Storage material without tellurium, preparation method and application

A storage material and memory technology, applied in the field of storage materials, can solve the problems that hinder the development and research of tellurium-containing phase change memory, the threat of semiconductor production line, memory data loss, etc., and achieve the effect of perfect data retention, superior performance and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Prepare silicon-antimony thin films on thermally oxidized silicon substrates by magnetron sputtering co-sputtering method. The argon gas pressure during sputtering is 0.2Pa, and the power on the silicon target and the antimony target is 200 watts of radio frequency respectively. and DC 30 W, the thickness of the prepared film is 200 nm. Energy spectrum analysis shows that the composition of the material is Si 43 Sb 57 .

[0023] 2. Si will be obtained 43 Sb 57 The thin-film storage material was annealed for 5 minutes in a high-purity nitrogen atmosphere.

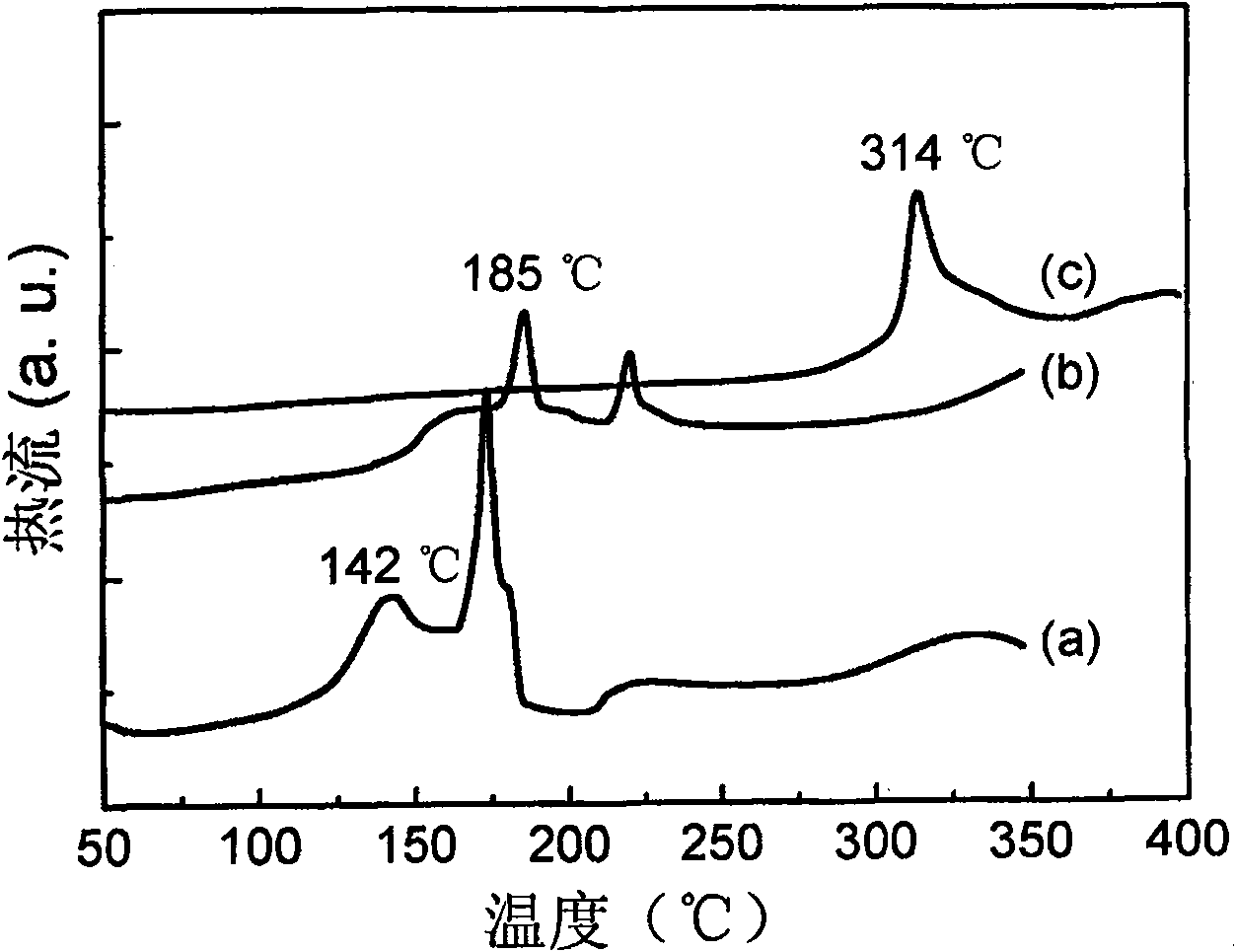

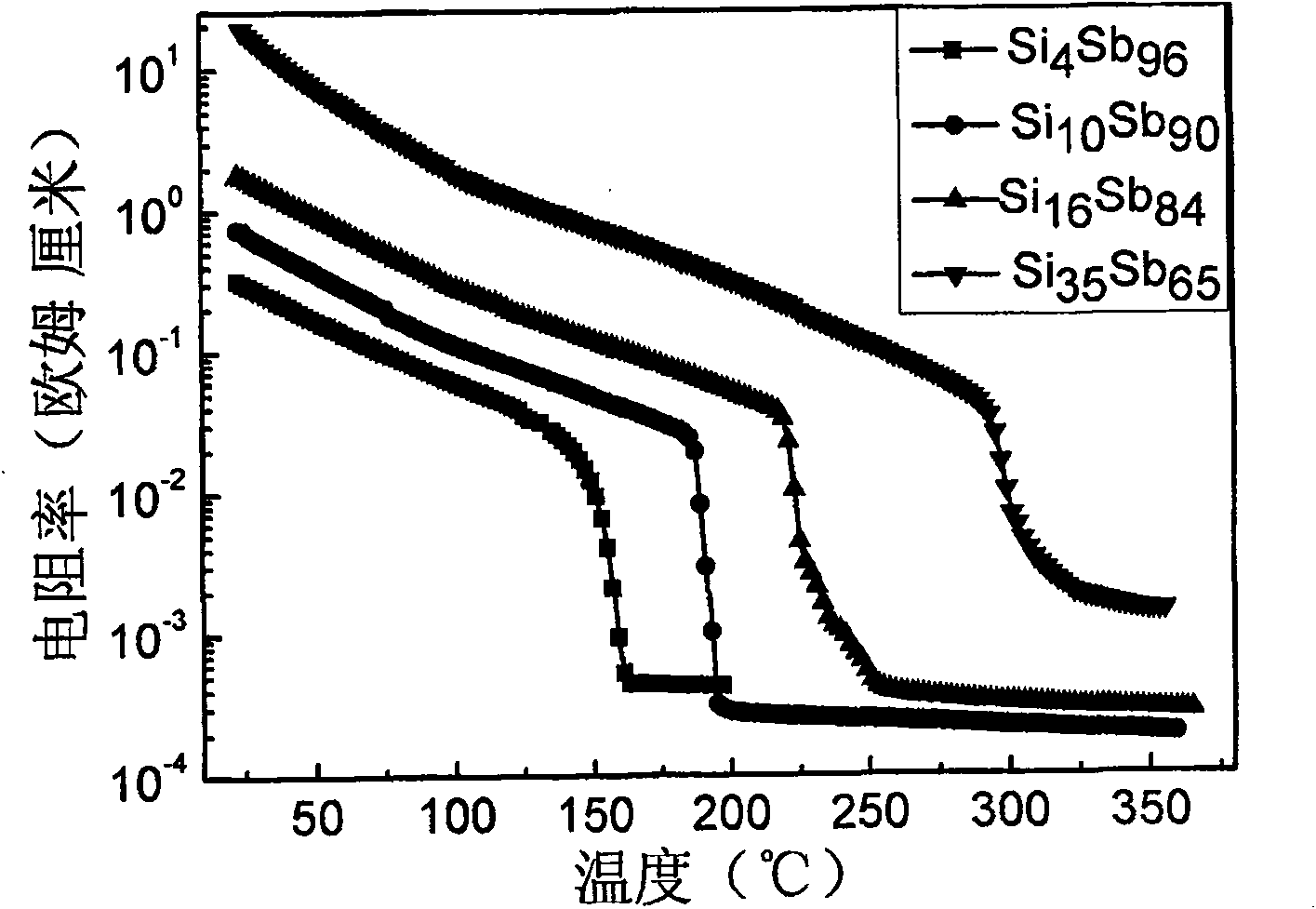

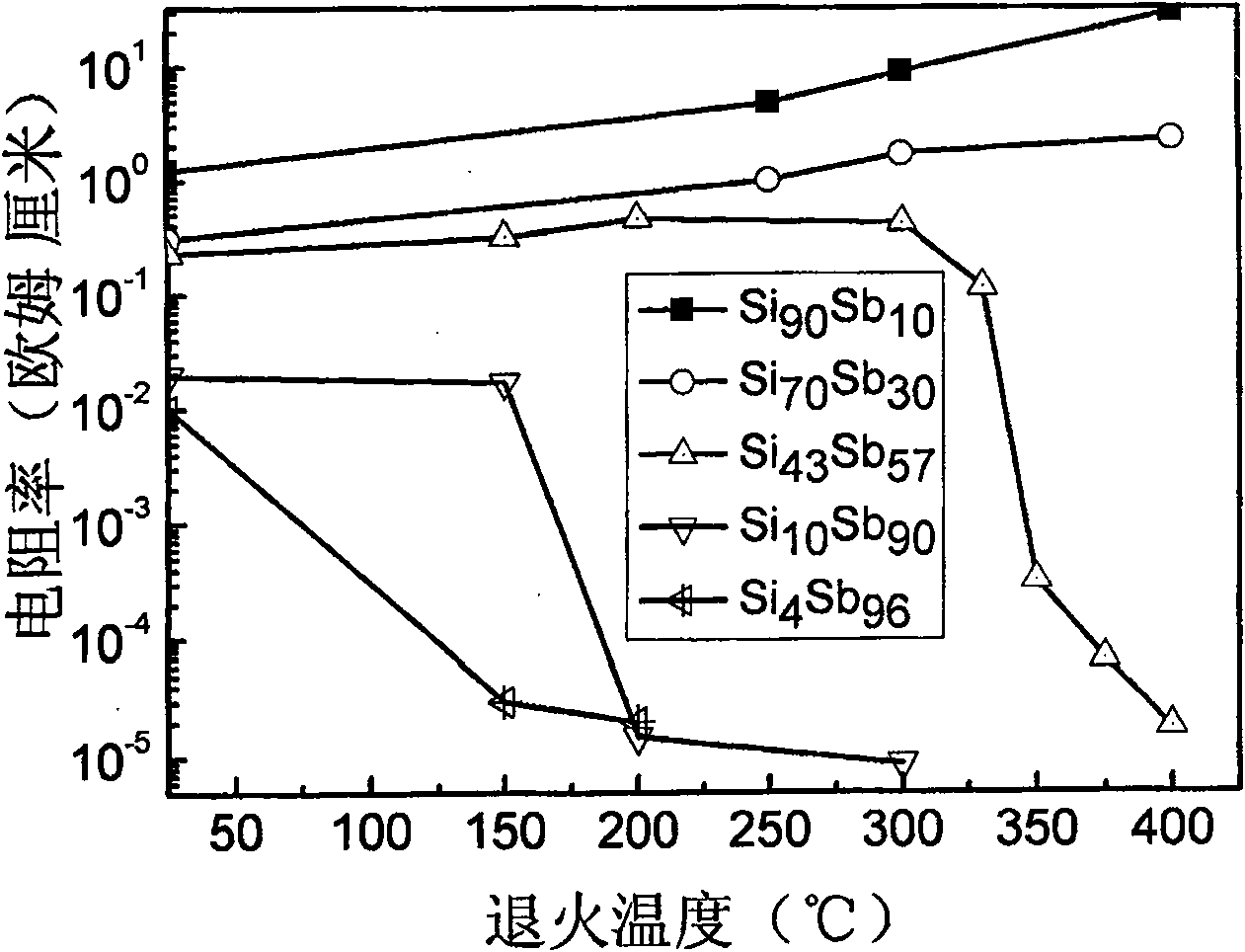

[0024] 3. Si after annealing 43 Sb 57 The material is tested for resistivity, and the test results are as follows: image 3 As shown, Si 43 Sb 57 When the material is annealed below 300°C, the resistivity does not drop but rises, but when the annealing temperature exceeds 350°C, the resistivity drops rapidly. Differential thermal analysis showed that Si 43 Sb 57 The crystallization temperature of the ma...

Embodiment 2

[0026] 1. Magnetron sputtering 100 nm of Au-doped Si on the substrate 16 Sb 82 Thin films, the specific conditions are: the power on the silicon target, the antimony target and the gold target is 100 watts of radio frequency, 30 watts of direct current and 20 watts of direct current respectively, and the argon gas pressure during sputtering is 1Pa.

[0027] 2. The crystallization temperature of the material tested by differential thermal analysis is 225°C.

[0028] 3. The comparison between the gold-doped material and the undoped material is that the crystallization temperature of the material is not much different, but the melting point drops a lot after doping, which is about 550°C, which reduces the energy required to melt it, that is, The power consumption of the storage device is reduced, but the storage device still has a good data retention capability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com