Method for preparing three-dimensional metal lithium negative electrode by using MOFs derivative

A technology of metal lithium and derivatives, applied in negative electrodes, active material electrodes, lithium batteries, etc., can solve the problems of changing the lithophilicity of the substrate, poor lithophilicity, etc., to promote the pace of research and development and practice, high specific surface area, delay The effect of the initial nucleation time point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

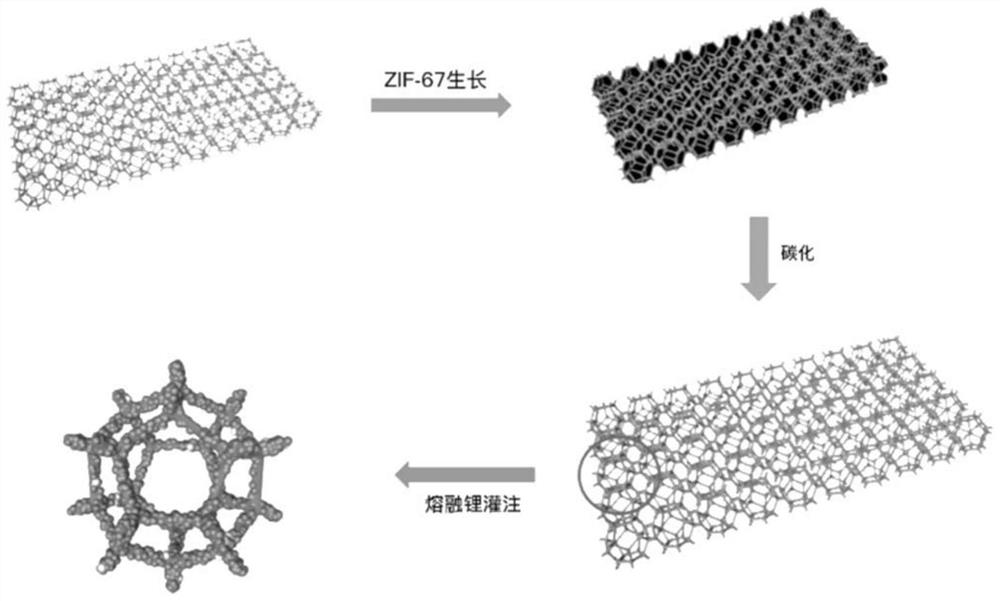

[0031] Example 1 Preparation of a three-dimensional metal lithium negative electrode:

[0032] The metal salt used is cobalt nitrate, the organic solvent is methanol, the organic ligand is 2-methylimidazole, and the three-dimensional porous skeleton is foam nickel.

[0033] S1, 1 mmol of hexahydrate (0.291 g) was dissolved in 25 mL of methanol, and the resulting solution was placed on a magnetic stirrer for stirring for 5-10 min;

[0034] S2, 4 mmol of 2-methylimidazole (0.328 g), in solution of S1, continued to stir well, to stand for 24 h, to give a methanol solution containing metal organic frame material ZIF-67;

