Method for preparing rhamnolipid

The technology of rhamnolipid and strain is applied in the field of preparation of rhamnolipid, which can solve the problems of bacterial contamination of culture medium, long screening period, difficulty in judging the production of surfactants, etc., and achieves an obvious effect of environmental remediation. , Improve the screening accuracy, the effect of significant emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

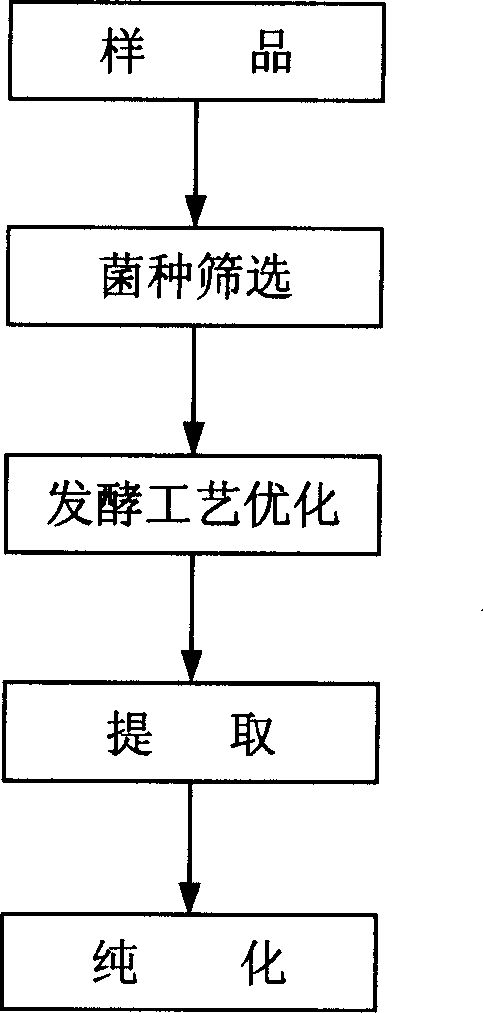

[0016] Embodiment 1: in conjunction with accompanying drawing, the preparation method of rhamnolipid of the present invention, comprises the following steps:

