Preparation method and application of supported TS-1 catalyst

A technology of TS-1 and catalyst, which is applied in the field of preparation of supported TS-1 catalyst, can solve the problems of difficult separation and recovery of TS-1 catalyst, and achieve the effects of reducing the difficulty of loading, increasing stability and facilitating recycling and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041]In the prior art, the preparation methods of the TS-1 catalyst mainly include: spray drying molding method, extrusion molding method, and direct roasting molding method. The spray drying method is to use the principle of spray drying to mix the crystallized TS-1 with the auxiliary agent, and then spray it into the drying chamber in the form of a mist to obtain a microspherical catalyst; the extrusion molding method is to mix water, binder and The TS-1 powder is fully mixed and sent to the extruder. Under the action of external pressure, it is extruded in a cylindrical or other shape; After the alcohol-propylene glycol copolymer is mixed into a slurry, it is directly calcined to obtain a TS-1 catalyst.

[0042] Heterogeneous nucleation principle: There are three forms of nucleation, namely primary homogeneous nucleation, primary heterogeneous nucleation and secondary nucleation. At high supersaturation, the process that the solution spontaneously generates crystal nuclei...

specific Embodiment 1

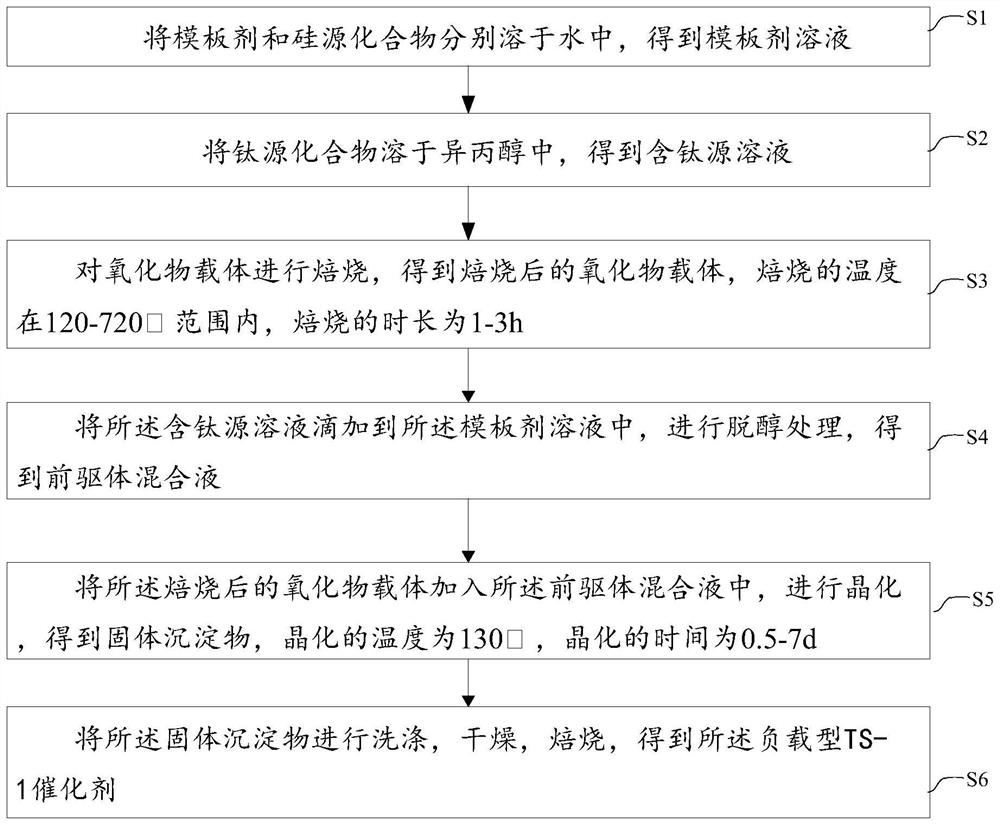

[0044] The embodiment of the present invention provides a preparation method of a supported TS-1 catalyst, figure 1 is a flow chart of the steps of the method, such as figure 1 As shown, the method includes:

[0045] S1: dissolving the templating agent and the silicon source compound in water respectively to obtain a templating agent solution;

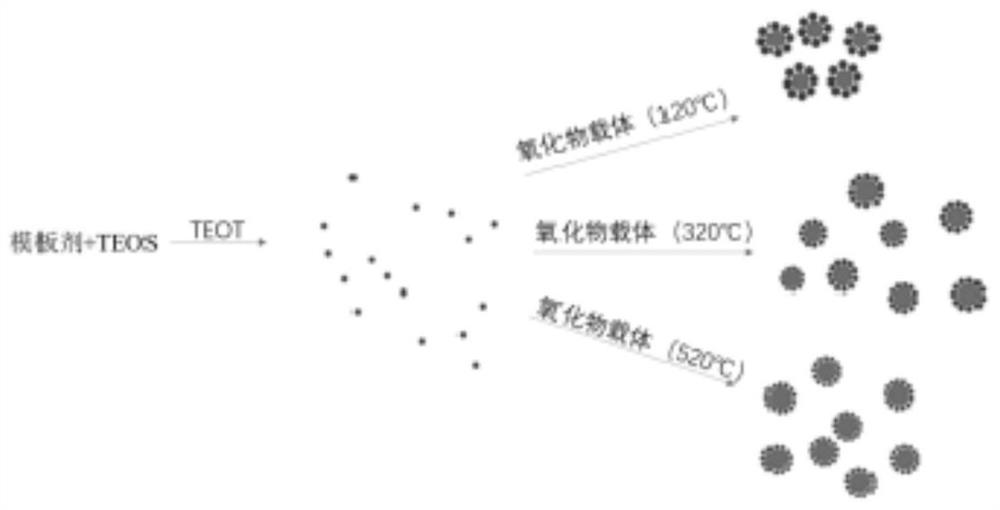

[0046] Dissolve the templating agent and silicon source compound in water and stir vigorously until a clear, homogeneous templating agent solution is formed. The template agent is generally a reagent that plays a structure-oriented role in the preparation process of the molecular sieve catalyst. In the embodiment of the present invention, the template agent is tetrapropyl ammonium hydroxide (TPAOH), tetrapropyl ammonium bromide (TPABr), One or more of n-butylamine and inorganic alkali ammonia water, preferably tetrapropylamine hydroxide (TPAOH). The silicon source compound is tetraethyl silicate (TEOS).

[0047] S2: dissolving the ...

Embodiment approach

[0063] One implementation is:

[0064] Step S4 further includes, S4': adding the precursor mixture into the organic amine solution, and stirring, to obtain the organic amine-treated precursor mixture;

[0065] The step S5 is specifically as follows: adding the calcined oxide carrier into the organic amine-treated precursor mixture, and performing crystallization to obtain the solid precipitate.

[0066] The organic amine solution can be methylamine solution or ethylamine solution, which is not limited in this embodiment. TS-1 molecular sieve and ZSM-5 molecular sieve have the same MFI topology, belong to orthorhombic crystal system, and its skeleton contains two intersecting channel systems. in TS-1. TI atoms enter the molecular sieve framework and are highly dispersed, forming isolated -Si-O-Ti-O-Si- units without the existence of Ti-O-Ti structure. The excellent catalytic oxygen activity of TS-1 molecular sieve is not simply caused by the acidity and alkalinity of the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com