Water radon-screening emulsion paint

A latex paint, water-based technology, applied in the direction of latex paint, coating, etc., can solve the problems of not paying attention to indoor environmental pollution, easy yellowing and chalking of the paint film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

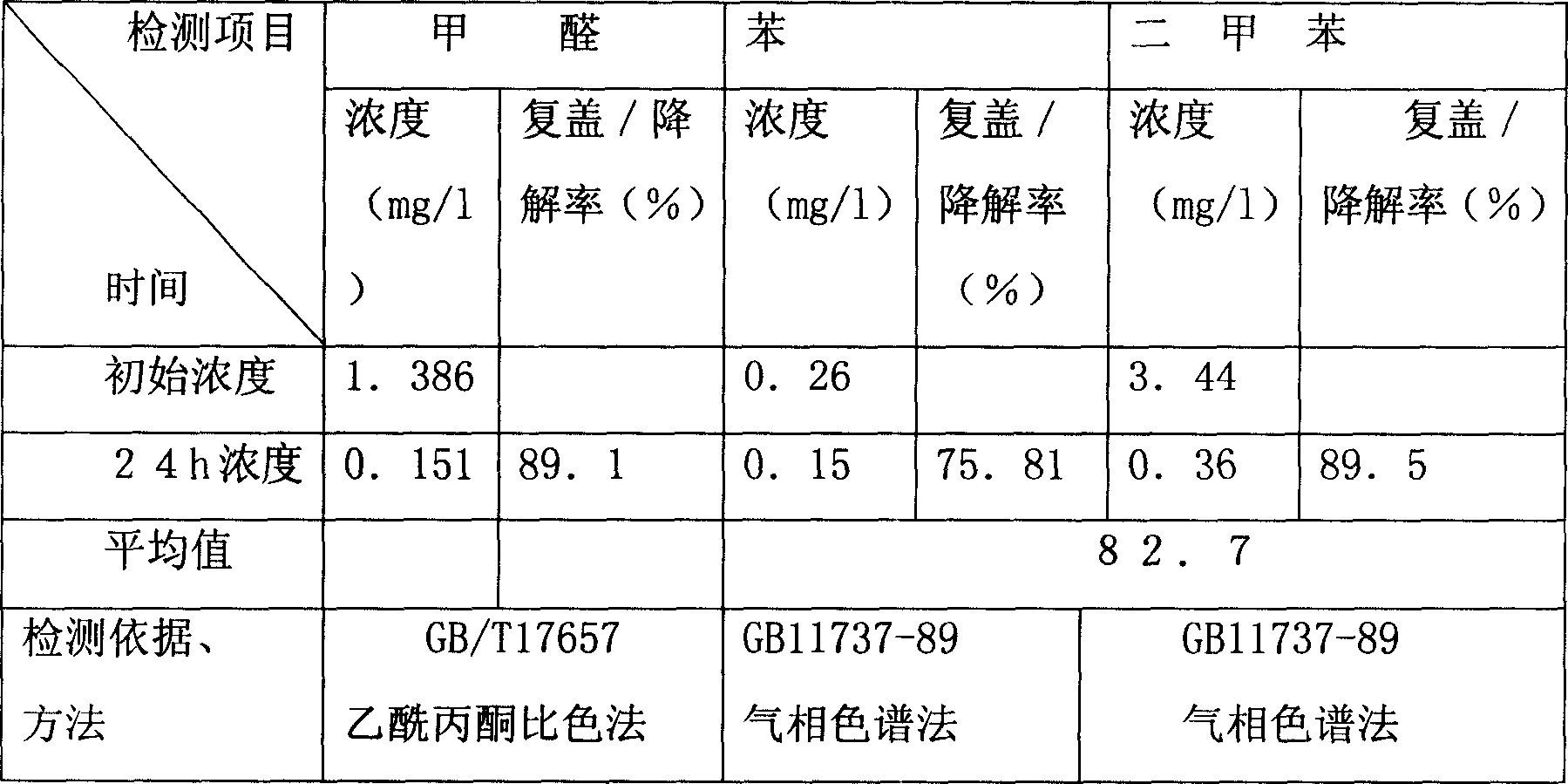

Examples

Embodiment 1

[0105] The equipment and preparation process used in the preparation and detection of embodiment 1 are as follows:

[0106] Instruments and equipment: reaction kettle, high-speed dispersing machine, sand mill, radon measuring instrument, scrub resistance instrument, stirring tank, viscometer, fineness meter, radon exhalation rate standard device, radon exhalation rate measuring instrument, benzene and xylene, formaldehyde Standard device for precipitation rate, chromatograph, etc.;

[0107] Process flow:

[0108] A) The reaction mixing temperature is about 40 degrees;

[0109] B) Put component 1 into the reactor according to the amount first, then gradually add components 2, 3, 4, and 5, and mix and stir for 30 minutes at first slowly and then quickly;

[0110] C) Add components 6, 7, 8, 9, and stir at high speed for 30 minutes;

[0111] D) Add components 10, 11, 12, 13 and stir slowly for 30 minutes;

[0112] E) Take it out and put it into a sand mill to grind for about 6...

Embodiment 2

[0115] Embodiment 2, its component and parts by weight are:

[0116] 1. Water 320

[0117] 2. Hydroxyethyl fiber 2.6

[0118] 3. Dispersant SN-Dispersant-5040 3.2

[0119] 4. Defoamer SN-154 3.5

[0120] 5. Leveling agent NOPCO OSX TM 2000EXP 3

[0121] 6. Light calcium carbonate 125

[0122] 7. Titanium dioxide 175

[0123] 8. Bentonite 45

[0125] 10. Ethylene glycol 6.5

[0126] 11. Film-forming aid dimethyl phthalate 3.5

[0127] 12. PVDF-acrylate copolymer and

[0128] Mixture of vinyl acetate-acrylate copolymer emulsion 375

[0129] 13. GK-98 preservative

[0130] (Trihydroxyethyl-s-triazine) 3.2

[0131] The mixture of the PVDF-acrylate copolymer and vinyl acetate-acrylate copolymer emulsion is that the weight ratio of PVDF-acrylate copolymer and vinyl acetate-acrylate copolymer emulsion is 5:95. become.

[0132] Preparation used equipment and preparation process are as embodiment 1, and the product obtained is white water-based ...

Embodiment 3

[0133] Embodiment 3, its component and parts by weight are as follows:

[0134] 1. Water 310

[0135] 2. Hydroxyethyl Fiber 2.4

[0136] 3. Dispersant SN-Dispersant-5040 and

[0137] Mixture of FC-109 3.1

[0138] 4. Defoamer SN-154 3.2

[0139] 5. Leveling agent NOPCO OSX TM 2000EXP 2.8

[0140] 6. Light calcium carbonate 128

[0141] 7. Titanium dioxide 190

[0142] 8. Bentonite 48

[0144] 10. Ethylene glycol 6.2

[0145] 11. Film-forming aid dimethyl phthalate 3.2

[0146] 12. PVDF-acrylate copolymer and

[0147] Mixture of vinyl acetate-acrylate copolymer emulsion 380

[0148] 13. GK-98 preservative

[0149] (effective chemical component trihydroxyethyl-s-triazine) 2.7

[0150] The mixture of the PVDF-acrylate copolymer and vinyl acetate-acrylate copolymer emulsion is that the weight ratio of PVDF-acrylate copolymer and vinyl acetate-acrylate copolymer emulsion is 5:95. become.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com