Production and application of an aircraft spreadable, cyanobacterial based biological soil crust inoculant for soil fertilization, soil stablization and atmospheric CO2 drawdown and sequestration

a technology of biological soil crust and fertilizer, applied in algae products, biochemistry instruments, enzymes, etc., can solve the problems of natural restoration, affecting global weather conditions, and taking decades or centuries to build up atmospheric carbon dioxide, etc., to achieve high weight density, facilitate manufacturing of terraderm pellets, and reduce the effect of carbon dioxide build-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

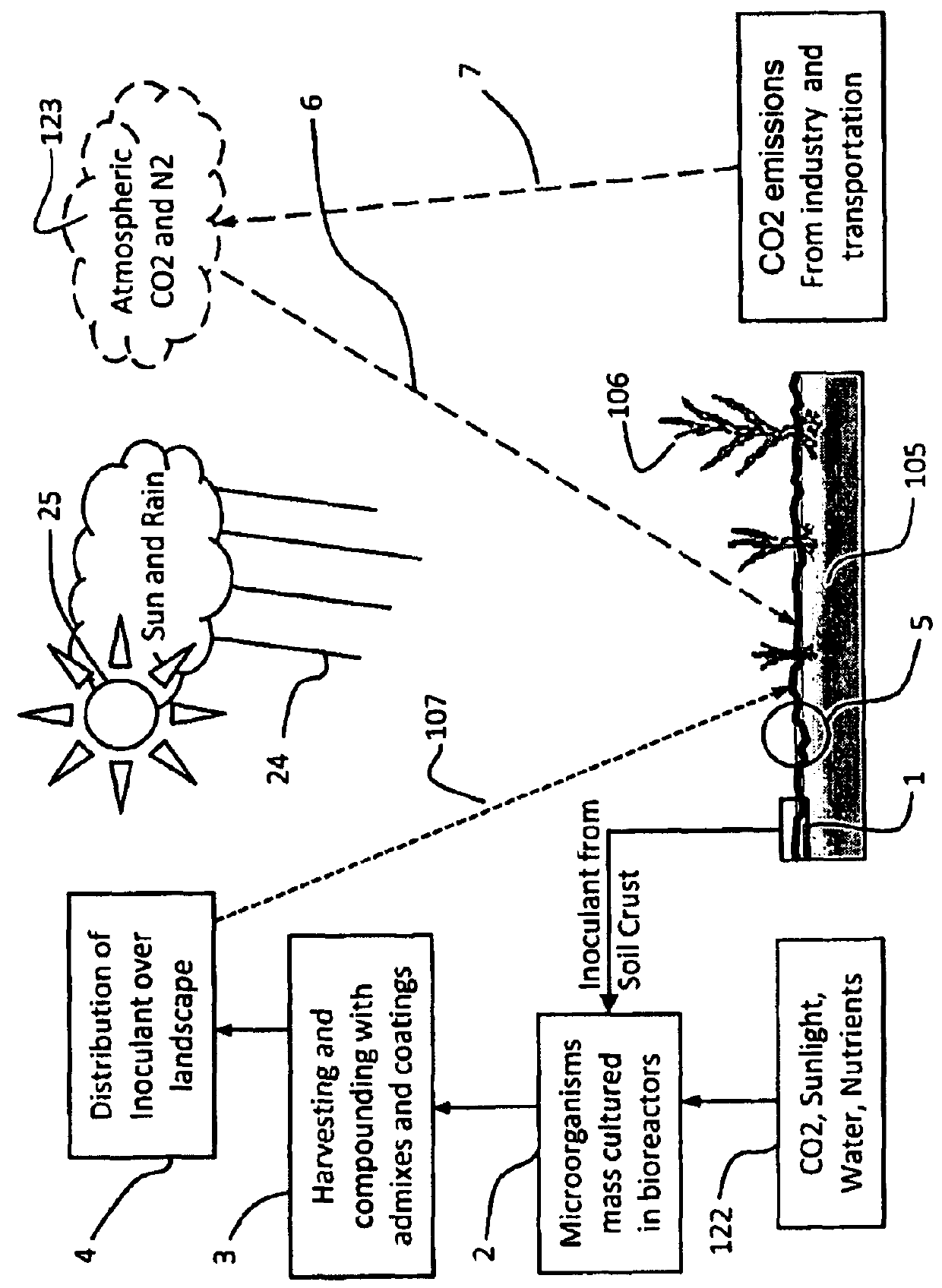

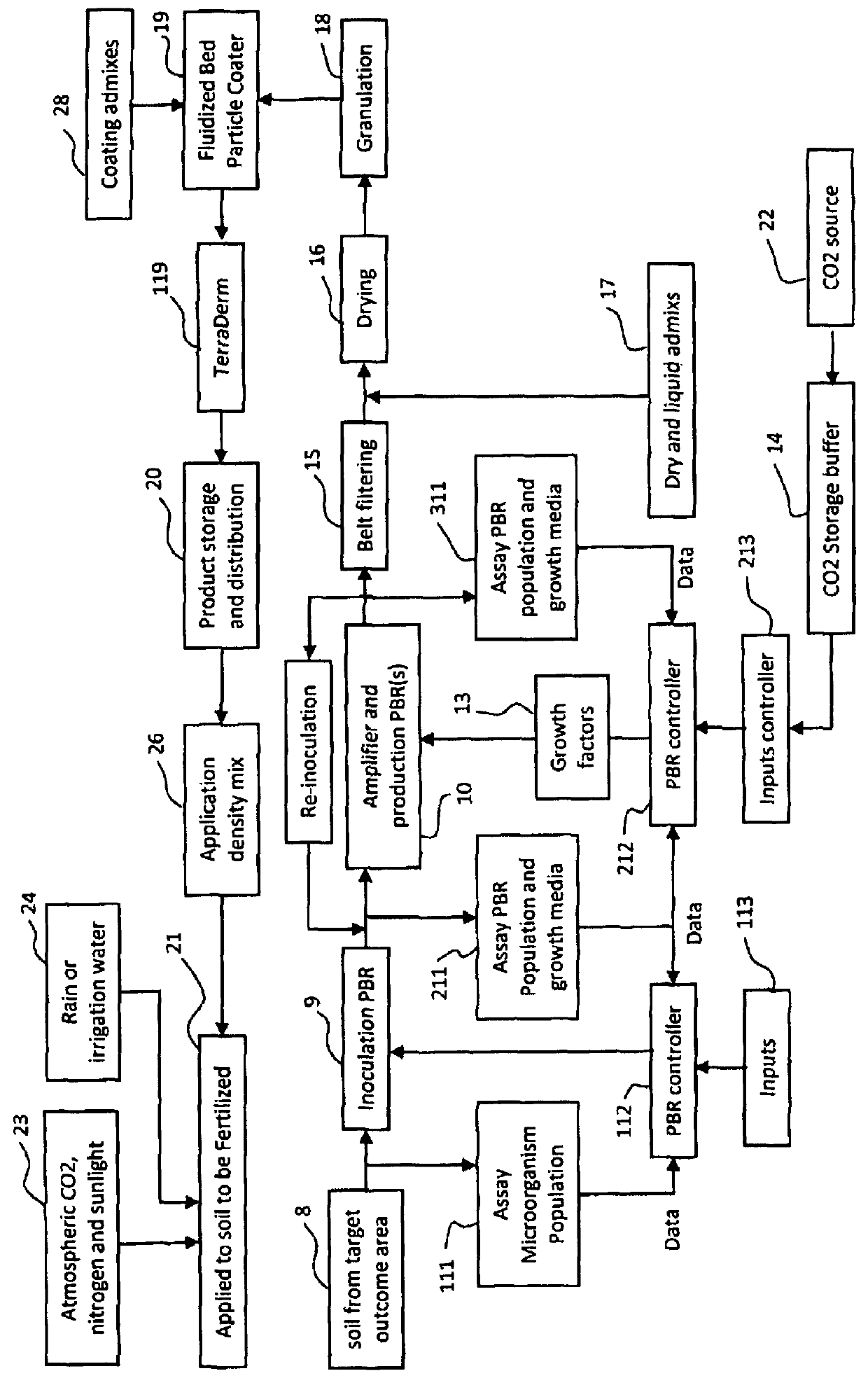

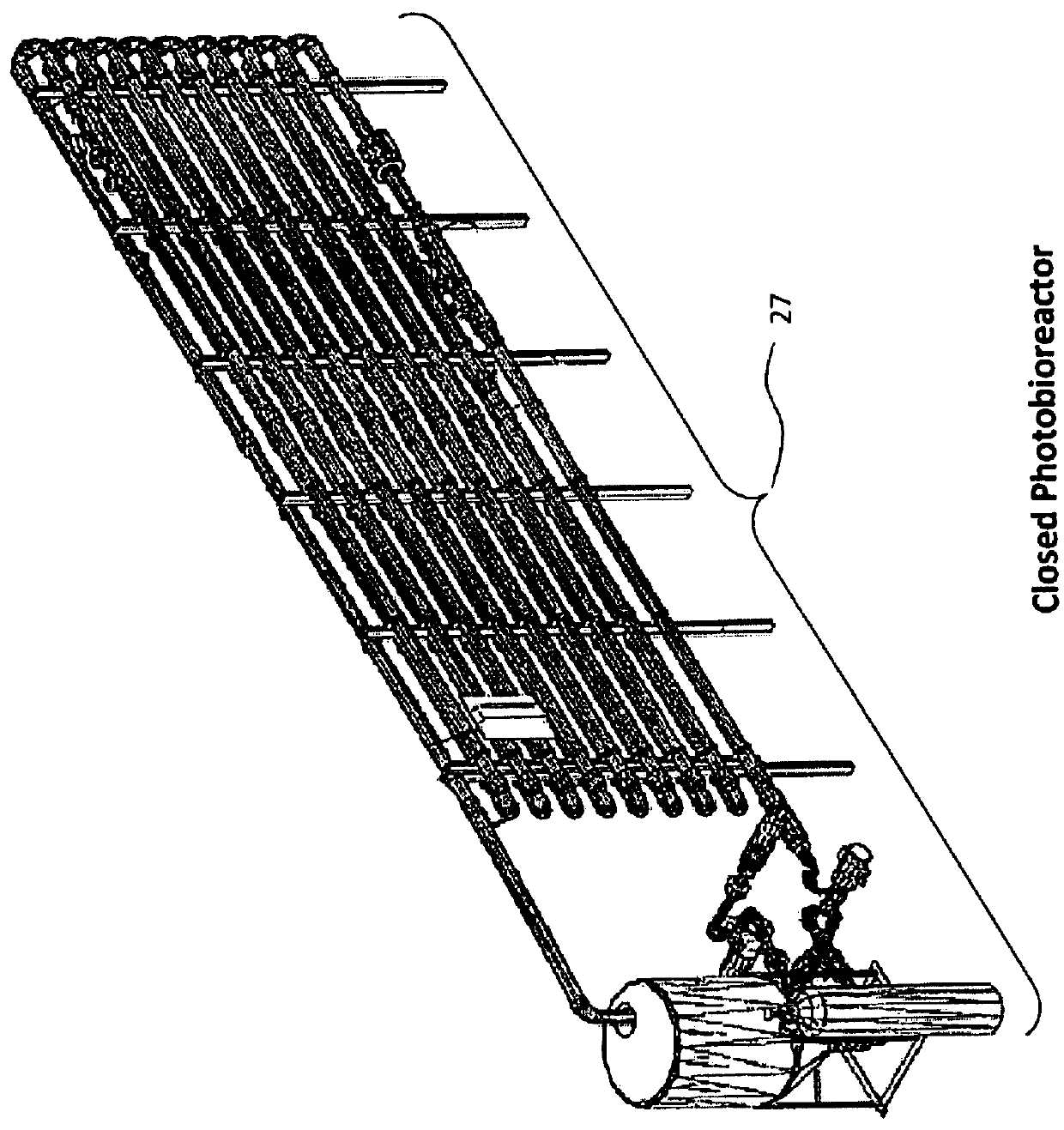

[0066]Referring to FIG. 1, a biological culture of natural soil microorganisms 1 is drawn from their normal residence in the top centimeter of healthy undisturbed soil 105 found in un-shaded areas. These blue-green algae and their soil consortia 1 are cultured into an inoculant and used to inoculate an amplifying Photobioreactor 2, where the culture can be rapidly grown in liquid media via ready access to nutrients, carbon dioxide and sunlight 122. The photobioreactor 2 can be effected through a number of designs differing in levels of performance and features; however the preferred designs are biologically closed so that the soil crust microorganisms 1 can be grown in an environment protected from invasion by competing algal species that may be better adapted for propagating in the aqueous environment. The PBR 2 is fed by sunlight 25, nutrients and a carbon source 122 that is most commonly carbon dioxide, but that may be a fixed form such as sodium bicarbonate or other bio-availabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com