Three-dimensional patterned porous graphene black body and preparation method and application thereof

A porous graphene, three-dimensional pattern technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve the problem of blackbody-like nano-micro structure that cannot form three-dimensional three-dimensional, difficult to achieve laser nano-micro structure fine processing, polymerization. The price of imide materials is high, and the effect of enhancing absorption and light-thermal conversion utilization, convenient storage and transportation, and no catalyst is required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The commercial lasers used in the present invention can be nanosecond lasers, picosecond lasers, femtosecond lasers, etc., carbon materials include but are not limited to shaped biomass porous carbon, carbon sponge, foam, gel, film, etc., wherein the biomass is porous Carbon is a carbon material prepared from biomass, such as plant stalks, fruit shells, etc., including but not limited to porous carbon, mesoporous carbon, coal, and activated carbon.

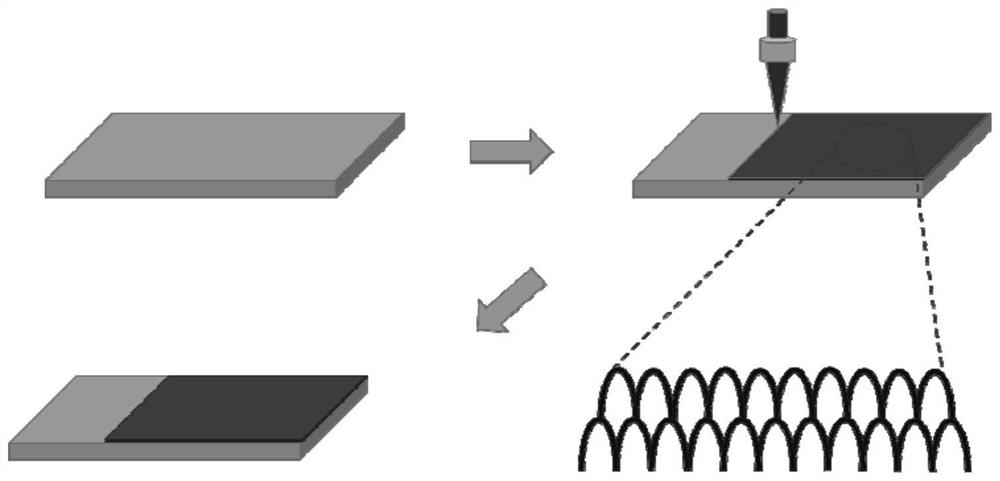

[0040] A method for preparing a three-dimensional patterned porous graphene-like black body prepared by a short-pulse laser-induced processing method, the specific steps are as follows:

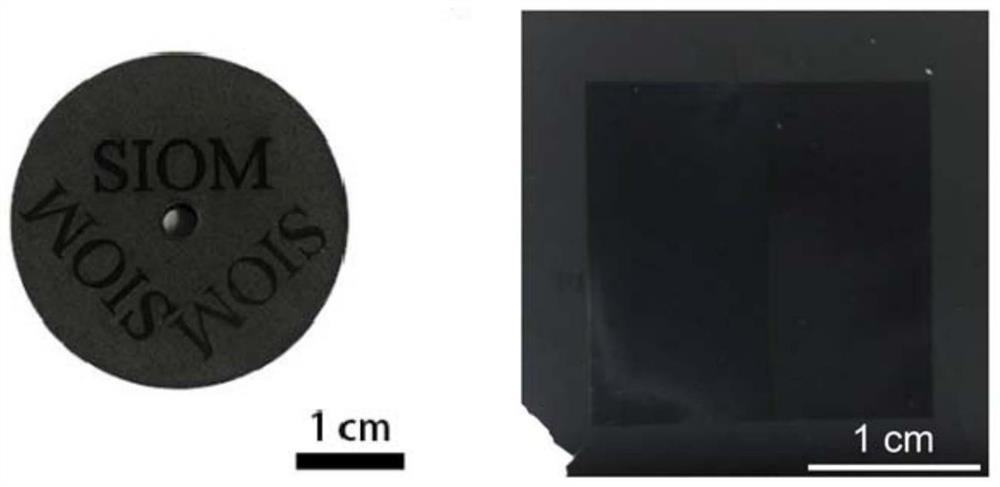

[0041] (1) Using laser processing technology to induce porous graphene-like black bodies: process the formed carbon material into a disc shape with a diameter of 30 mm, and then use a fixing device to fix it on the substrate. The fixing device here includes but is not limited to tape, Clamping tooling, etc.; flat substrates include but are...

