Multilayer copolymerized compound membrane soft bagged inosine in sodium chloride injection composition and its manufacturing method

A technology of inosine sodium chloride, multi-layer co-extrusion, applied in the field of medicine, can solve the problems of easy side effects, PVC soft bags are not easy to be degraded and recycled, storage area is large, etc., to achieve stable infusion concentration, excellent thermal welding Sealing effect, low water vapor permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

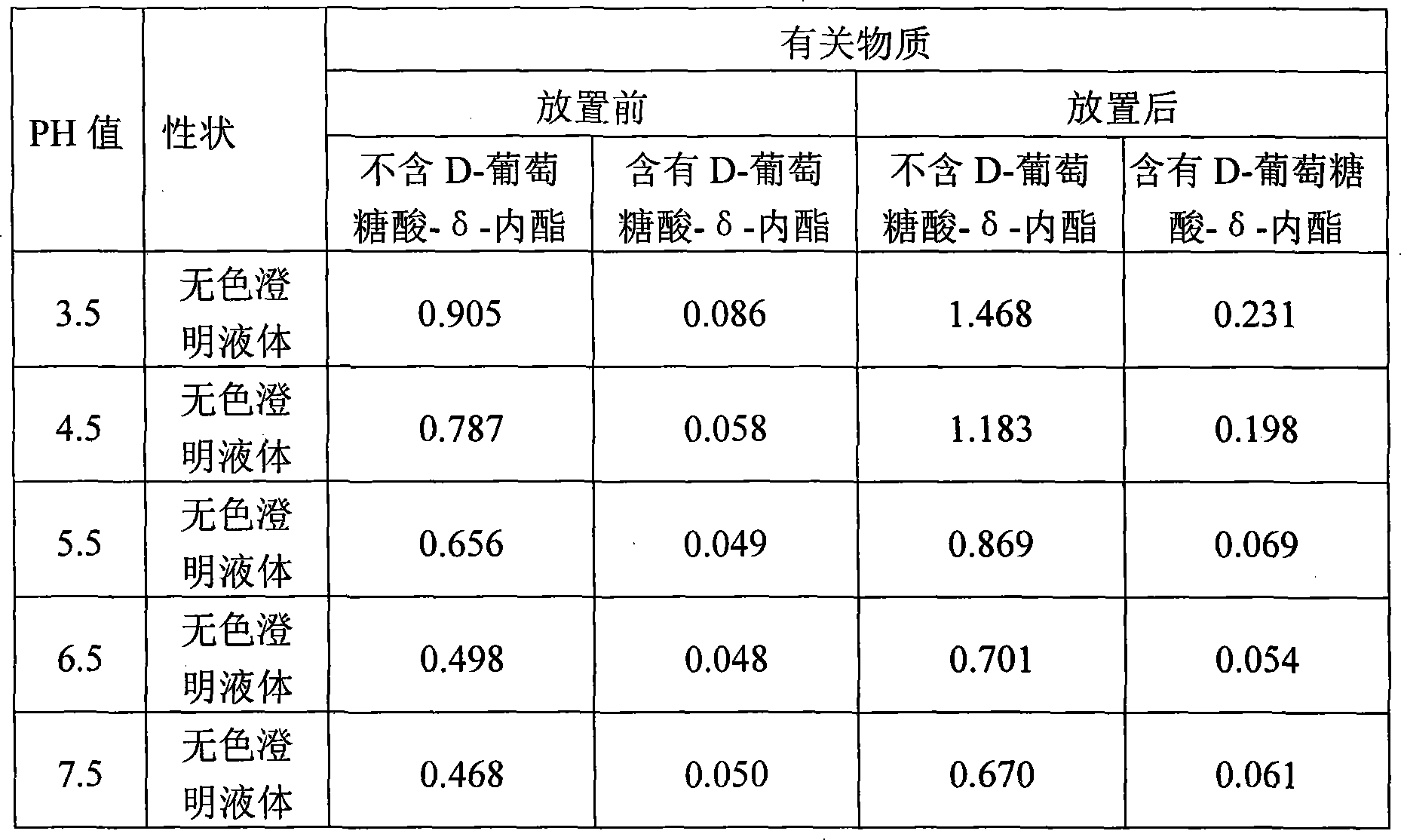

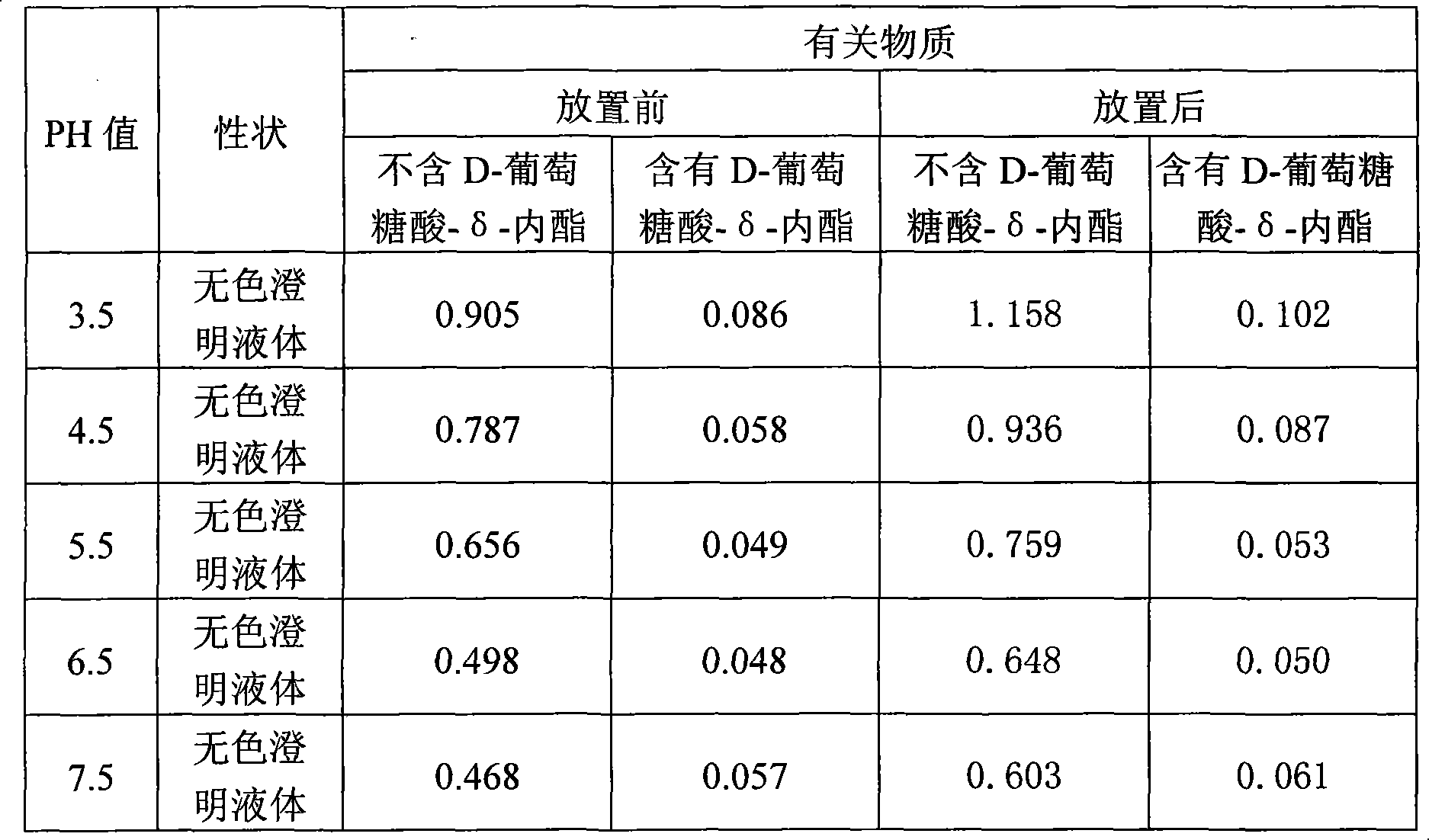

[0015] Embodiment 1: According to the proportion that every 100ml inosine sodium chloride injection composition contains inosine 0.6g, sodium chloride 0.9g, weigh inosine, add the water for injection of about 80% of the total amount, after stirring evenly, add Sodium chloride, stir to dissolve, add water for injection to nearly full amount, stir well, add 0.03wt% activated carbon for needles, stir evenly, filter and remove activated carbon after standing, add water for injection to full amount, adjust pH value to 7.5. After the semi-finished product passes the inspection, it is filtered with 0.45 μm and 0.22 μm microporous membranes in turn to obtain the composition of inosine sodium chloride injection; in the 100-class clean area, it is polymerized by modified ethylene propylene sequentially from the inside to the outside. layer, polyethylene layer, polyethylene layer, ethylene methacrylate polymer layer and polyester copolymer layer (purchased from Sealed Air Packaging (Shang...

Embodiment 2

[0016] Embodiment 2: According to the ratio that every 100ml inosine sodium chloride injection composition contains inosine 0.6g, sodium chloride 0.9g, D-glucono-δ-lactone 0.1g, weigh inosine and D-glucose Acid-δ-lactone and mix to obtain a mixture, then add about 80% of the total amount of water for injection, heat to 52°C, stir until the mixture of inosine and D-glucono-δ-lactone is completely dissolved, cool down to room temperature, and then add Sodium chloride, stir to dissolve, add water for injection to 90% of the total amount, stir well, add 0.03wt% activated carbon for needles, stir evenly, filter and remove the activated carbon after standing, add water for injection to the full amount, and use D-gluconic acid- δ-lactone adjusts the pH value to 6.5, and the inosine sodium chloride injection composition is obtained by filtration through a microporous membrane; in a class 100 clean area, the multilayer co-extruded composite film and plastic infusion as described in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com