Wood-like black body material and preparation method and application thereof

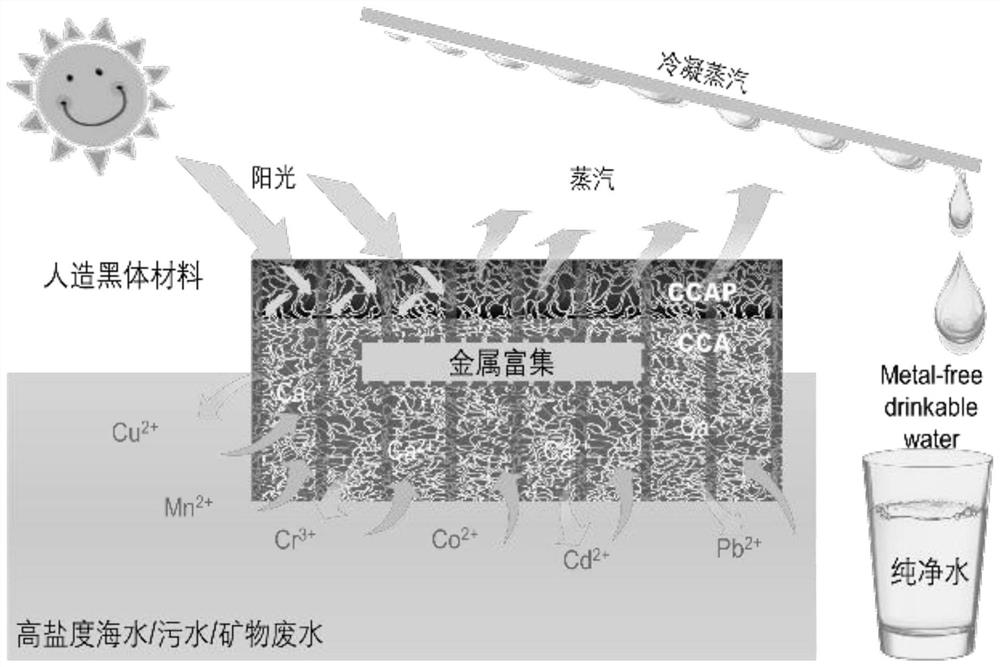

A black body and imitation wood technology, applied in chemical instruments and methods, water/sludge/sewage treatment, seawater treatment, etc., can solve the problems of inapplicable thermal insulation performance, poor hydrophobicity, and affecting the tolerance of carbon-based systems, and achieve The effect of excellent solar absorption capacity, small performance attenuation, and excellent long-term evaporation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

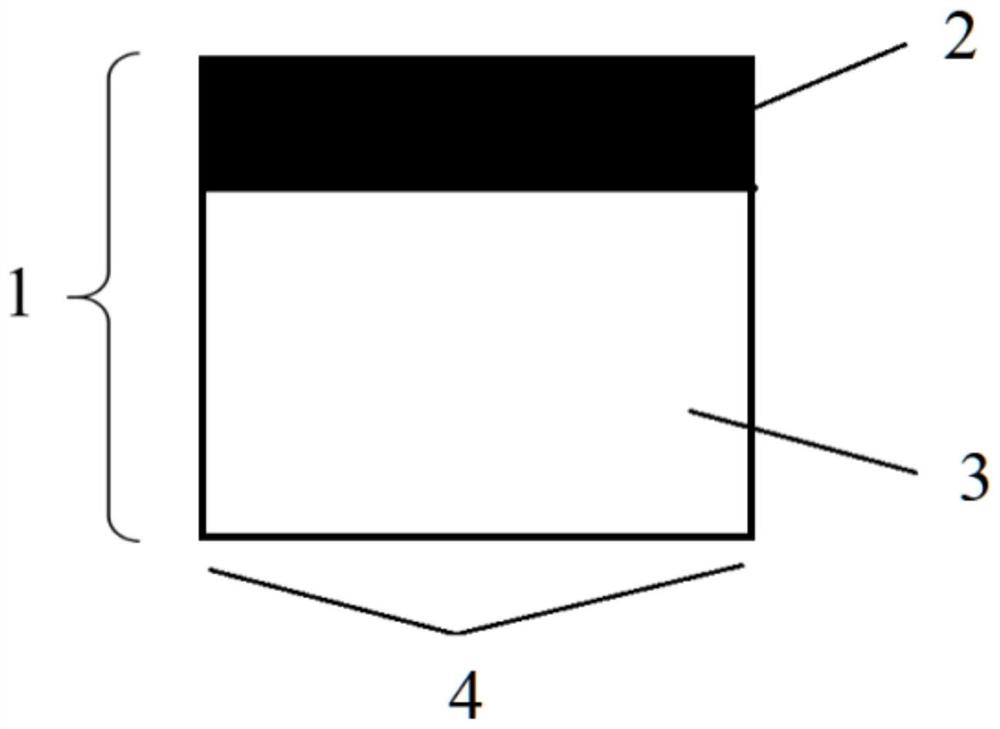

[0046] The invention provides a preparation method of a wood imitation black body material, comprising:

