Composite nano-enzyme synergistic catalysis fiber material as well as preparation method and application thereof

A technology of synergistic catalysis and fiber materials, applied in dressings for diabetic chronic wound healing, composite nano-enzyme synergistically catalyzed fiber materials and its preparation, and preparation of dressings to promote wound healing, which can solve the problem of high storage conditions of hydrogels and neovascular damage , difficult clinical use and other problems, to achieve the effect of improving the hypoxic microenvironment, preventing infection, and overcoming the difficulty of clinical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

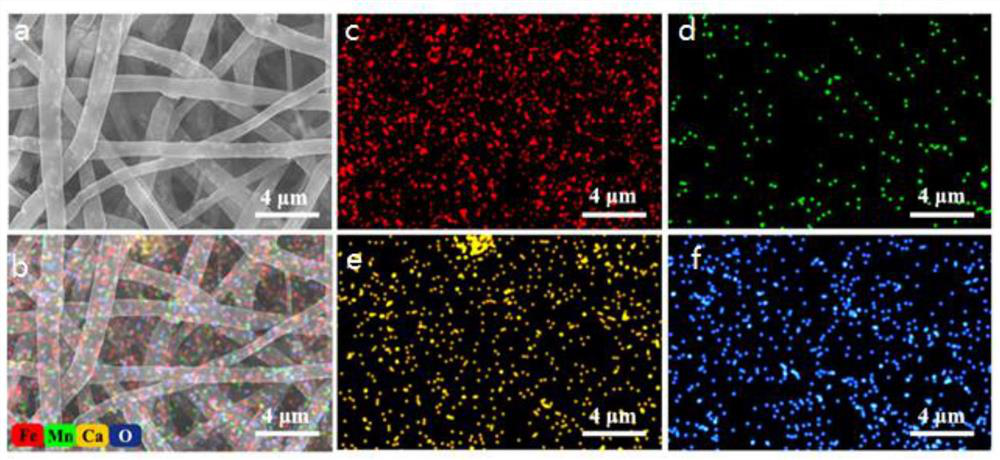

[0056] The present invention also provides a method for preparing the above-mentioned composite nano-enzyme synergistically catalyzing fiber material, the steps are as follows:

[0057] Step 1: Mixing calcium peroxide, manganese dioxide nanozyme, polylactic acid-glycolic acid copolymer and spinning solvent uniformly to obtain spinning solution A;

[0058] Step 2: Mixing calcium peroxide, ferric oxide nanozyme, benzoic acid, polylactic acid-glycolic acid copolymer and spinning solvent uniformly to obtain spinning solution B;

[0059] Step 3: Electrospinning the spinning solution A and the spinning solution B through two parallel nozzles, and drying the product to obtain a composite nano-enzyme synergistic catalytic fiber material.

[0060] In the above technical solution, in step 1 and step 2, the method of mixing is uniform mixing, and the stirring time is 4-6h.

[0061] The present invention also provides the application of the composite nano-enzyme synergistically catalyzin...

Embodiment 1

[0066] Mix 0.1 g of calcium chloride and 0.35 g of polyvinylpyrrolidone in 15 mL of ethanol, ultrasonically treat for 0.5 h, first add 1 mL of ammonia water (0.8 M) to the above solution, continue stirring for 0.5 h, and then add 0.6 mL of hydrogen peroxide (1 M) Add to the above solution at a speed of 0.2 mL / min, continue stirring until a light blue milky solution is obtained, and finally wash with ethanol 3 times and dry at 60 ° C. The obtained product is a monodispersed calcium peroxide sphere with a diameter of 70 nm.

