum fruiting bodies are all selected from red lucidum ; Prepare 20 mesh fruit tree sawdust, set aside.

[0072] Ganoderma lucidum blank inoculation after shake flask extraction test group: Weigh 100g of 20-mesh Ganoderma lucidum powder, put it into a 2L Erlenmeyer flask, add 100mL of distilled water, fully infiltrate the Ganoderma lucidum powder, sterilize it by autoclaving at 115°C for 30min, and then in Operate in the purification workbench, add 900mL distilled water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com