Method for producing DHA by using schizochytrium limacinum fermentation

A technology of Schizochytrium and fermentation medium, which is applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, and can solve the problems of low biomass yield and failure to meet the needs of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Configure the activation medium: add 100ml of the activation medium to the 500ml conical flask. The components of the activated medium are: glycerol 40g / L, glutamic acid 30g / L, yeast extract 6g / L, dihydrogen phosphate Potassium 6g / L, magnesium sulfate 6g / L, metal ion solution 1g / L, vitamin solution 1g / L. Sterilize at 121°C for 30 min, and cool for later use.

[0032] 2. Configure the seed bottle medium: add 200ml of seed culture liquid base to the 1000ml conical flask. The components of the seed culture liquid base are: glycerol 50g / L, glutamic acid 30g / L, yeast extract 9g / L, phosphate dibasic Potassium hydrogen 2.1g / L, magnesium sulfate 5g / L, diammonium hydrogen phosphate 1g / L, metal ion liquid 1g / L, vitamin liquid 1g / L. Sterilize at 121°C for 30 min, and cool for later use.

[0033] 3. Inoculate the above-mentioned activated culture solution into fresh liquid seed medium again, with an inoculation amount of 5%, at 28° C., 150-220 rpm, and cultivate for 24 hours t...

Embodiment 2

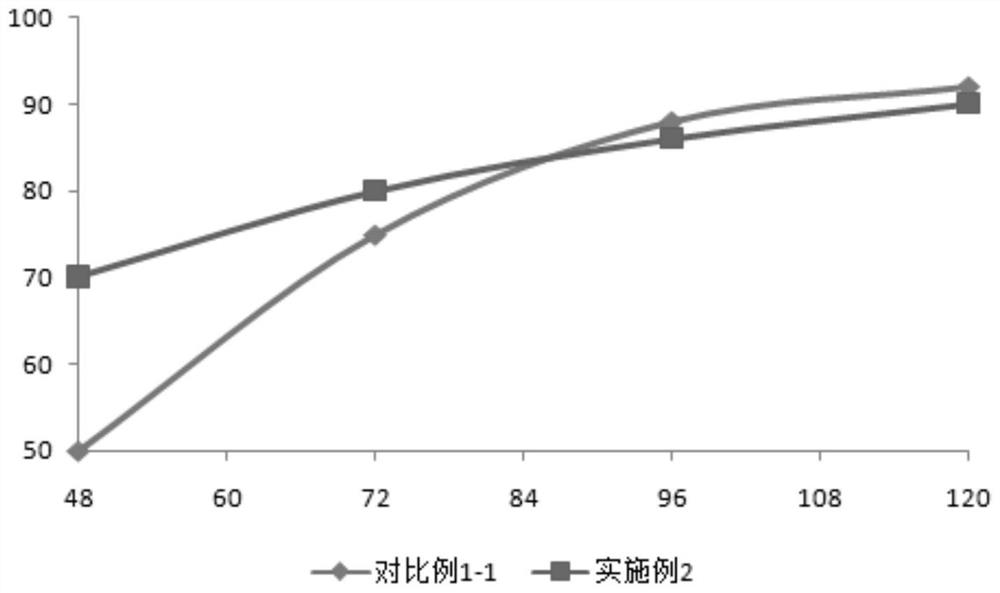

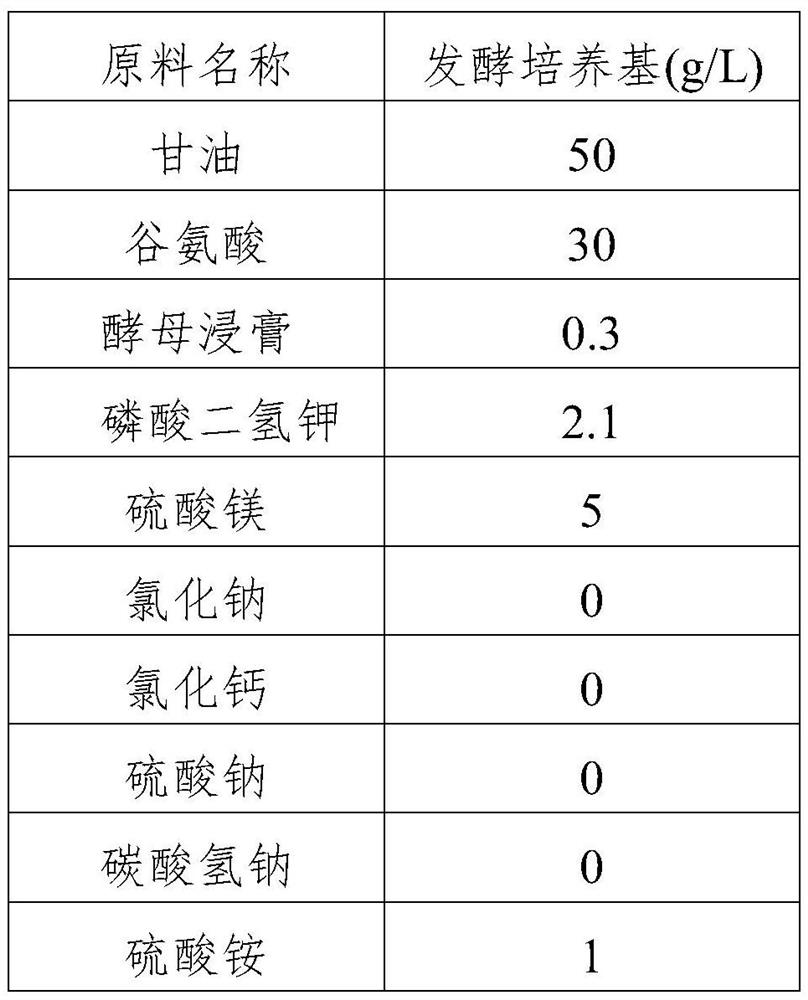

