Process and special bacterial colony for degrading phenol organic matter

A technology of organic matter and phenols, which is applied in the field of degrading phenolic organic matter, can solve the problems of low cell concentration and long culture time, and achieve the effects of fast growth, efficient treatment, and stable passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, the acquisition of the mixed microorganism system that degrades phenolic organic matter and its growth stability test

[0029] 1. Screening and domestication of mixed microbial systems for degrading phenolic organic compounds

[0030] Sampling was taken from agricultural soil in the mountainous area of Chongqing, crushed the soil sample, weighed 0.2g into 20ml MNMS medium, and oscillated on a shaker at 30°C. After 2 hours, take 1ml of the culture solution as a seed and insert it into a 70ml glass culture bottle filled with 10ml of MNMS medium, and cover with a rubber stopper. Use a sterilized medical syringe to extract a certain volume of air in the bottle, inject the same volume of methane through a sterilized gas filter, so that the volume ratio of air and methane in the bottle is 1:1, and place it on a shaker at 0°C and 170rpm After culturing for 1 to 2 weeks, a seed culture solution for inoculation is obtained.

Embodiment 2

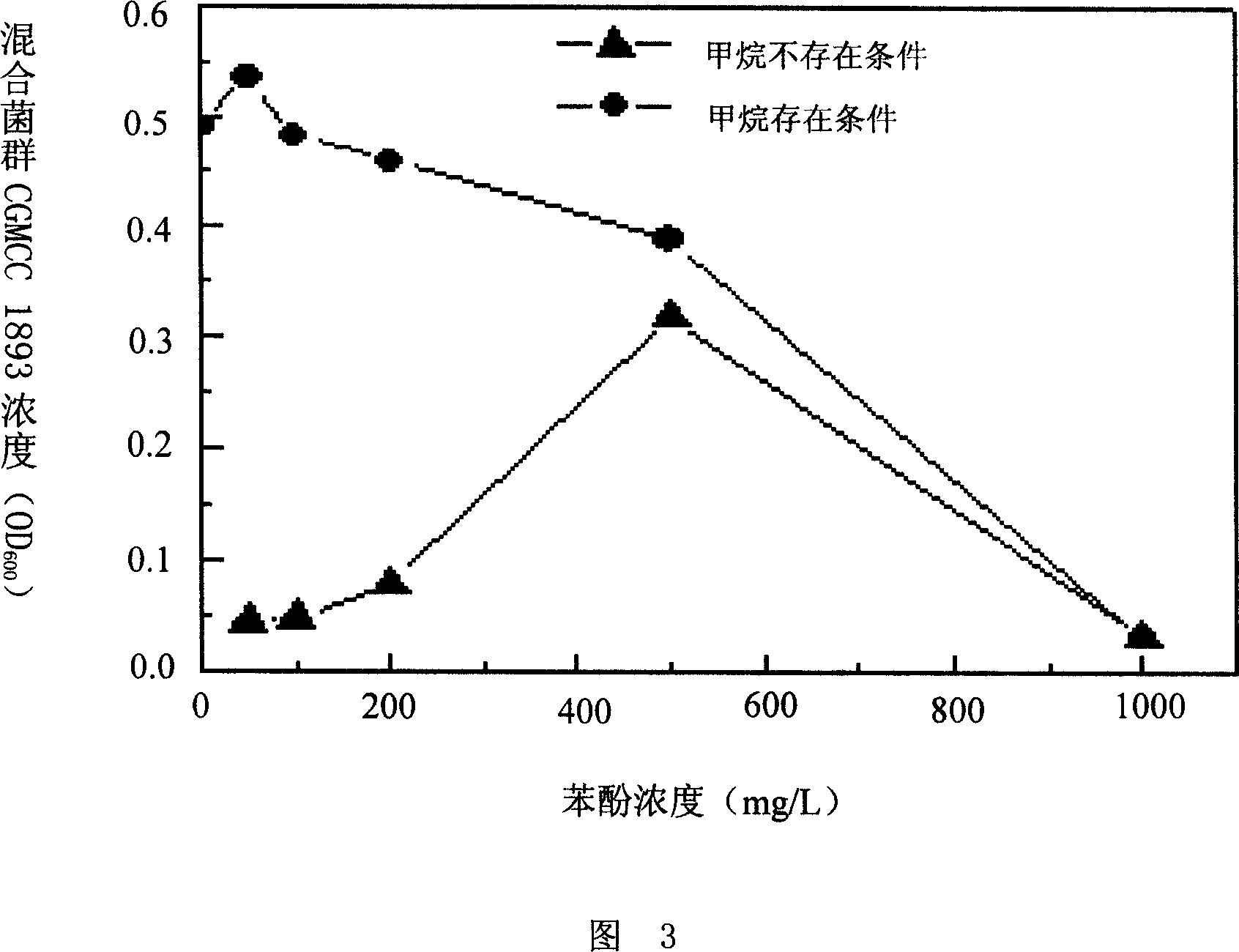

[0045] Example 2, the tolerance of the mixed flora MY9 CGMCC No. 1893 containing Campylobacter phaerogenes to phenol

[0046] The mixed flora MY9 CGMCC No. 1893 containing Campylobacter phaerogenes was inoculated with 50mg / L, 100mg / L, 200mg / L of 4% inoculum (0.32g dry cell weight / L) by volume ratio respectively. , 400mg / L, 1000mg / L phenol MNMS culture medium, after sealing, respectively make the volume ratio of air and methane in the closed environment be 1:1 (methane exists condition), replace methane with air as contrast (methane does not exist condition ), and then cultured at 30° C. on a shaker with a rotation speed of 170 rpm. After culturing for 3 days, the cell concentration of the mixed flora MY9 containing Campylobacter phaerogenes was measured. Phenol was quantitatively analyzed by high-pressure liquid chromatography; the analysis conditions were as follows: C18 chromatographic column, UV detector, mobile phase was 50% methanol water, flow rate was 0.5ml / min, column ...

Embodiment 3

[0048] Example 3, the optimal phenol treatment concentration of the mixed flora MY9 CGMCC No. 1893 containing Campylobacter phaerogenes

[0049] The mixed flora MY9 CGMCC No. 1893 containing Campylobacter phaerogenes MY9 CGMCC No. 1893 is inoculated in the MNMS medium with an inoculum size (0.32g dry cell weight / L) of 4% by volume ratio, and after sealing, make the mixture in the closed environment The volume ratio of air to methane was 1:1, and the mixed flora MY9 containing Campylobacter phaerogenes grown to the logarithmic growth phase was collected by centrifugation, resuspended in phosphate buffer solution, and the wet cells were collected by centrifugation (OD 600 =0.5), 5ml of wet thalline was inoculated in 95mL of MNMS substratum containing 600mg / L phenol, divided into three parts, after sealing, cultivated in the following environment species respectively:

[0050] Environment 1): Make the volume ratio of air and methane in the bottle to be 1:1, and then shake the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com