Treatment method of waste containing organic phosphorus chlorinated hydrocarbon

A treatment method, chlorinated hydrocarbon technology, applied in the direction of phosphorus compounds, chemical instruments and methods, calcium/strontium/barium chloride, etc., can solve the problem that the combustion temperature control is difficult to meet the requirements of hazardous waste incineration, the difficulty of processing temperature control is increased, Unreasonable organization and other problems, to achieve the effects of stable and controllable pyrolysis reaction, safe and controllable treatment process, and lower pyrolysis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

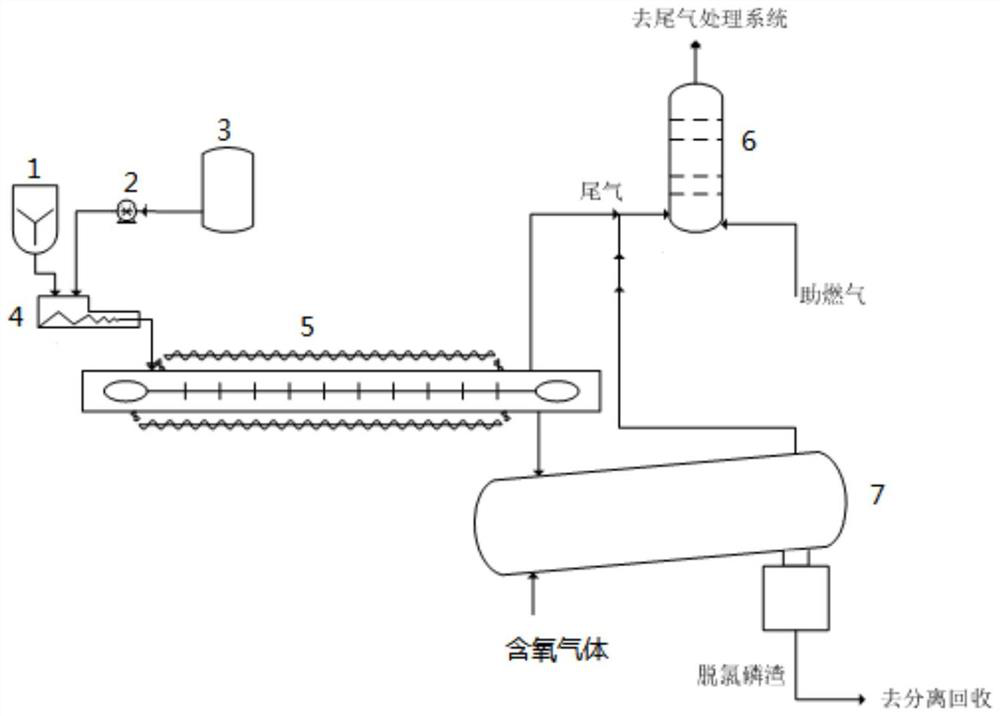

[0054] (1) start thermal cracking reactor 5 (scraper type reaction furnace, adopt electric heating temperature control), thermal cracking reactor 5 is warmed up to 650 ℃; Start the agitator and material kneader 4 of solid feeding hopper 1, lime ( Calcium oxide content 92.1%) enters in the pyrolysis reactor 5 through material kneader 4 from solid feed hopper 1 with the speed of 420g / h; Open waste liquid pump 2, make 1,1,1,3,3-pentachloropropane (HCC-240fa) Waste liquid (total chlorine content 62.41%, total phosphorus content 2.60%) enters thermal cracking reactor 5 through material kneader 4 at a speed of 660g / h; waste liquid and lime continuously enter thermal cracking reactor 5 Among them, react in thermal cracking reactor 5, and material residence time is 4.8 hours, and the material that reaction obtains is separated at thermal cracking reactor 5 outlets, and gas phase product is discharged into combustion reactor 6 from the top of thermal cracking reactor 5, and other produc...

Embodiment 2

[0059] (1) start thermal cracking reactor 5, thermal cracking reactor 5 is heated up to 680 ℃; Lime (calcium oxide content 90.0%) and organic phosphorus chlorinated hydrocarbon waste (total chlorine content 46.63%, total phosphorus content 6.48% ) with a mass ratio of 1.85:3 in the solid feeding hopper 1 beforehand, start the material kneader 4, and the mixture of lime and organophosphorus chlorohydrocarbon waste is kneaded from the solid feeding hopper 1 through the material at a speed of 1730g / h Machine 4 enters in thermal cracking reactor 5, mixes and reacts in thermal cracking reactor 5, and material residence time is 3.03 hours, and the material that reaction obtains is separated in thermal cracking reactor 5 outlets, and gas phase product is from thermal cracking reactor 5 The upper part is discharged into the combustion reactor 6, and other products enter the decarbonization reactor 7 (horizontal incinerator) through the feed bin of the thermal cracking reactor 5;

[00...

Embodiment 3

[0064] (1) start thermal cracking reactor 5, thermal cracking reactor 5 is warmed up to 600 ℃; Start the agitator and material kneader 4 of solid addition hopper 1, calcium hydroxide (calcium hydroxide content 76.60%) is with 580g / The speed of h enters in the pyrolysis reactor 5 through material kneader 4 from solid feed hopper 1; Open waste liquid pump 2, make HCC-240fa waste liquid (62.41% of total chlorine content, 2.60% of total phosphorus content) with 560g / h The speed enters the thermal cracking reactor 5 through the material kneader 4; HCC-240fa waste liquid and calcium hydroxide continuously enter in the thermal cracking reactor 5, and react in the thermal cracking reactor 5, and the material residence time is 4.33 hours. The material obtained is separated at the thermal cracking reactor 5 outlet, and the gas phase product is discharged into the combustion reactor 6 from the top of the thermal cracking reactor 5, and other products enter the decarbonization reactor 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com