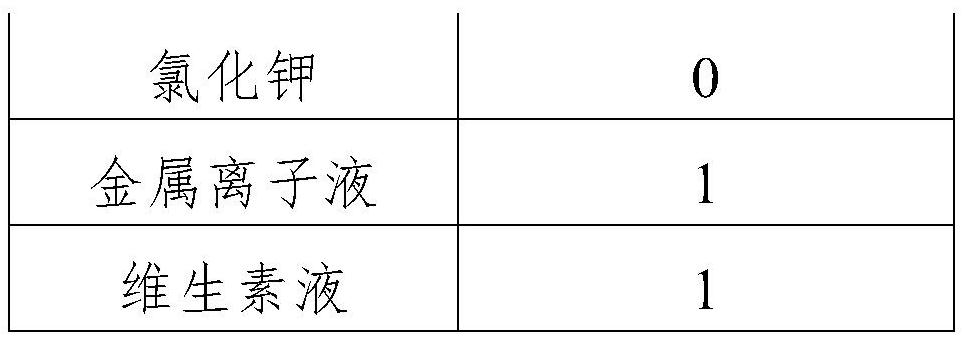

[0040] The method provided in the embodiment of the present invention is the same as that of embodiment 1, and the difference is: 1) in the fermentation system:

[0041] raw material name Fermentation medium (g / L) glycerin 50 Glutamate 45 yeast extract 4 Potassium dihydrogen phosphate 4.2 Magnesium sulfate 10 Sodium chloride 0 calcium chloride 0 Sodium sulfate 0 sodium bicarbonate 0 Ammonium sulfate 2 Potassium chloride 0 metal ionic liquid 2 Vitamin liquid 2

[0042] 2) Step 7 in this embodiment is different from Step 7 in Embodiment 1:

[0043] 7. According to the inoculation amount of 0.2‰, insert the cultured seed bottle seed liquid into the 1700L seed tank containing the above-mentioned 1000L seed tank medium, at the cultivation temperature of 28°C, the stirring speed of 200rpm, the ventilation rate of 1vvm, and the natural cultivation of pH for 24h, to obtain Seed jar. (The see...

Embodiment 3

[0048] The method provided by the embodiment of the present invention is the same as that of embodiment 1, and the difference is: in the fermentation system:

[0049]

[0050]

[0051] Two groups of parallel experiments, shake flask fermentation: sampling and testing, the average of the two batches is that the dry weight of the bacteria is 70g / L, the total oil is 41g / L, the oil content is 58.5%, and the DHA yield is 21g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com