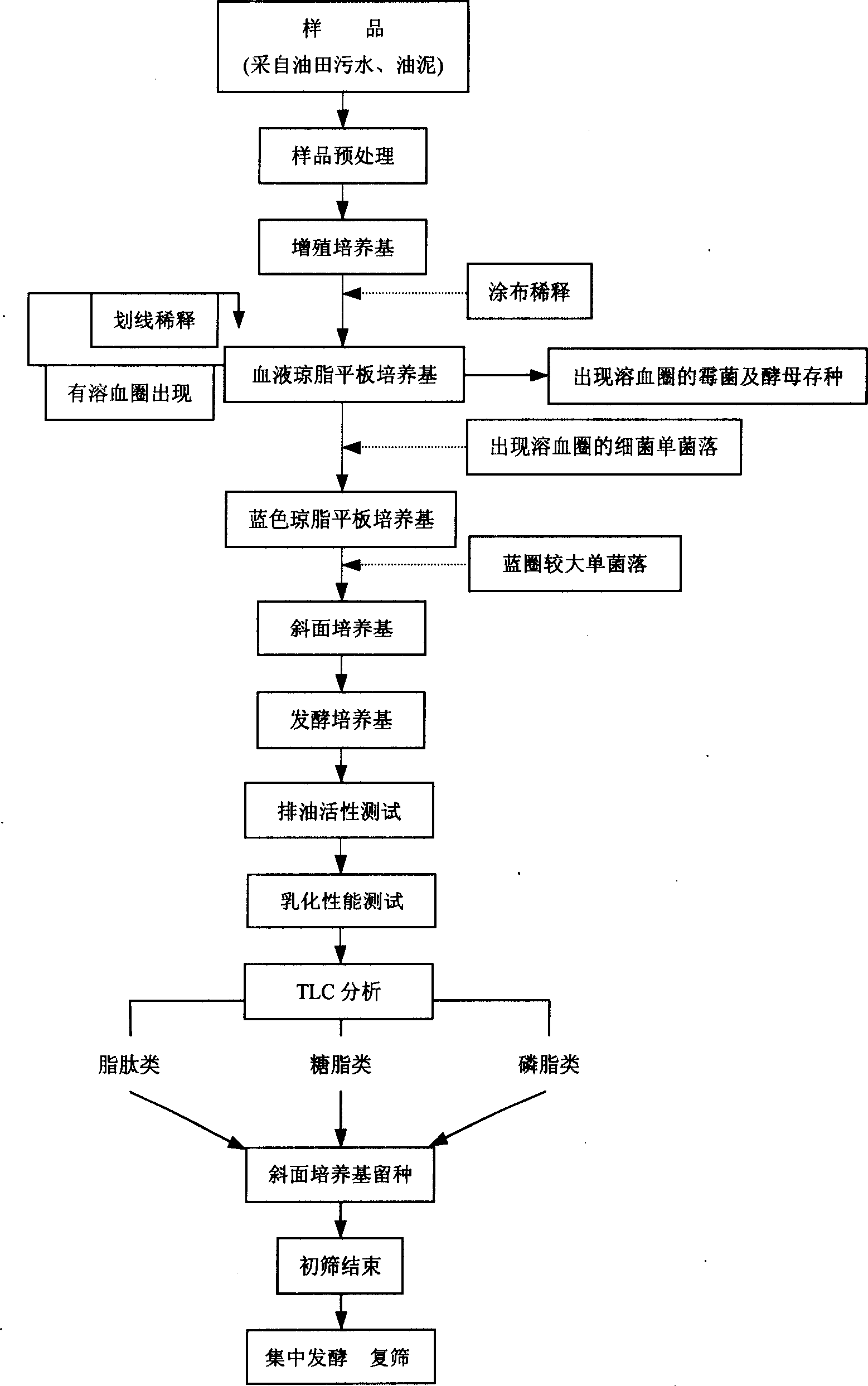

[0017] 1.1 Bacteria screening: The samples from oilfield sewage or oil sludge were soaked and pretreated, and then inserted into the proliferation medium. The cultured culture solution was inoculated on a blood agar plate by streaking and cultured, and a single colony in the hemolysis zone was picked. And inoculated on the blue agar plate for culture, pick the colony with blue halo and insert it into the slant for strain preservation; insert the primary screening strain stored in the slant medium into the fermentation medium and measure its oil discharge after fermentation Activity, emulsifying performance and surface tension of fermentation broth, and then select the target strain and co-exist; that is, select samples from oilfield sewage or oil sludge, soak them in sterile water for 2 hours for pretreatment, take out t...

Embodiment 2

[0029] Example 2: The preparation method of the rhamnolipid of the present invention, sampling from oil pollution in the oil field, and screening through enrichment culture, blood plate (primary screening) and blue gel plate composite screening mode (rescreening) to obtain biosurfactants Produced bacteria, and improved by ultraviolet mutation breeding, the obtained excellent strains were preserved in the PDA slant. Culture by fermentation, i.e. fermentation medium: liquid paraffin or glucose or soybean oil or diesel oil or glycerol 15-35mL, (NH 4 ) 2 SO 4 2-2.5g, Na2HPO 4 ·2H 2 O3-3.8g, KH 2 PO 4 1g, MgSO 4 ·7H 2 O 0.5g, CaCl 2 ·2H 2 O 0.005g, dilute to 1L with deionized water, and adjust pH to 7.5-8. Culture conditions: temperature: 26~36℃, shaker speed: 14~240r / min; volume of conical flask: 50-100mL; seed culture time: 21h; inoculation volume: 5~10%; culture time: 48~158h , the fermentation broth was extracted with chloroform and methanol, and the initial produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com