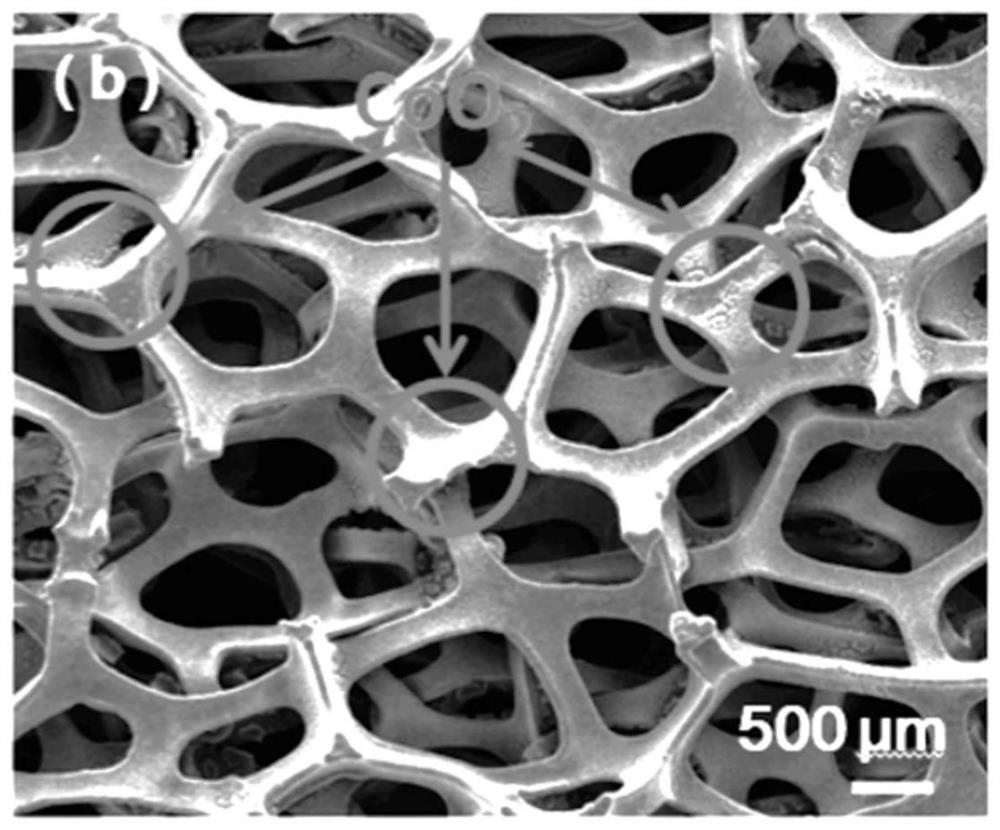

[0035] S3, pretreatment of foam nickel: placed foam nickel, 5-10 ml of acetone, 5-10 ml of water, 5-10 ml deionized water, each ultrasound 10-15min, then placed in a vacuum drying tank at 60 ° C 1-2h;

[0036] S4, soak the pretreated foam nickel in methanol containing ZIF-67;

[0037] S5, the resulting mixed solution was placed on a magnetic stirrer for stirring for ...

Embodiment 2

[0041] Example 2 Battery performance test of three-dimensional metal lithium negative electrode

[0042] S1, the preparation of lithium lithium phosphate electrode sheet: First, use N-methylpyrrolidone (NMP) as a solvent, using LIFEPO 4 / Conductive carbon black / adhesive PVDF (mass ratio is 8: 1: 1) Preparation of iron phosphate electrode slurry. The resulting slurry was mixed for 20-30 min; the obtained uniform slurry was applied to the aluminum aggregate fluid, followed by vacuum 12 h at 120 ° C.

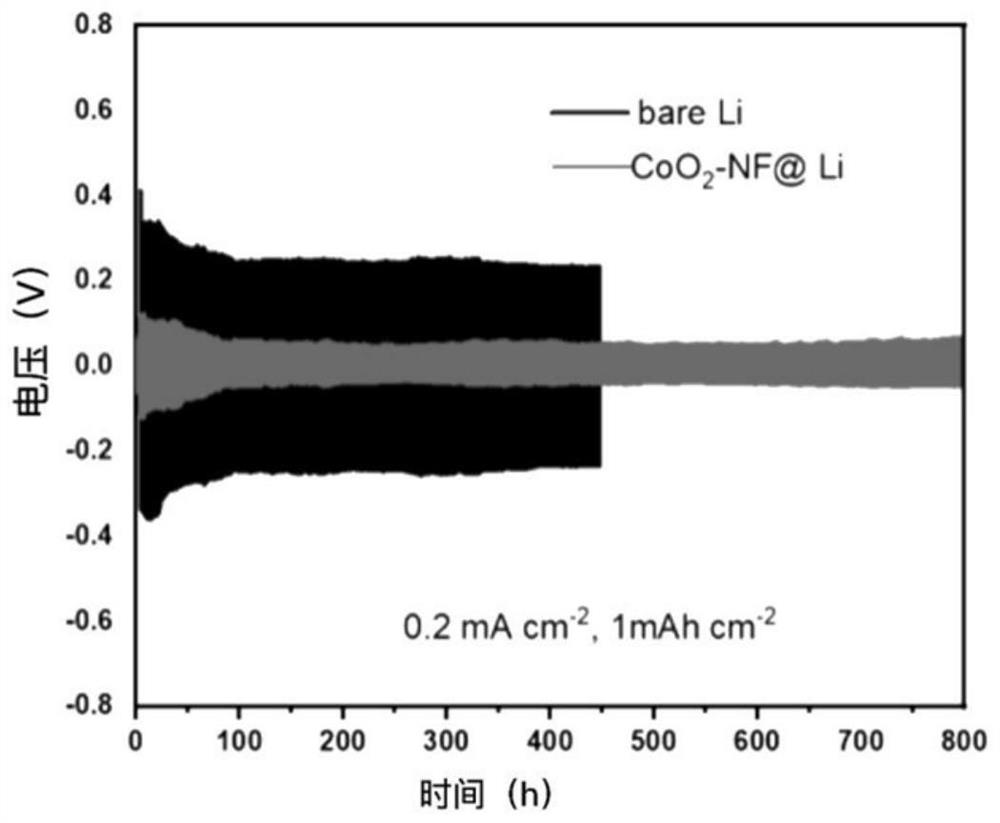

[0043] S2, in a glove box filled with argon (H 2 0, O 2 The order of the composite metal lithium negative electrode / commercial diaphragm / composite metal lithium negative electrode / commercial diaphragm / composite metal lithium magazine, the lithium-lithium magazine, and the full battery is prepared, respectively, and put it from blue The battery tester is tested at room temperature. The test results are respectively image 3 and Figure 4Indicated.

[0044] further, image 3 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com