Bacteria enzyme compound feed additive as well as preparation method and application thereof

A feed additive and composite technology, applied in application, animal feed, animal feed, etc., can solve the problems of large amount of addition, weak antibacterial effect, unstable use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation method of coated lactic acid bacteria

[0029] 1.1 The preparation steps of Enterococcus faecium HEW-A588 fermentation broth are as follows:

[0030] Take the glycerol tube of Enterococcus faecium HEW-A588 preserved in liquid nitrogen, dissolve it in a water bath at 37°C for 25 minutes, separate and purify it by streaking on the MRS plate, and culture it at 37°C for 48 hours; pick and grow on the plate in the sterile room Vigorous single colony, use an inoculation loop to inoculate on a fresh MRS slant, and incubate at 37°C for 18 hours; add 2.0mL sterilized physiological saline to the test tube in a sterile room, scrape the bacterial lawn with an inoculation loop, and make a bacterial suspension; Take 0.8mL of the bacterial suspension and inoculate it into a 1L Erlenmeyer flask filled with 300mL of shaker medium, pH 6.8, 37°C, 150r / min shaking culture for 6.5h, to obtain a seed solution, the number of viable bacteria is greater than 9.0×10...

Embodiment 2

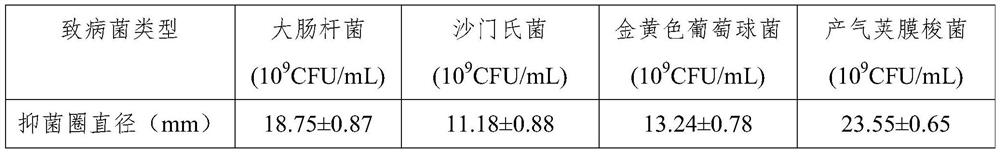

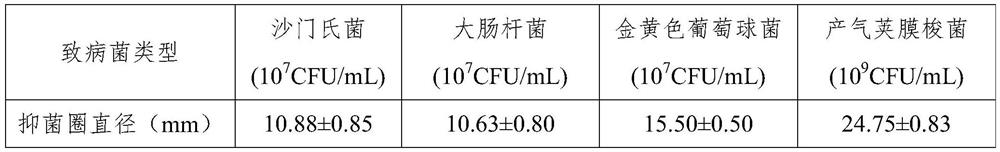

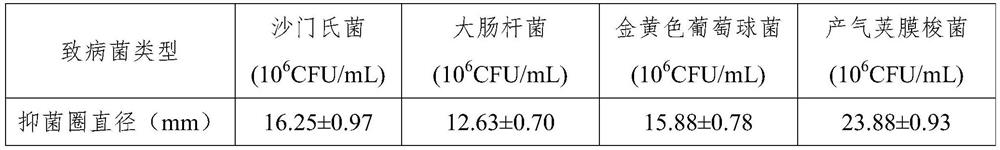

[0042] Embodiment 2: Bacteriostasis experiment of 3 kinds of living bacteria and glucose oxidase in bacterial enzyme composite additive

[0043] 2.1 Preparation of pathogenic bacteria suspension

[0044]In the sterile room, 20 μL of pathogenic Escherichia coli, Salmonella and Staphylococcus aureus purchased from glycerol tubes were inoculated into 50 mL liquid nutrient medium (composition by mass percentage: peptone 0.3%, beef extract 1%) , sodium chloride 0.5%, the balance is water, adjust the pH value to 7.0, and sterilize at 121°C for 30min), place it in a vibrating shaker and culture it dynamically at 200r / min for 18h, and make Escherichia coli, Salmonella and golden yellow respectively Staphylococcus suspension, stored in a refrigerator at 4°C, for later use.

[0045] In the sterile room, the purchased Clostridium perfringens was first streaked from the glycerol tube to the TSC (tryptone-sulfite-cycloserine agar medium) plate with an inoculation loop, and obtained after ...

Embodiment 3

[0076] Embodiment 3: A kind of preparation method of bacterium-enzyme compound feed additive

[0077] The bacterium-enzyme compound feed additive contains the following components in weight percentage: 20% of coated lactic acid bacteria, 15% of bacteriostatic Bacillus subtilis, 5% of Clostridium butyricum, 10% of glucose oxidase, 30% of bentonite, Talc 20%.

[0078]The number of live bacteria of the above-mentioned coated lactic acid bacteria is 2.0×10 10 CFU / g, the number of live bacteria of antibacterial Bacillus subtilis is 1.0×10 11 CFU / g, the number of live bacteria of Clostridium butyricum is 1.0×10 10 CFU / g; the enzyme activity of glucose oxidase is 15000U / g.

[0079] Bacteriostatic Bacillus subtilis, Clostridium butyricum, and glucose oxidase are all commercially available products.

[0080] See Example 1 for the specific preparation method of coated lactic acid bacteria.

[0081] The preparation steps of bacterium-enzyme compound feed additive are: the bentonite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com