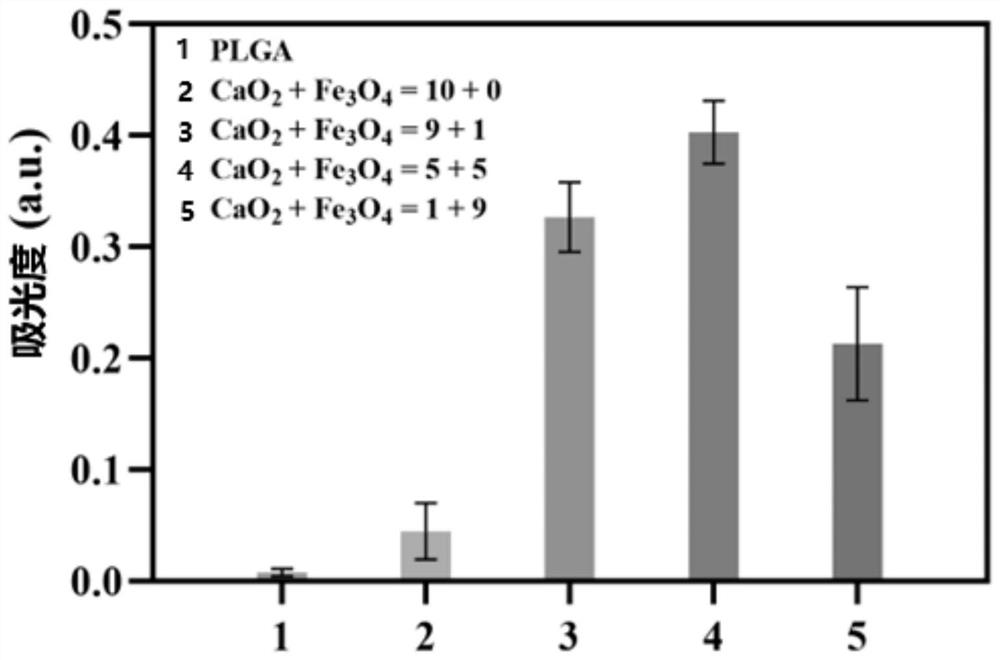

[0067] Dissolve 0.325g of ferric chloride and 0.2g of trisodium citrate in 20mL of ethylene glycol, first add 1.2g of anhydrous sodium acetate to the above solution, stir for 0.5h, and then add the obtained mixed solution into a 50mL reaction kettle, Heating at 200 °C for 10 h, and finally cooling to room temperature, washing with ethanol for 3 times, then washing with deionized water for 3 times, and drying at 60 °C, the obtained black product is a spherica...

Embodiment 2

[0070] Step 1. Dissolve 0.1 PLGA (molar ratio of lactic acid to glycolic acid=50:50, molecular weight is 100000 Da) in 0.89 g of hexafluoroisopropanol to obtain a PLGA solution;

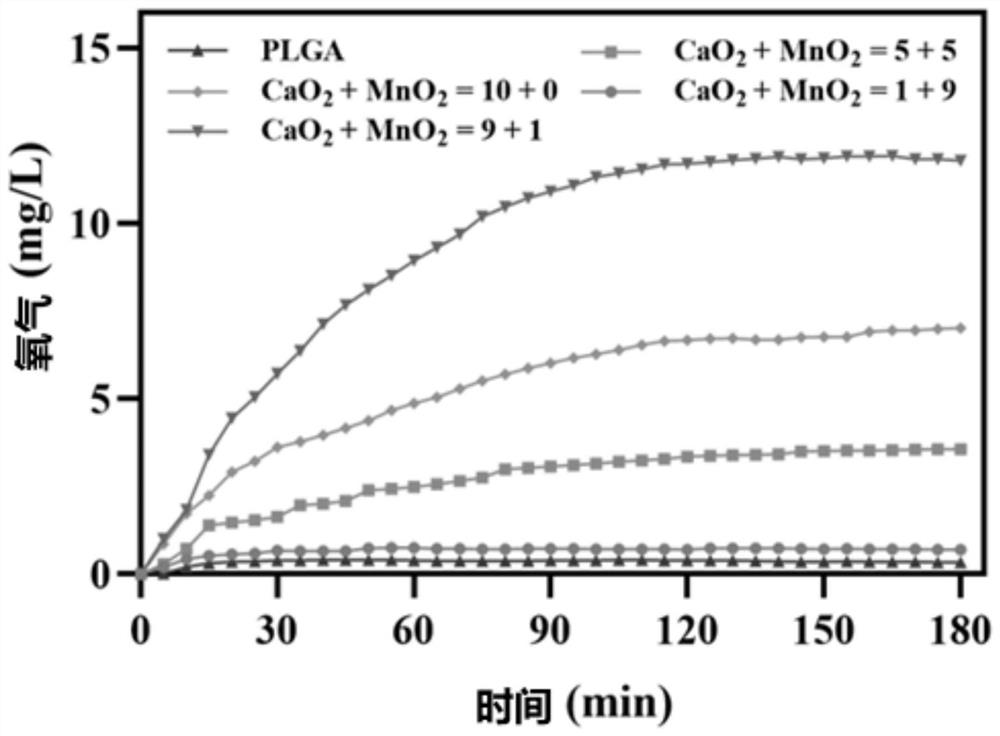

[0071] Step 2. According to the mass ratio of the inner mixture to PLGA of 1:10, mix the inner mixture with the PLGA solution of step 1 to obtain spinning solution A;

[0072] Wherein, the inner admixture is composed of manganese dioxide nanozyme (prepared in Example 1) and calcium peroxide (prepared in Example 1) in mass ratios of 0:10, 1:9, 5:5, and 9:1;

[0073] Step 3: Electrospin the spinning solution A and dry it to prepare a hybrid fiber. The conditions for electrospinning are: a spinning voltage of 20 kV, a perfusion speed of 0.5 mL / h, a receiving distance of 20 cm, and a spinning chamber of 20 cm. The temperature is 25°C; the drying conditions are: temperature 25°C, humidity 20%, time 24h.

[0074] Take 0.08 g of the four types of hybrid fibers prepared in Example 2, respectively, place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com