Preparation and application of down-conversion material of perovskite solar cell

A technology for converting materials and solar cells, which is applied in the fields of nanotechnology, luminescent materials, and circuits for materials and surface science, and can solve the problems of weak fluorescence performance, low carbon content, and application of carbon dots, so as to improve the utilization rate. efficiency, simple preparation process, and the effect of slowing down the degradation of PSC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

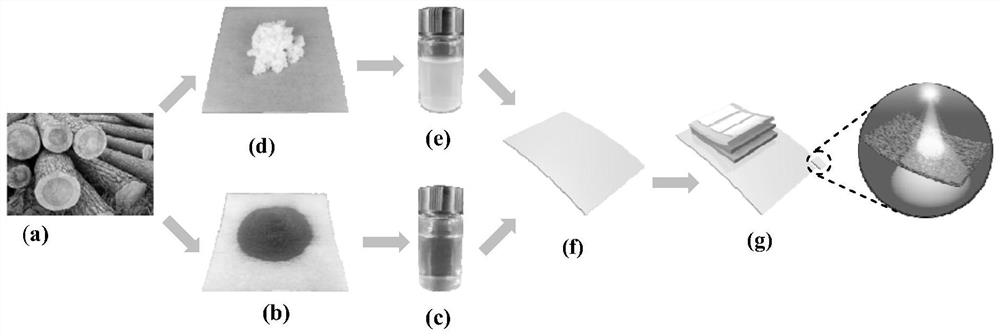

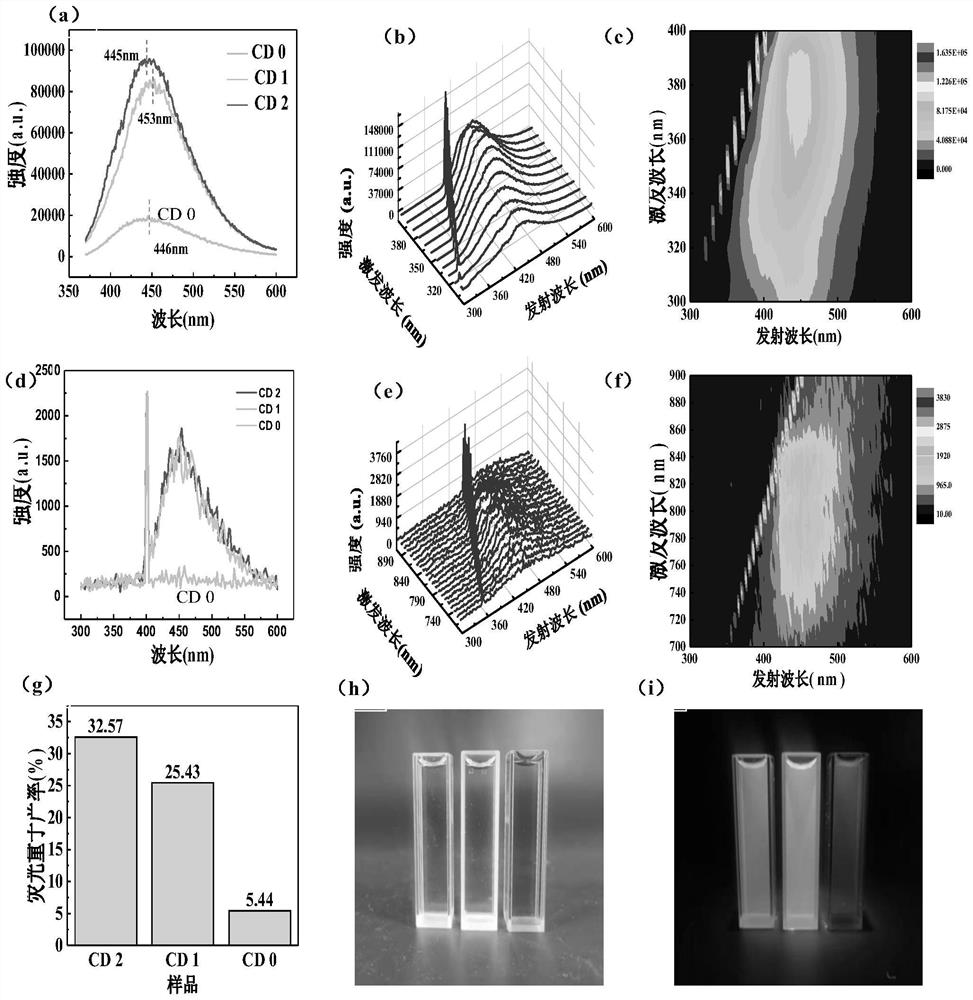

[0050] Example 1: Preparation of CD 2 and PSC devices

[0051] (1) CD 2 preparation

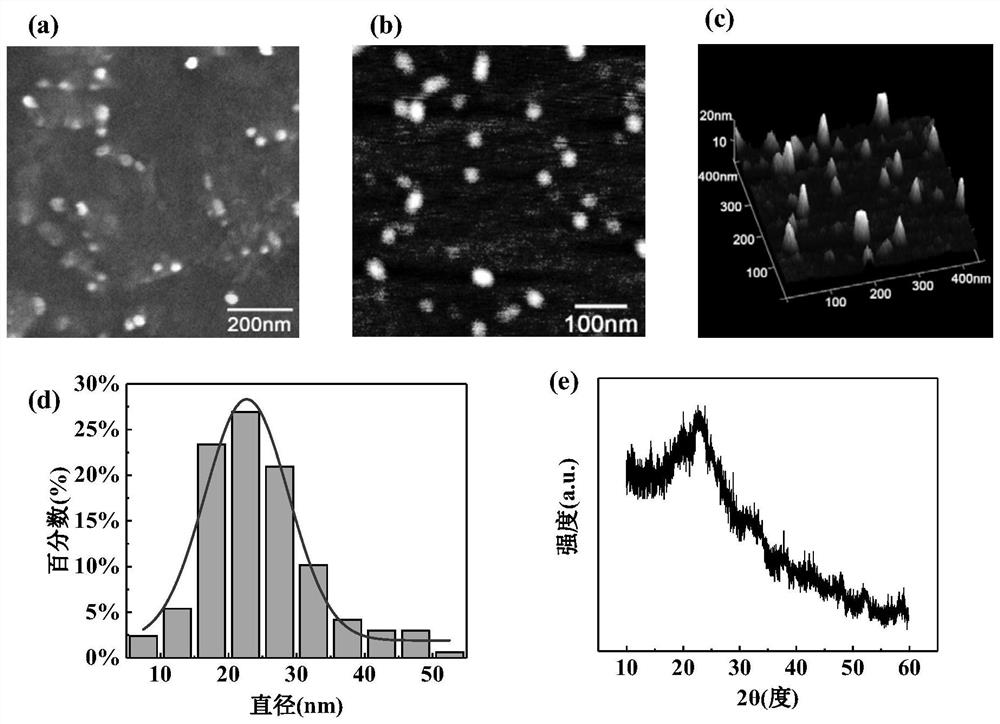

[0052] First, 1 g of lignin was dissolved in 40 mL of deionized water, 6 mL of hydrogen peroxide was added, and the mixture was stirred in a dark environment for 12 hours (25° C.). After that, 10 mL of ammonia water was added to the solution and the mixed solution was transferred to a Teflon-lined autoclave and carbonized at 180 °C for 12 h. After cooling to room temperature, the obtained solution was centrifuged at 12000 rpm for 20 min to remove insoluble large particles and the light brown supernatant was collected, and the solution was filtered with a 0.22 μm nylon membrane syringe filter, the sample obtained at this time was CD 1 . Then 0.5 g of NaBH 4 Added to the solution and stirred at room temperature for 12 h to reduce CD1. Finally the solution was dialyzed for 24h to remove excess NaBH 4 . The obtained reduction was freeze-dried into powder and kept at 4°C until use. This sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com