Positive resist composition

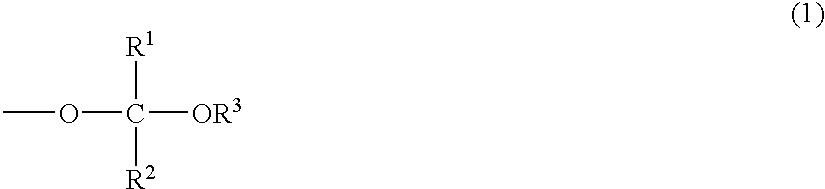

a composition and positive resist technology, applied in the field of positive resist composition, can solve the problems of inability to achieve good profiles, hardly giving such ultra-fine patterning, and inability to meet the practical use of known chemically amplifying positive resists, etc., to achieve high heat resistance, high sensitivity, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

120 g of polyhydroxystyrene having a weight-average molecular weight of 13,000 and a molecular weight distribution (M.sub.w / M.sub.n) of 1.5 were dissolved in 680 g of N,N-dimethyl acetamide, and 85.0 g of di-tert-butyl dicarbonate were added to the resulting solution and stirred to completely dissolve them. Next, 59 g of triethylamine were dropwise added thereto over a period of about 15 minute. After the addition, this mixture was further stirred for about 3 hours. Next, to the resulting solution added was pure water of 20 times the solution. This was further stirred to make polyhydroxystyrene where the hydroxyl groups had been partly substituted by tert-butoxycarbonyloxy groups precipitated therein. The thus-precipitated product was washed with pure water, dewatered and dried to obtain 150 g of polyhydroxystyrene (a weight-average molecular weight of 13,000 and a molecular weight distribution (M.sub.w / M.sub.n) of 1.5) where 39 mol % of the hydroxyl groups had been substituted by...

production example 2

120 g of polyhydroxystyrene having a weight-average molecular weight of 13,000 and a molecular weight distribution (M.sub.w / M.sub.n) of 1.5 were dissolved in 680 g of N,N-dimethyl acetamide, and 42.3 g of 1-chloro-1-ethoxyethane were added to the resulting solution and stirred to completely dissolve them. Next, 78.8 g of triethylamine were dropwise added thereto over a period of about 30 minute. After the addition, this mixture was further stirred for about 3 hours. Next, to the resulting solution added was pure water of 20 times the solution. This was further stirred to make polyhydroxystyrene where the hydroxyl groups had been partly substituted by 1-ethoxyethoxy groups precipitated therein. The thus-precipitated product was washed with pure water, dewatered and dried to obtain 130 g of polyhydroxystyrene (a weight-average molecular weight of 13,000 and a molecular weight distribution (M.sub.w / M.sub.n) of 1.5) where 39 mol % of the hydroxyl groups had been substituted by 1-ethox...

example 1

3 g of polyhydroxystyrene obtained in Production Example 1, in which 39 mol % of the hydroxyl groups had been substituted by tert-butoxycarbonyloxy groups, and 7 g of polyhydroxystyrene obtained in Production Example 2, in which 39 mol % of the hydroxyl groups had been substituted by ethoxyethoxy groups, 0.4 g of bis(cyclohexyl-sulfonyl) diazomethane, 0.1 g of bis(2,4-dimethylphenylsulfonyl) diazomethane, 0.2 g of pylogallol-trimesylate, 0.02 g of salicylic acid and 0.1 g of benzophenone were dissolved in 45 g of propylene glycol monomethyl ether acetate, and 0.03 g of triethylamine and 0.5 g of N,N-dimethylacetamide were dissolved in the resulting solution. The solution was filtered through a 0.2 .mu.m membrane filter to obtain a coating liquid of positive resist.

The thus-prepared coating liquid was coated on a silicon wafer, using a spinner, and dried on a hot plate at 80.degree. C. for 90 seconds to form a resist film having a thickness of 0.7 .mu.m on the wafer. This was exposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com