Bismuth-tin-antimony-containing high-entropy oxide negative electrode energy storage material as well as preparation method and application thereof

A technology of energy storage materials and oxides, which is applied in the direction of negative electrodes, active material electrodes, battery electrodes, etc., can solve the problems of unstable cycle performance, poor electrical conductivity, and low capacity, and achieve inhibition of aggregation and crack propagation, electrical conductivity Good, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation method of the high-entropy oxide negative electrode energy storage material containing bismuth, tin and antimony, the steps are as follows:

[0050] The first step: Weigh equimolar amounts of cobalt carbonate, indium acetate, bismuth nitrate, stannous chloride, and antimony acetate according to the molecular formula and put them into the ball milling tank, and set the ball milling speed to 400r min. -1 , the high-entropy oxide precursor was obtained with a ball milling time of 8h;

[0051] The second step: take the high-entropy oxide precursor for annealing in a muffle furnace, and keep it at 500 °C for 10 hours in an air atmosphere;

[0052] The third step: grinding the material annealed in air to obtain bismuth tin antimony cobalt indium high-entropy oxide powder.

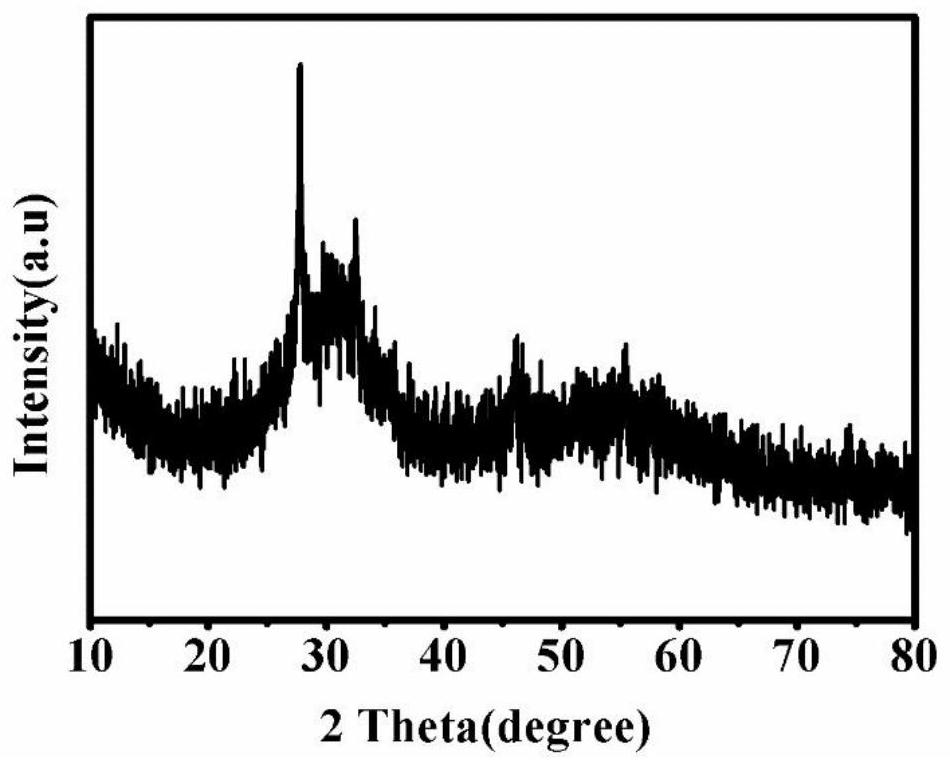

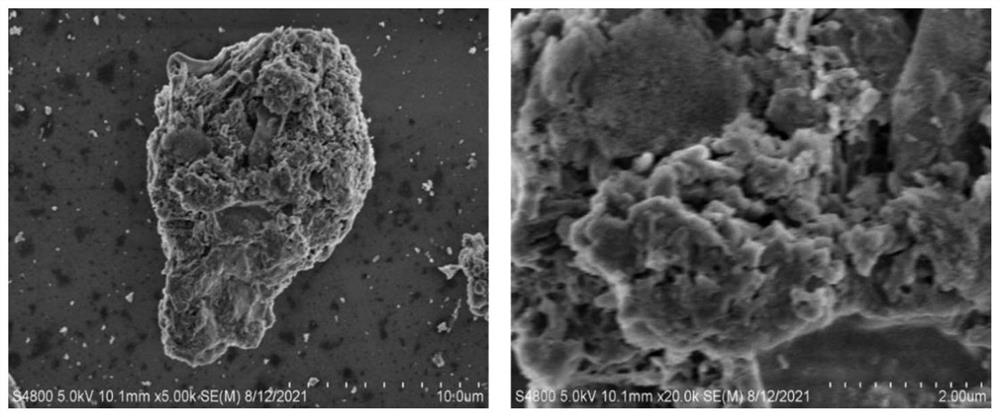

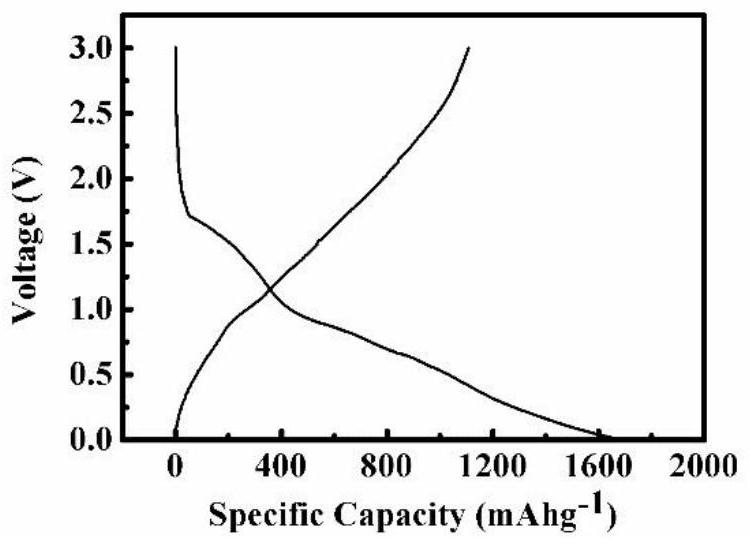

[0053] XRD characterization of bismuth tin antimony cobalt indium pentary high entropy oxide material figure 1 , the microscopic appearance is as figure 2 , it can be seen that the surf...

Embodiment 2

