Titanium dioxide for extinction of chinlon chemical fibers and preparation method of titanium dioxide

A technology of titanium dioxide and composite titanium dioxide, applied in chemical instruments and methods, fibrous fillers, rayon manufacturing and other directions, can solve the problems of inability to obtain titanium dioxide, reduce photocatalytic activity, reduce extinction ability, etc., and achieve favorable extinction performance. and mechanical properties, reduce photocatalytic activity, and improve the effect of long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

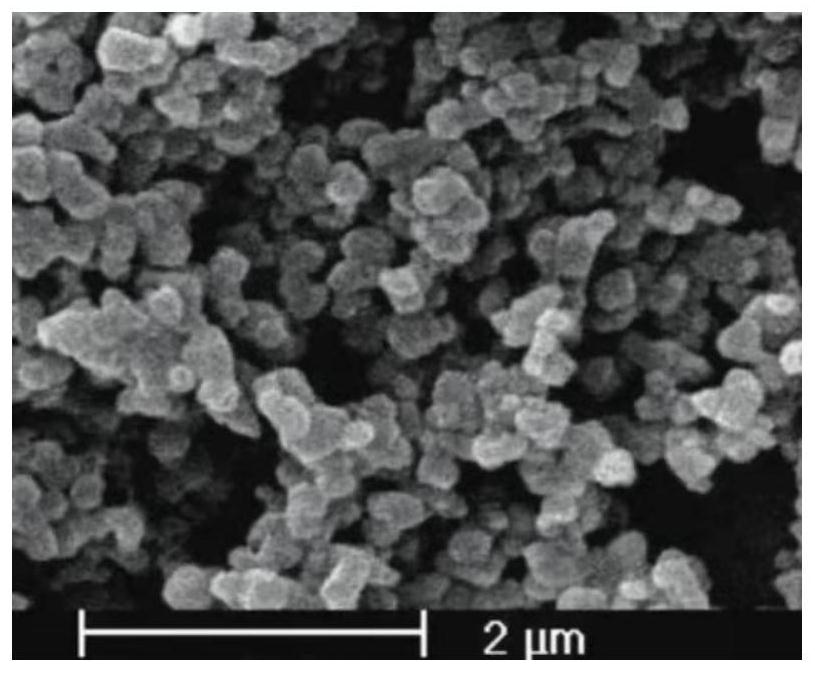

Image

Examples

Embodiment 1

[0075] Preparation of Ultrafine Titanium Dioxide 1

[0076] 1) Under the condition of room temperature and stirring, 0.5kg of 20wt% titanyl sulfate solution was slowly added to 1.5L sodium carbonate solution containing 0.5wt% sodium dodecylbenzenesulfonate, the sodium carbonate concentration was 15wt%, fully stirred 30min; then ultrasonically vibrated for 10min, and after it was fully dispersed, ammonia water was added dropwise with stirring to accelerate the precipitation;

[0077] 2) After the precipitation is complete, add barium chloride solution (the mass consumption of adding barium chloride is 220g), continue stirring for 60min to promote the reaction to precipitate on the surface of titanate particles (form barium carbonate precipitation coating TIO (OH) 2 ) to obtain barium carbonate-coated TIO(OH) 2 the coated particles;

[0078] 3) Filter the precipitate, wash the solid, calcinate at 500°C for 1 hour, add excess dilute hydrochloric acid after cooling, stir for 30m...

Embodiment 1A

[0080] Preparation of Ultrafine Titanium Dioxide 2

[0081] 1) Under room temperature and stirring conditions, 1kg of 25wt% titanium oxynitrate solution was slowly added to the 2L sodium carbonate solution containing 0.3wt% sodium dodecylbenzenesulfonate, the sodium carbonate concentration was 10wt%, and stirred for 60min; then Ultrasonic vibration is carried out to disperse for 15min, and after it is fully dispersed, ammonia water is added dropwise under stirring to accelerate precipitation (keeping pH 9.5-10);

[0082] 2) Add barium chloride solution (the amount of barium chloride is 0.5kg) after the precipitation is complete, continue to stir for 60min to promote the reaction to precipitate on the surface of titanic acid particles, thereby obtaining barium carbonate coated TIO (OH) 2 the coated particles;

[0083] 3) Filter the precipitate, fully wash the solid with deionized water, dry it, then calcinate at 600 °C for 1 h, add excess dilute hydrochloric acid after cooling...

Embodiment 2

[0089] Preparation of Amorphous Silicon Core Aluminum Base Titanium Dioxide

[0090]1) Take 0.1kg of mesoporous silica micropowder (average particle size of about 0.22 microns) and disperse the prepared slurry with deionized water to obtain about 0.5L of slurry, add hydrochloric acid under stirring to adjust pH2; under 40°C water bath and stirring, Slowly add 62ml of titanium tetrachloride; stir at a constant temperature for 90min after the addition, then adjust the pH to 9.5 with sodium hydroxide, and add 100ml of sodium metaaluminate solution dropwise under stirring conditions, which contains about 10g of sodium metaaluminate. Continue to keep stirring for 60 min.

[0091] 2) After the reaction was completed, carbon dioxide was continuously introduced to excess under stirring conditions to fully precipitate aluminum ions until the pH of the solution remained constant and weakly acidic (about 6.5); then the solution was aged for 16 hours at room temperature. After aging, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com