Propylene recovery method and equipment, epoxidation reaction product separation method and device, epoxidation method and epoxidation system

A technology of epoxidation reaction and propylene, which is applied in epoxidation reaction product separation device, epoxidation reaction product separation, epoxidation system, and epoxidation field, can solve the problems of high energy consumption and poor economy, and achieve Low recovery energy consumption, lower propane content, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

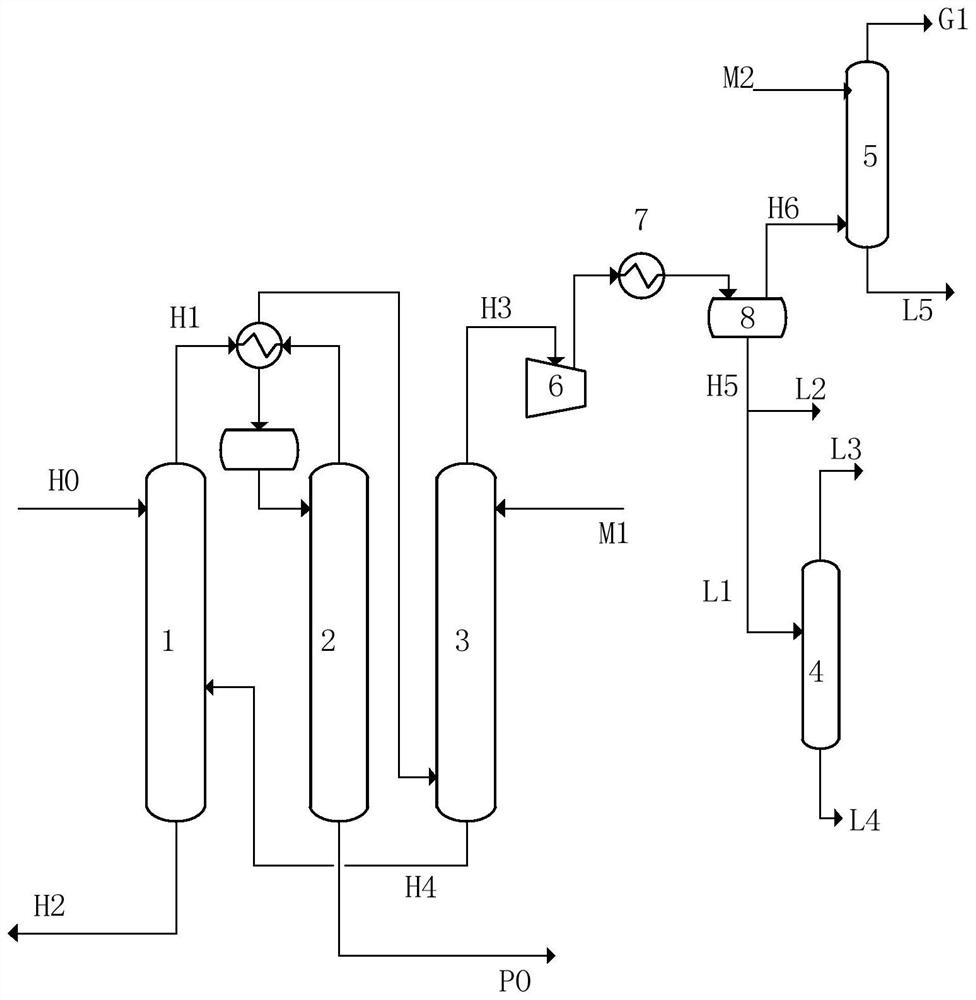

[0132] This embodiment adopts figure 1 The separation scheme shown treats an epoxidation reaction product H0 having the following composition: based on the total amount of epoxidation reaction product H0, the epoxidation reaction product H0 contains: 14% by weight propylene oxide, 7.2% by weight % propylene, 0.6% by weight propane, 63.5% by weight methanol, 0.2% by weight hydrogen peroxide, 13.4% by weight water.

[0133] (1) The epoxidation reaction product H0 enters the de-epoxypropane tower 1 for distillation, and the distillate H1 containing propylene oxide and unreacted propylene and the bottom stream H2 containing methanol are obtained from the top of the tower. The temperature at the top of the epoxide removal tower 1 is 69° C., the pressure at the top of the tower is 0.1 MPag, and there is no reflux. The theoretical plate number of the epoxide removal tower 1 is 35, and the feed is fed from the top of the tower.

[0134] The content of propylene oxide is 0.005% by wei...

