Blocky superfine silver powder and preparation method and application thereof

An ultra-fine silver and block technology, applied in metal processing equipment, conductive materials dispersed in non-conductive inorganic materials, transportation and packaging, etc., can solve the problem of low surface energy, anti-oxidation performance, toxic nitrous acid gas, and complex To achieve the effect of excellent dispersibility, high repeatability, and expansion of reaction scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

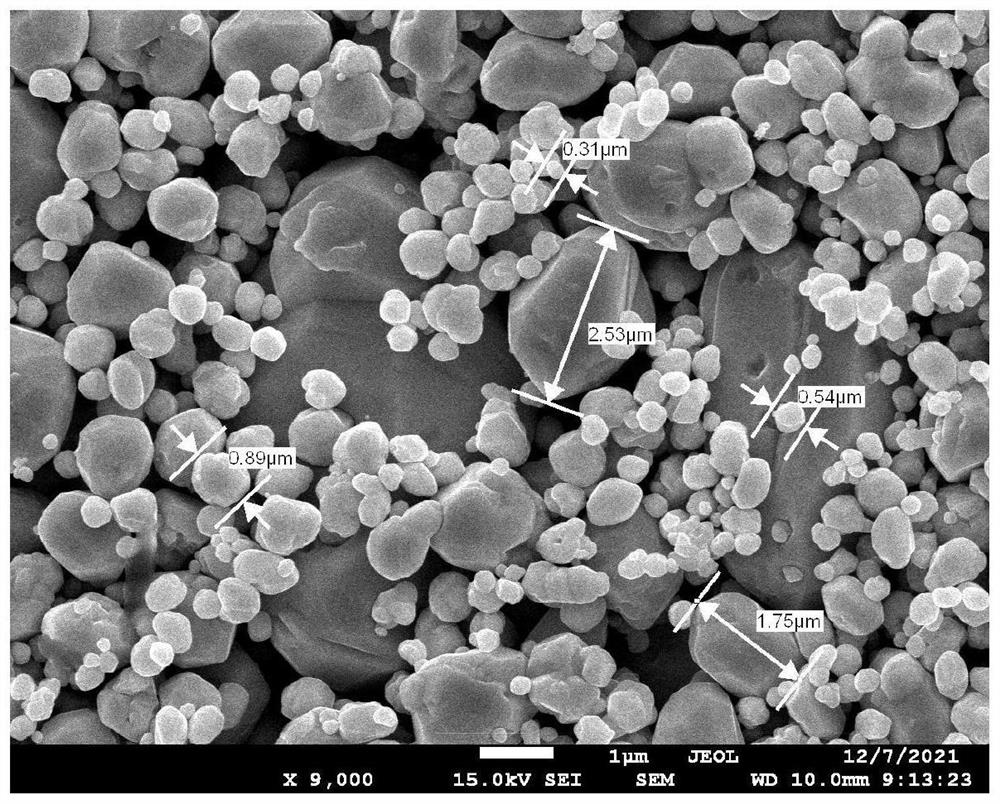

[0057] This embodiment provides a preparation method of massive ultrafine silver powder, the preparation method includes: weighing 21.4 g of silver nitrate, using a mixed solution composed of 280 mL of ethanol and 70 mL of water as a solvent (the volume fraction of ethanol accounts for 80%) to carry out Dissolve, make the concentration of silver nitrate be 61g / L, take by weighing and add the methyl stearate of 1.7g as protective agent, stir and dissolve and then weigh and add the D-ribose of 26.7g as reducing agent, mix and stir at room temperature The solution formed a precursor solution after 30 minutes, wherein the mass ratio of silver nitrate and methyl stearate was 1:0.079, and the mass ratio of silver nitrate and D-ribose was 1:1.25; then the precursor solution was placed in the solution. The reaction kettle was subjected to a chemical reduction reaction at 110 ° C for 10 hours. After the reaction was completed, the reaction kettle was cooled to room temperature with circ...