[0047] freezing and casting the mixed solution of carboxymethyl cellulose and sodium alginate to obtain a composite material;

[0048] The mixed solution of sodium alginate and carboxymethyl cellulose, polypyrrole and ammonium persulfate are reacted to obtain a reaction product;

[0049] The reaction product and the composite material are composited and then dried to obtain an intermediate product;

[0050] The intermediate product is calcified to obtain a wood-like black body material.

[0051] The invention provides a method for preparing a wood-like black body material that can be used for metal recovery and enrichment. First, a mixed solution of carboxymethyl cellulose and sodium alginate is frozen and cast on flat copper to prefabricate a wood-like parallel channel structure. ; Then add polypyrrole to the mixed solution of sodium alginate-carboxymethyl cellulose, ox...

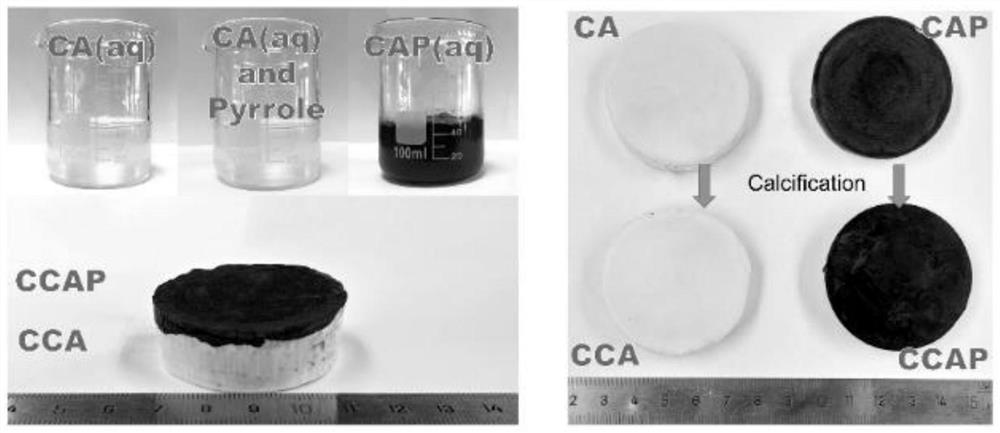

Embodiment 1

[0103] Dissolve 1.0 g of sodium alginate powder and 1.0 g of carboxymethyl cellulose powder in 100 mL of deionized water, stir for 3 h, and then vacuum the solution to remove air bubbles to obtain CA solution. Pour liquid nitrogen into an insulated open container, put in a copper block, immerse the lower part of the copper block in liquid nitrogen, and expose the upper part to the air; take a copper sheet and place a polydimethylsiloxane mold on the upper part, Pour the CA solution of half the volume of the mold and place it on the copper block in liquid nitrogen; after the solution solidifies, a parallel channel structure similar to wood is obtained.

[0104] Take 50 mL of CA solution (the preparation method is the same as above), add 1.5 mL of polypyrrole, and stir for 0.5 h; take 0.4 g of ammonium persulfate and add it to 10 mL of deionized water, add the obtained ammonium persulfate solution to the CA solution, and stir for another 3 h. Until there is no lumpy gel in the s...

Embodiment 2

[0112] Take 2.0 g of sodium alginate powder and 1.0 g of carboxymethyl cellulose powder, dissolve in 100 mL of deionized water, stir for 3 h, and then vacuum the solution to remove air bubbles to obtain CA solution. Pour liquid nitrogen into an insulated open container, put in a copper block, immerse the lower part of the copper block in liquid nitrogen, and expose the upper part to the air; take a copper sheet and place a polydimethylsiloxane mold on the upper part, Pour the CA solution of half the volume of the mold and place it on the copper block in liquid nitrogen; after the solution solidifies, a parallel channel structure similar to wood is obtained.

[0113] Take 50 mL of CA solution (the preparation method is the same as above), add 1.5 mL of polypyrrole, and stir for 0.5 h; take 0.4 g of ammonium persulfate and add it to 10 mL of deionized water, add the obtained ammonium persulfate solution to the CA solution, and stir for another 3 h. Until there is no lumpy gel in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com