Embodiment 2

[0045] Such as Figure 6 As shown, the application of a hydrophilic porous graphene-like black body prepared by laser processing method in seawater desalination, specifically, a container with a dome with a diameter of 8 cm is used as a fresh water collection device; the hydrophilic fiber Cloth and other hydrophilic materials are coated on the surface of cylindrical heat-insulating foam, and placed in a circular plastic beaker with a diameter of 5 cm that is filled with water to be treated; the hydrophilic porous graphene-like blackbody material prepared by the present invention is processed into a diameter 5 cm round, making it in decryption contact with the hydrophilic fiber cloth; under the sunlight, the porous graphene-like black body absorbs light and converts the light into heat to heat and evaporate the water absorbed by the hydrophilic fiber cloth at the bottom, separating Thermal foam plays the role of heat management, so as to realize seawater desalination, sewage tr...

Embodiment 3

[0048] Such as Figure 7 As shown, the application of a three-dimensional patterned porous graphene-like black body prepared by short-pulse laser processing method in photothermal catalysis and photoelectrocatalytic degradation of organic matter, specifically, a laser-induced three-dimensional pattern with a size of 1*1 cm The graphene-like black body material is used as the working electrode and placed in a circular plastic beaker with a diameter of 5 cm to be treated with organic wastewater; a two-electrode system is used, with graphite as the counter electrode, and the light is enhanced to electrochemically catalyze the degradation of organic matter.

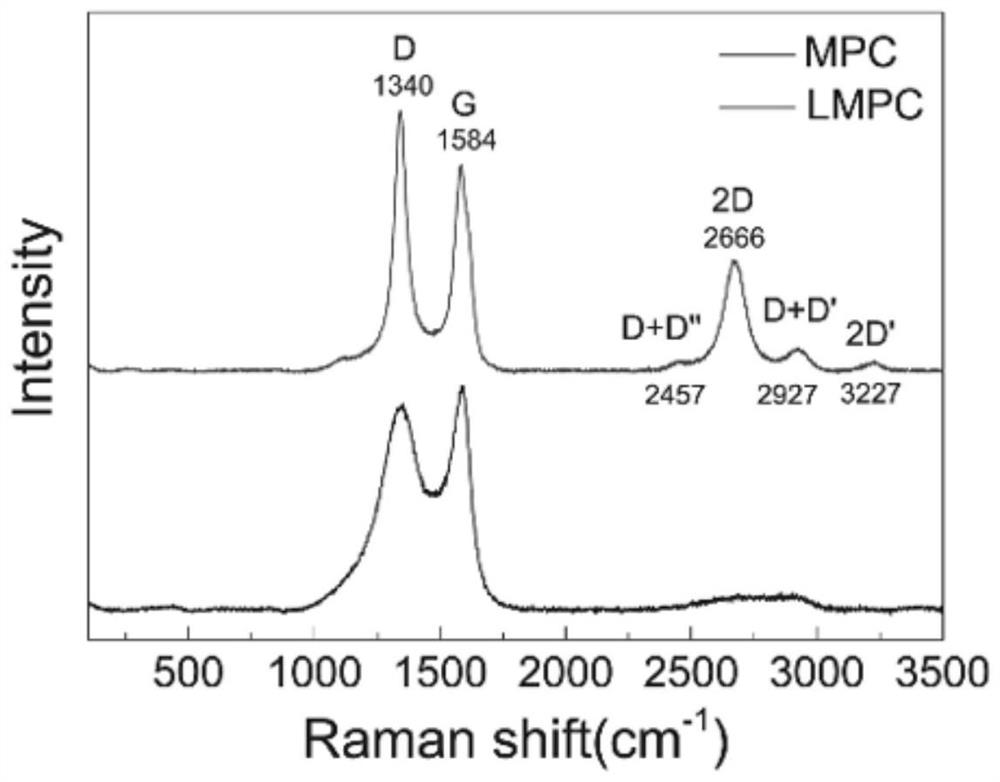

[0049] The principle of the invention is to use laser to induce graphitization transformation of carbon materials, and induce the formation of graphene-like black bodies under laser irradiation. During the whole process, part of the carbon is gasified to form a large number of porous structures. The graphene-like black body w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com