Embodiment 2

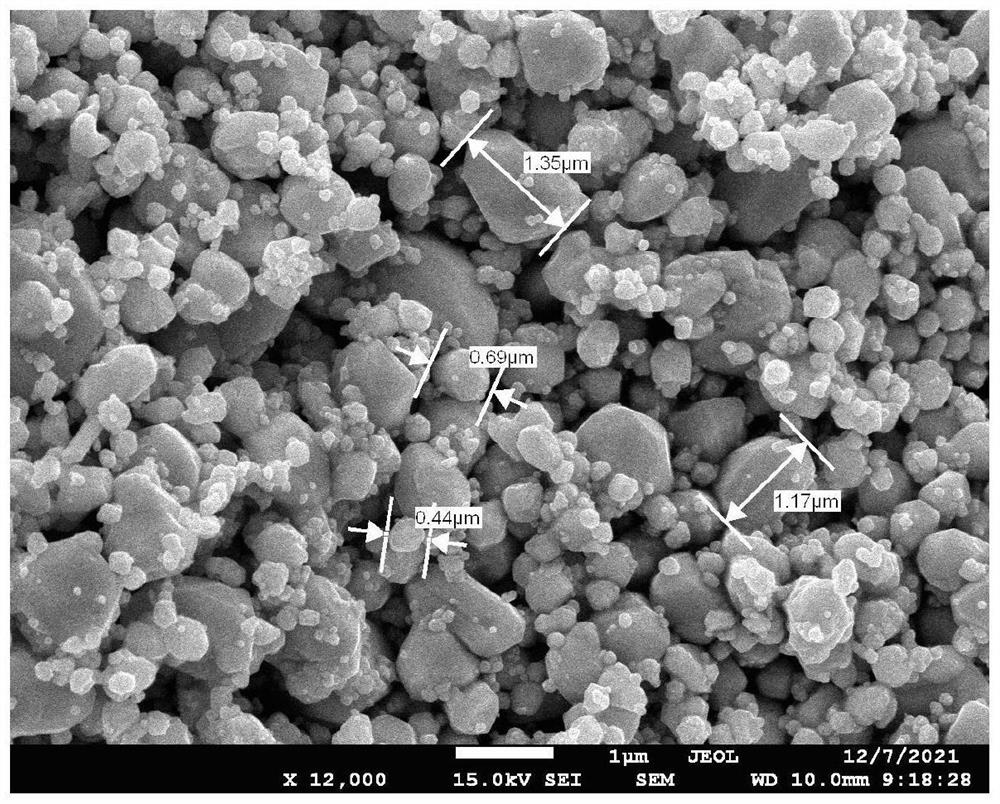

[0059] This embodiment provides a preparation method of massive ultrafine silver powder, the preparation method includes: weighing 35.6 g of silver nitrate, using a mixed solution composed of 245 mL of ethanol and 105 mL of water as a solvent (the volume fraction of ethanol accounts for 70%) to carry out Dissolve, make the concentration of silver nitrate be 102g / L, take by weighing and add the methyl stearate of 2.9g as protective agent, stir and dissolve again take by weighing and add the D-ribose of 47.8g as reducing agent, mix and stir at room temperature After 30 minutes of the solution, a precursor solution was formed, wherein the mass ratio of silver nitrate and methyl stearate was 1:0.082, and the mass ratio of silver nitrate and D-ribose was 1:1.34; the precursor solution was subsequently placed in the solution. The reaction kettle was subjected to a chemical reduction reaction at 110 °C for 10 hours. After the reaction was completed, the reaction kettle was cooled to r...

Embodiment 3

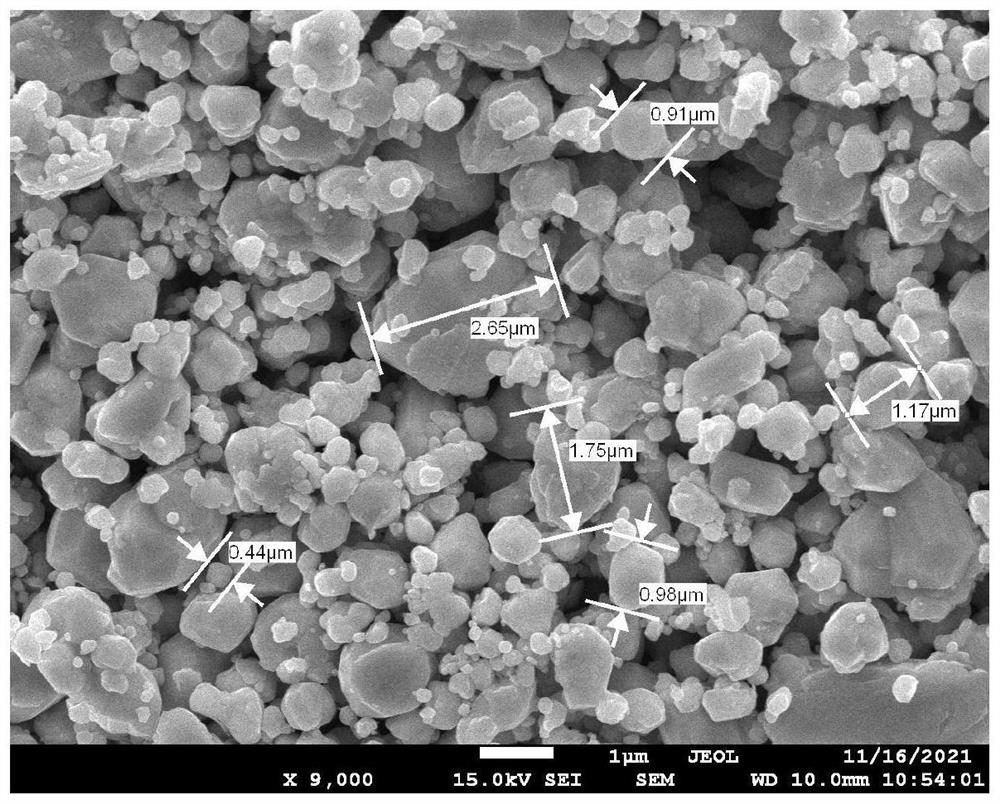

[0061]This embodiment provides a method for preparing massive ultrafine silver powder, the preparation method includes: weighing 142.4 g of silver nitrate, using a mixed solution composed of 1120 mL of ethanol and 280 mL of water as a solvent (the volume fraction of ethanol accounts for 80%) to carry out Dissolve, make the concentration of silver nitrate be 102g / L, take by weighing and add the methyl stearate of 11.4g as protective agent, stir and dissolve and then take by weighing and add the D-ribose of 178g as reducing agent, mix and stir the solution at room temperature After 30 minutes, a precursor solution was formed, wherein the mass ratio of silver nitrate and methyl stearate was 1:0.08, and the mass ratio of silver nitrate and D-ribose was 1:1.25; then the precursor solution was placed in the reaction solution. The autoclave was subjected to chemical reduction reaction at 110°C for 8h. After the reaction was completed, the reaction autoclave was cooled to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com