Materials for magnetizing cells and magnetic manipulation

a technology of magnetizing cells and materials, applied in the field of materials, can solve the problems of inability to return to the native state of cells, inability to re-inject cells, and inability to achieve the effect of reversible process, and achieve the effect of promoting rapid cell-cell interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

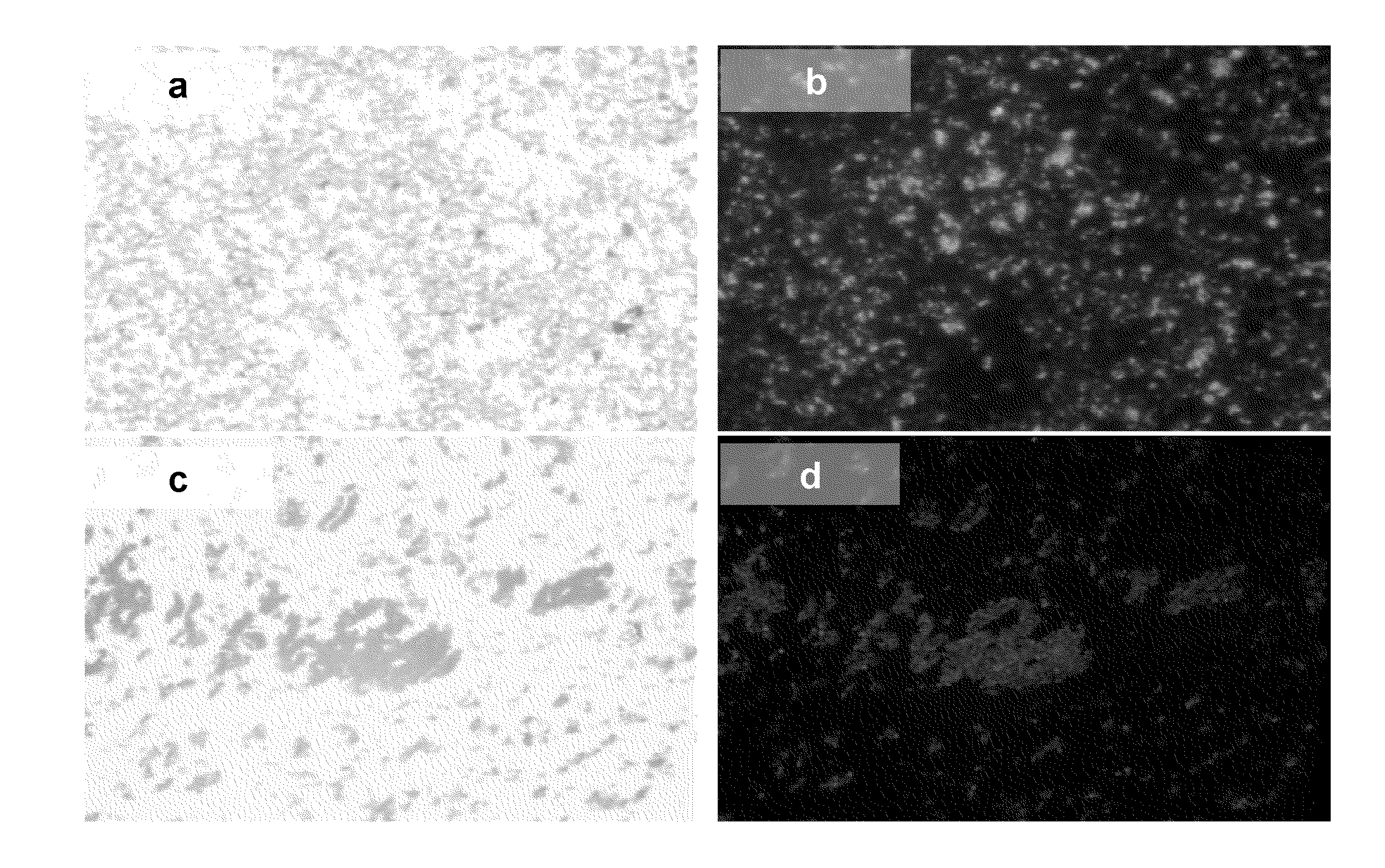

Image

Examples

example 1

Magnetic Nanoparticle Assemblies

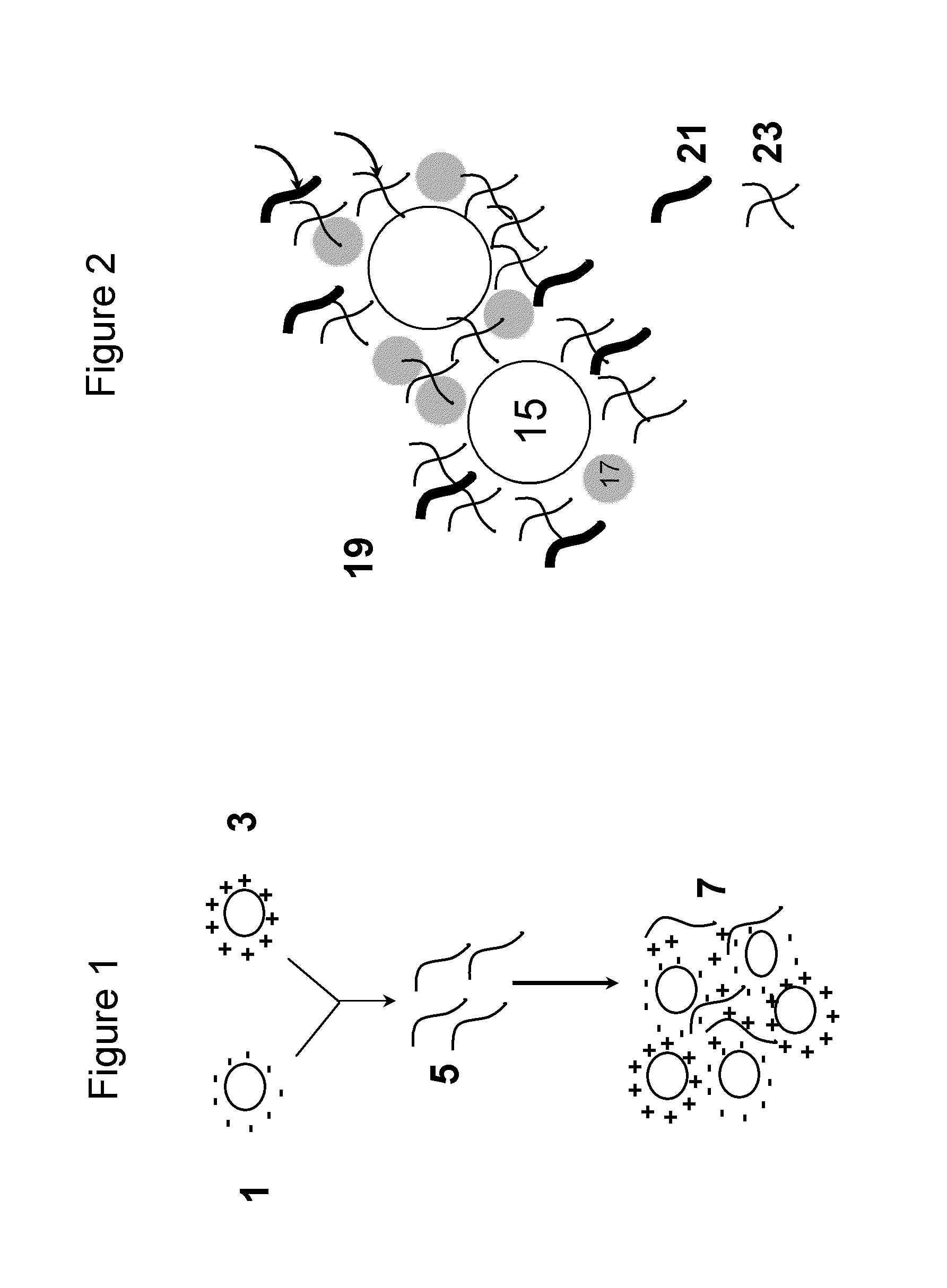

[0052]FIG. 1 shows a general scheme for preparing magnetic nanoparticle assemblies (7) by combining negative nanoparticles (1) and positive nanoparticles (3) (at least one nanoparticle being of magnetic nature) and support molecules (5).

[0053]Solutions of nanoparticles are prepared by separately mixing the nanoparticles in water or low ionic strength buffer (salt concentration <10 mM) at a desired pH. The particle surface charge can be adjusted by choosing the appropriate pH, where low pH buffer (such as citrate or carbonate buffer) can generally increase the overall charge on the nanoparticles. In contrast, high pH buffer (such as borate buffer) can generally decrease the overall charge on the particles. Ideally, the pH of choice for each solution should result in opposite charges between the two particles. This can be achieved because nanoparticles of different composition usually have distinct isoelectric points.

