Electrode array device having an adsorbed porous reaction layer having a linker moiety

a technology of porous reaction layer and electrode array, which is applied in the direction of sequential/parallax process reactions, microorganism testing/measurement, biological apparatus and processes, etc., can solve the problems of acidic reagents that cannot travel away from electrodes, oligo quality problems, and ph decreases, so as to improve synthesis quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiments

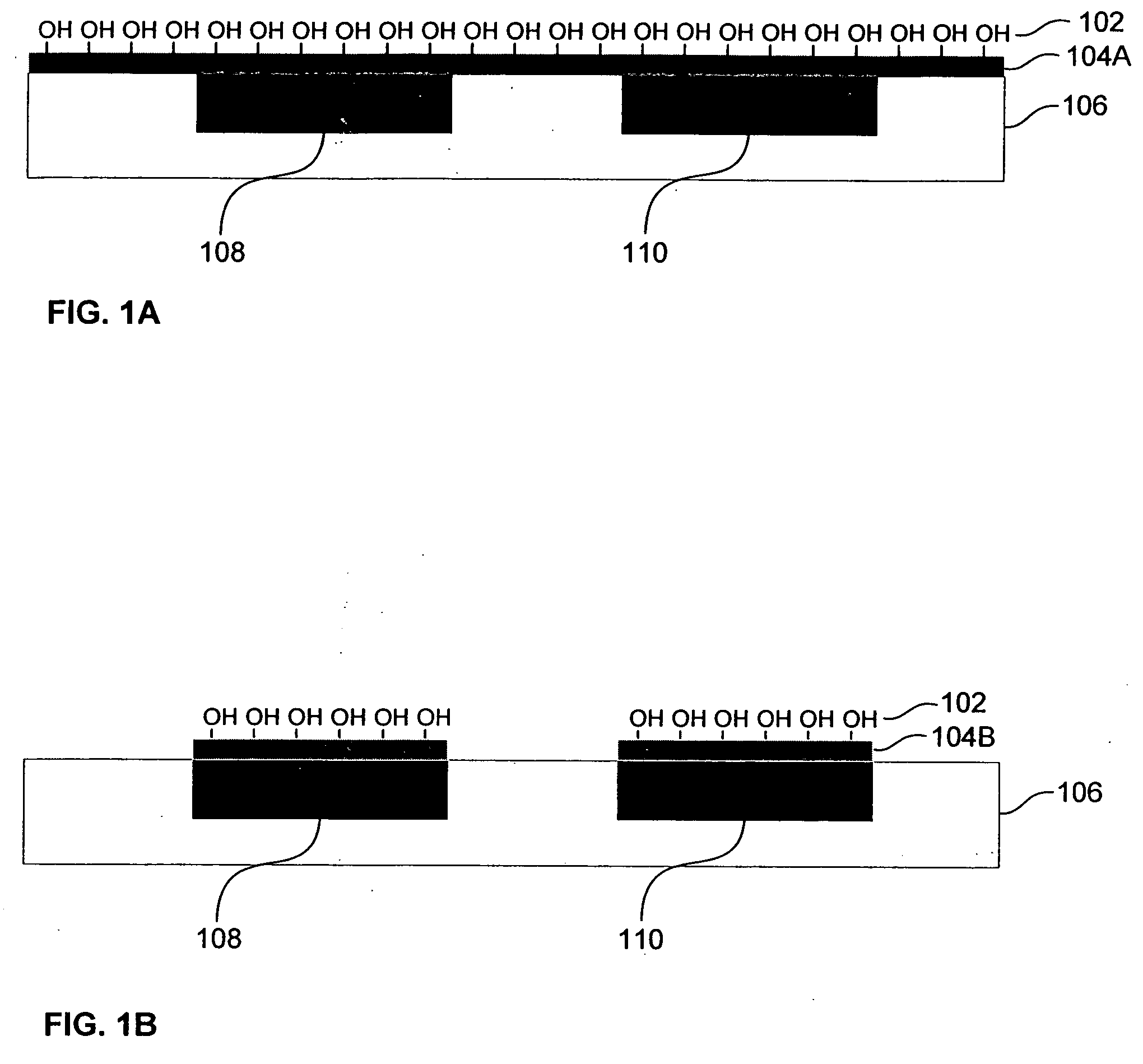

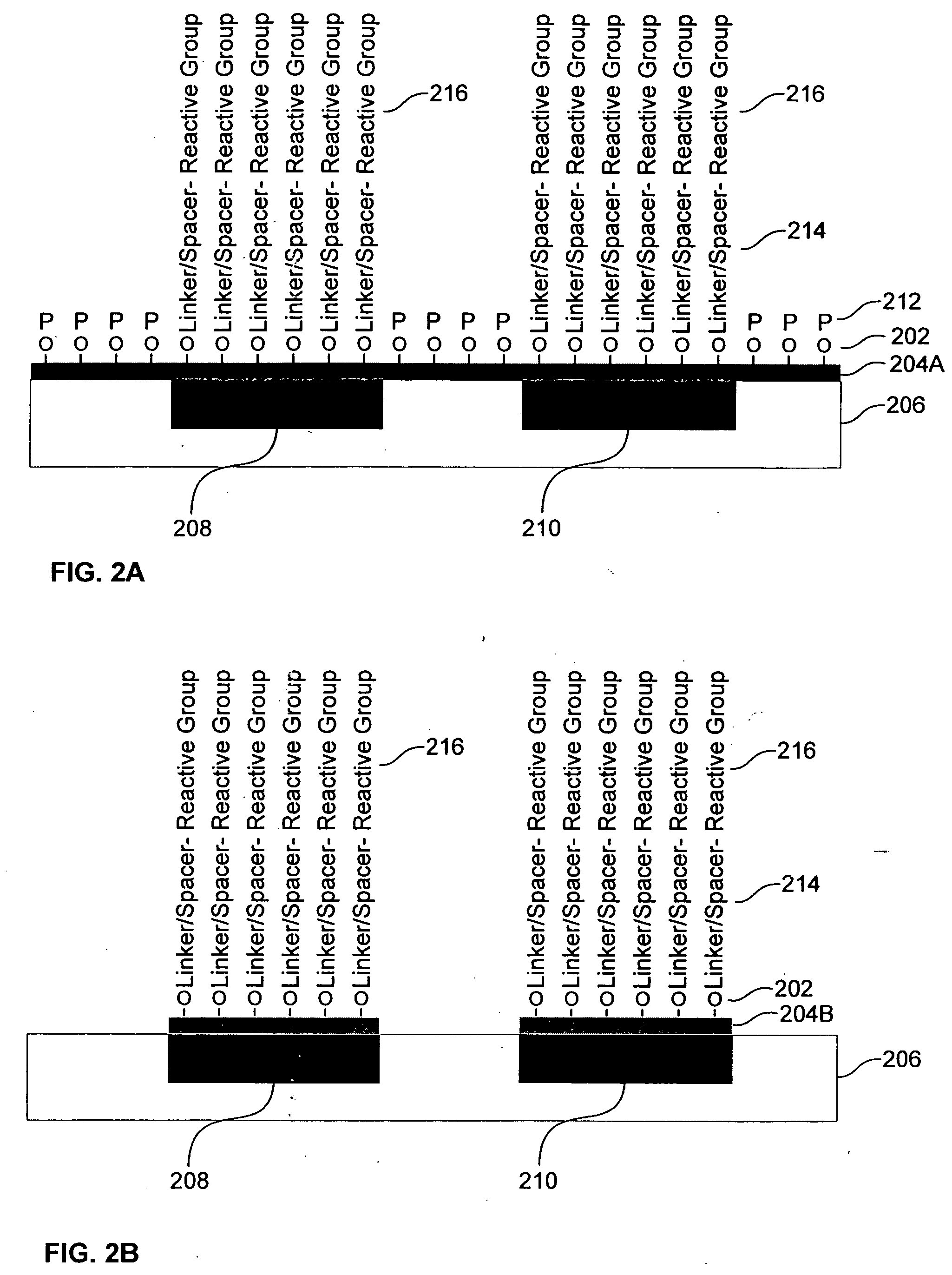

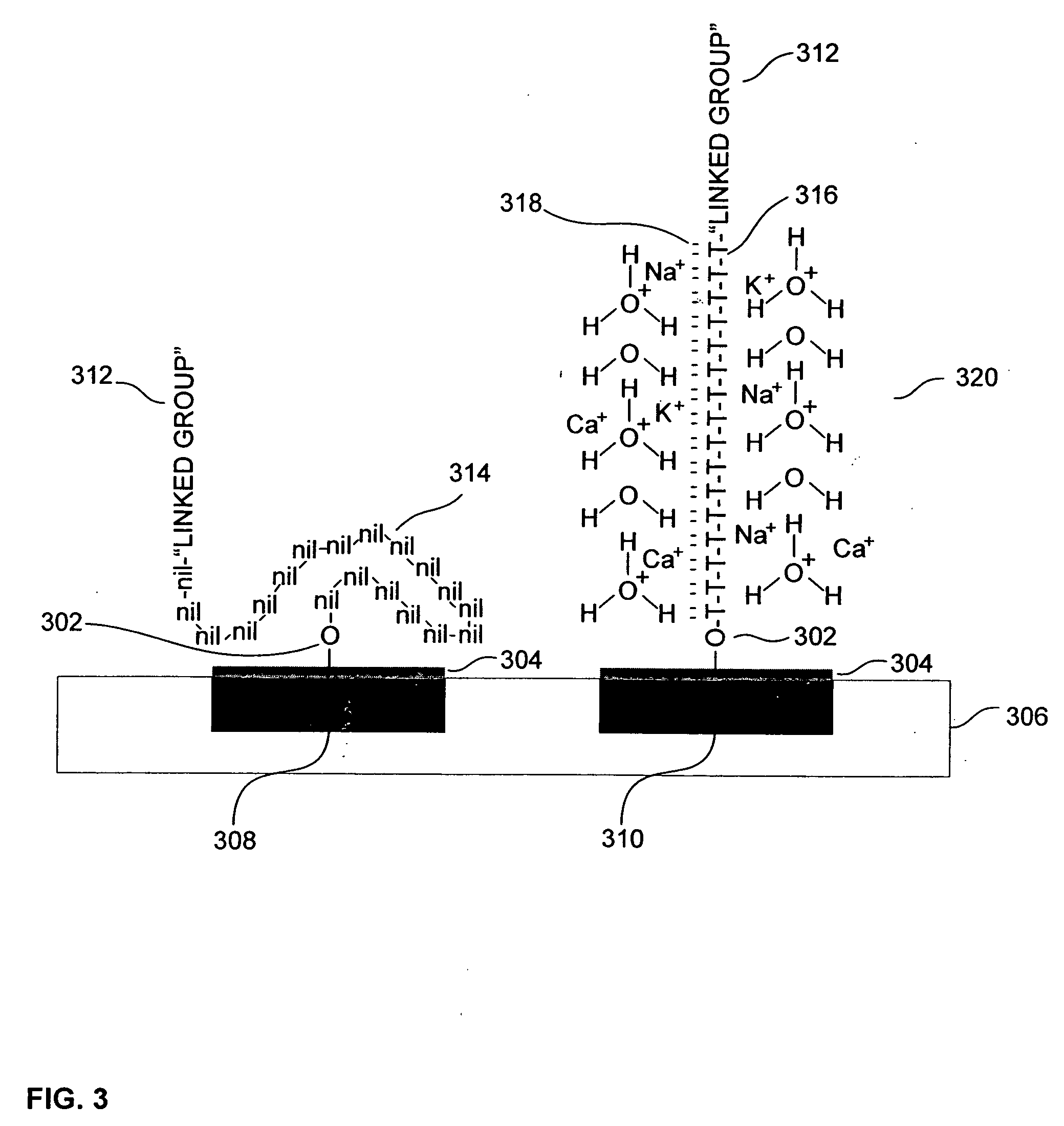

[0146] In an embodiment of the present invention, an electrode microarray having an adsorbed porous reaction layer for improved synthesis quality is provided. The microarray has a plurality of electrodes attached to a substrate, wherein the electrodes are electronically connected to a computer control system that allows selection of any electrode individually or more than one electrode as group of electrodes. FIGS. 1A and 1B are schematics of a cross section of two electrodes 108, 110 of such a microarray 106 having a plurality of electrodes. In one embodiment of the present invention, an