[0062] The preparation method of the high-entropy oxide negative electrode energy storage material containing bismuth, tin and antimony, the steps are as follows:

[0063] The first step: take 0.01mol chromium nitrate, 0.01mol antimony nitrate, 0.02mol bismuth nitrate, 0.02mol copper chloride, 0.02mol tin acetate, 0.02mol ferric nitrate and put them into the ball mill, set the ball milling speed to 500r min -1 , the ball milling time is 12h;

[0064] The second step: take the high-entropy oxide precursor for annealing in a muffle furnace, and keep it at 700 °C for 10 hours in an air atmosphere;

[0065] The third step: grinding the material annealed in air to obtain bismuth tin antimony iron copper chromium hexagonal high entropy oxide powder.

Embodiment 3

[0067] The preparation method of the high-entropy oxide negative electrode energy storage material containing bismuth, tin and antimony, the steps are as follows:

[0068] Step 1: Add 0.015mol cobalt acetate, 0.025mol indium acetate, 0.015mol bismuth nitrate, 0.025mol stannous chloride, and 0.02mol antimony acetate into a centrifuge tube, then add 30mL of ultrapure water, and freeze in liquid nitrogen 0.5h, then put it into the freeze dryer to dry for 48h;

[0069]The second step: take the high-entropy oxide precursor for annealing in a muffle furnace, and keep it at 600 °C for 10 hours in an air atmosphere;

[0070] The third step: grinding the material annealed in air to obtain bismuth tin antimony cobalt indium high-entropy oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Charge specific capacity | aaaaa | aaaaa |

| Charge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com