[0054]For example, Au nanoparticles ...

example

Surface Contact

[0094]In the above embodiments we mixed the magnetic nanoparticle assembly with the cells, thus providing an intimate admixture of the components. However, we have also shown that this is not necessary, and that merely being adjacent the magnetic nanoparticle assembly the cells will take up the magnetic nanoparticles. This is of benefit when the cells are needed to be free of magnetic nanoparticle assembly materials.

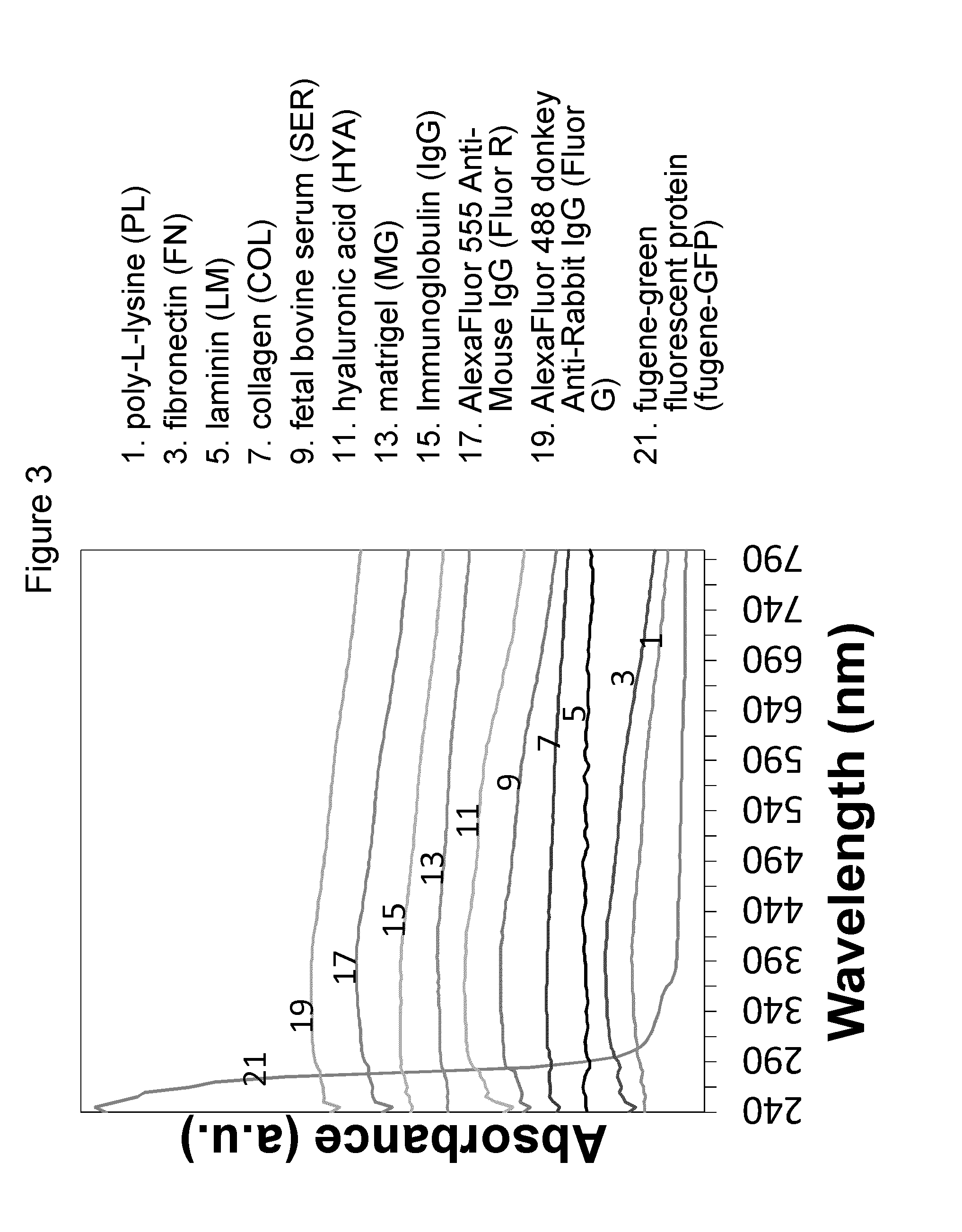

[0095]FIG. 12 illustrates the method whereby magnetic nanoparticle assembly (200) is exposed to a magnetic field. This has the effect of concentrating or compressing the magnetic nanoparticle assembly into a denser magnetic film. Cells (400) can be added above the film, and will naturally settle by gravity onto the film, and their proximity to the film will allow the cells to be magnetized. Then the cells can easily be levitated and separated from the film, levitated and grown in 3D culture. We have tested this concept with a wide variety of support molecu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com