adsorbed layer 104A shown in FIG. 1A covers the electrodes and the substrate that the electrodes are attached thereto. The adsorbed layer 104A has hydroxyl reactive groups 102. The reactive groups 102 can be groups other than hydroxyl including but not limited to amine, carboxylic acid, aldehyde, thiol, alkene, alkyne, nitrile, azido, or phosphorous-based compound. In another embodiment shown in FI...

example 1

[0170] This example illustrates microarrays of nucleotides prepared using selected adsorbed porous reaction layers on the different microarrays. Each microarray was cleaned using the plasma cleaning method and the electrochemical cleaning method or using the plasma cleaning method and the hydrogen peroxide cleaning method, each as disclosed herein. After cleaning, each microarray was exposed to a solution containing a chemical for forming an adsorbed porous reaction layer as disclosed herein. The chemicals used for the experiments included agarose, sucrose, diethylene glycol, ethylene glycol, N-hydroxysuccinimide, triethylene glycol, raffinose, melizitose, Splenda®, inulin, polyethylene glycol having a molecular weight of 8000, salicin, ribose, and melibiose.

[0171] After each microarray w prepared having a porous reaction layer, different nucleotides of either 15 mer, shown in FIGS. 11 though 19, 25, and 26, or 35 mer, shown in FIGS. 5 through 10, were synthesized in situ on each m...

example 2

[0180] This example illustrates a peptide array with and without a combination linker and spacer that was synthesized on an electrode microarray of platinum electrodes having an absorbed porous reaction layer comprising sucrose. The combination linker and spacer was a 16 T unit synthesized in situ. After synthesis of the combination linker and spacer, the peptide array was synthesized in situ thereon. Fluorescent reagent was used to image the peptides, but the only image that could be seen was on the electrodes having the combination linker and spacer.

[0181] The electrode microarray used was a commercial microarray made by CombiMatrix Corporation (CUSTOMARRAY) (Dill et al., Anal. Chim. Acta 2001, 444:69, and Montgomery I, II, and III). The microarray consisted of a semiconductor silicon chip with an array of 1024 individually serially addressable 92-micrometer diameter platinum electrodes in a 16×64 pattern. Prior to using the microarray, the electrodes were coated with sucrose to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com