Embodiment 2

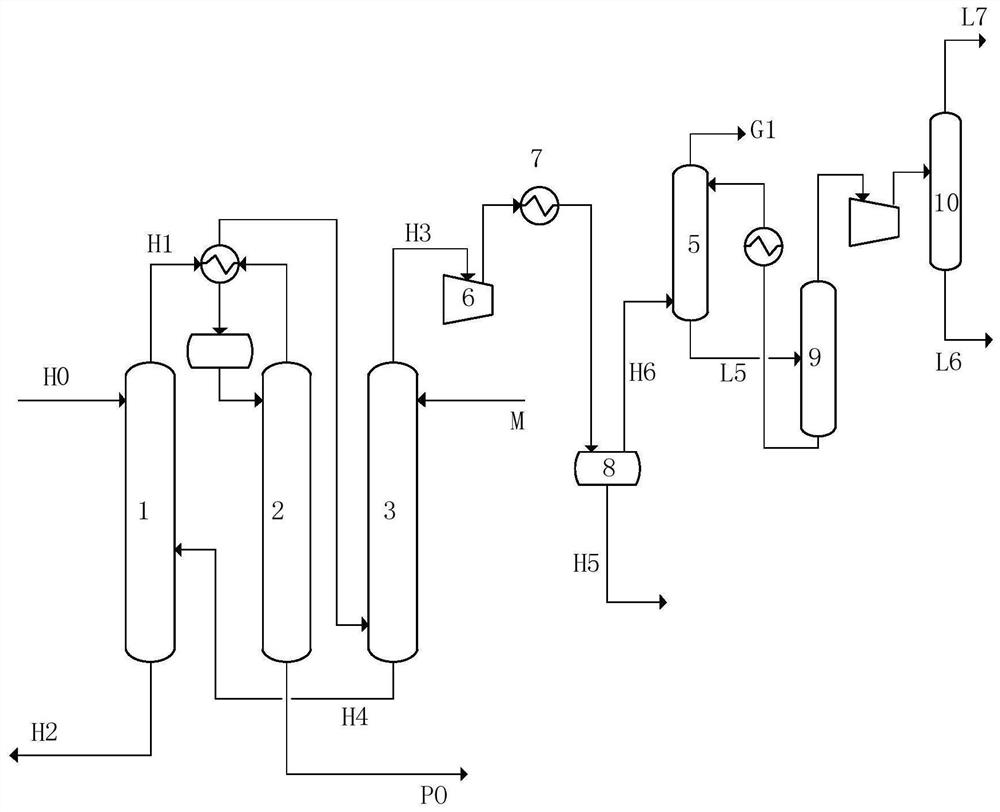

[0172] The epoxidation reaction product H0 is separated by the same method as in Example 1 to obtain reclaimed propylene. The difference is that in step (4), the compression ratio of the compressor 6 is 11.8, and the pressure in the buffer tank 8 is kept at 1.3 MPag at 40°C. The content of propane in the liquid phase separation stream H5 was 43% by weight, based on the total amount of propane in the propylene-containing process stream H3.

[0173] Based on the total amount of the second liquid phase separation stream L2 and the propylene refining stream L3, the content of methanol is 5.5% by weight, the content of propylene is 92.4% by weight, the content of propane is 1.9% by weight, and the content of oxygen is 0.1% by weight , the nitrogen content was 0.1% by weight. The content of propane in the propylene absorbing stream L5 was 1.4% by weight.

[0174] Based on the total amount of propylene in the epoxidation reaction product H0, the total recovery of propylene was 99.7...

Embodiment 3

[0177] Adopt the method identical with embodiment 1 to separate epoxidation reaction product H0, obtain reclaiming propylene, difference is, in step (5), the operating condition of propylene refining tower 4 is:

[0178] The temperature at the top of the propylene refining tower 4 was 42° C., the pressure at the top of the tower was 1.7 MPag, and the reflux ratio was 5. The theoretical plate number of the propylene refining column 4 is 100, and the theoretical plate number of the feeding position of the first liquid-phase separated stream L1 is 55.

[0179] The content of propane in the refined propylene stream L3 is 4.4% by weight, based on the total amount of propylene in the first liquid phase separation stream L1, the content of propylene entering the propane stream L4 is 4.5% by weight.

[0180] The second liquid phase separation stream L2, the propylene refining stream L3 and the propylene absorption stream L5 are used as recovered propylene.

[0181] Based on the total...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap