Ultraviolet curing acrylic ester/modified montmorillonite nano composite material and preparation thereof

A nano-composite material and acrylate technology, applied in the treatment of dyed low molecular organic compounds, fibrous fillers, etc., can solve the problems of high price, low degree of organic modification of montmorillonite, and failure to achieve substantial improvement in material performance. , to achieve the effects of improved mechanical properties and heat resistance, simple and easy modification methods, and broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

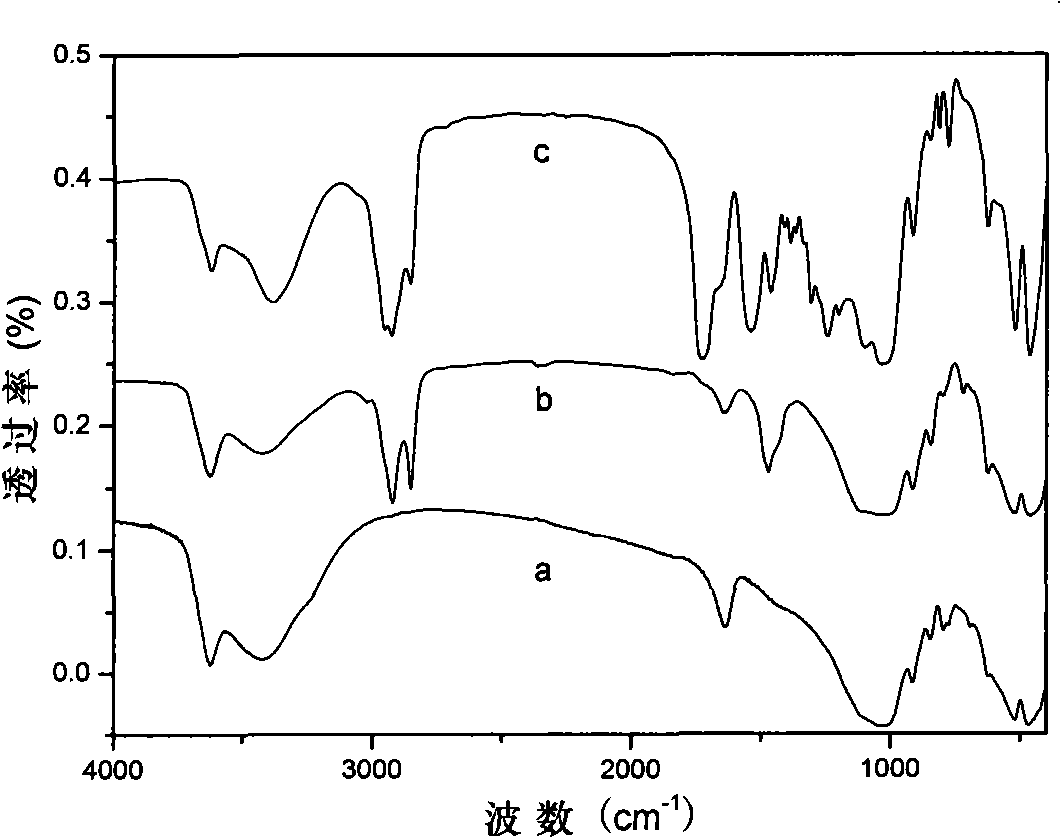

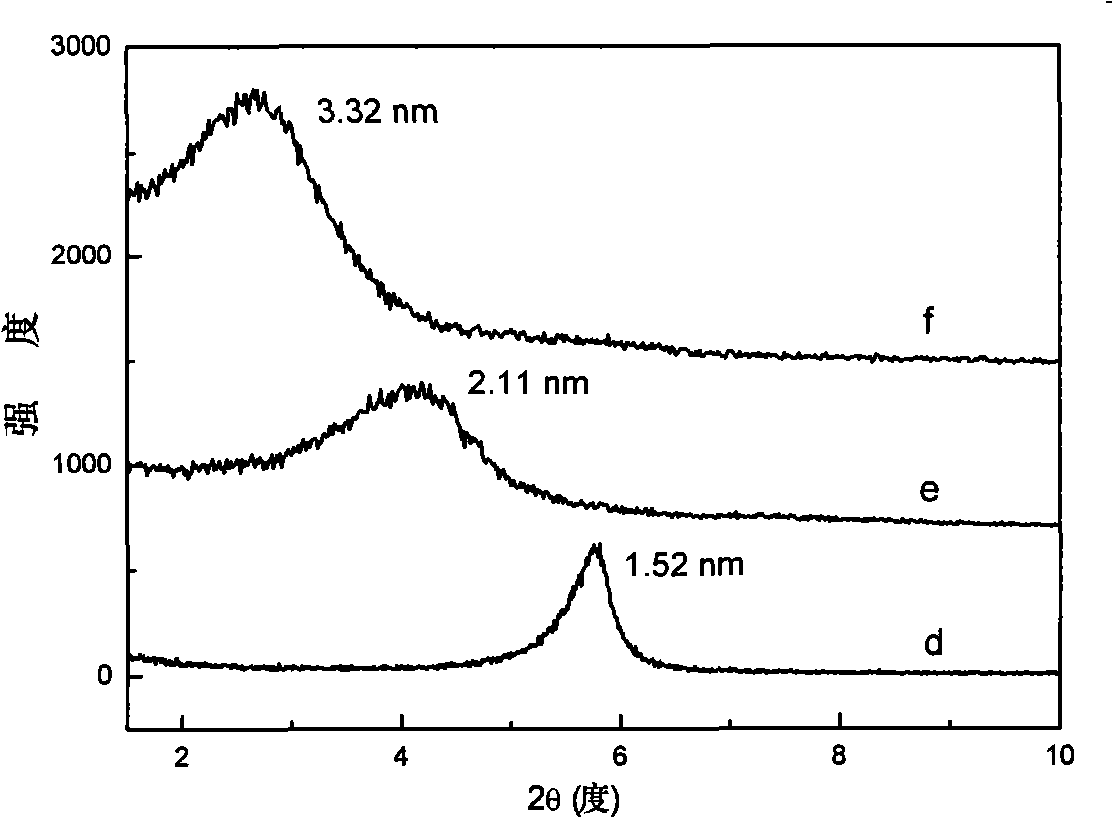

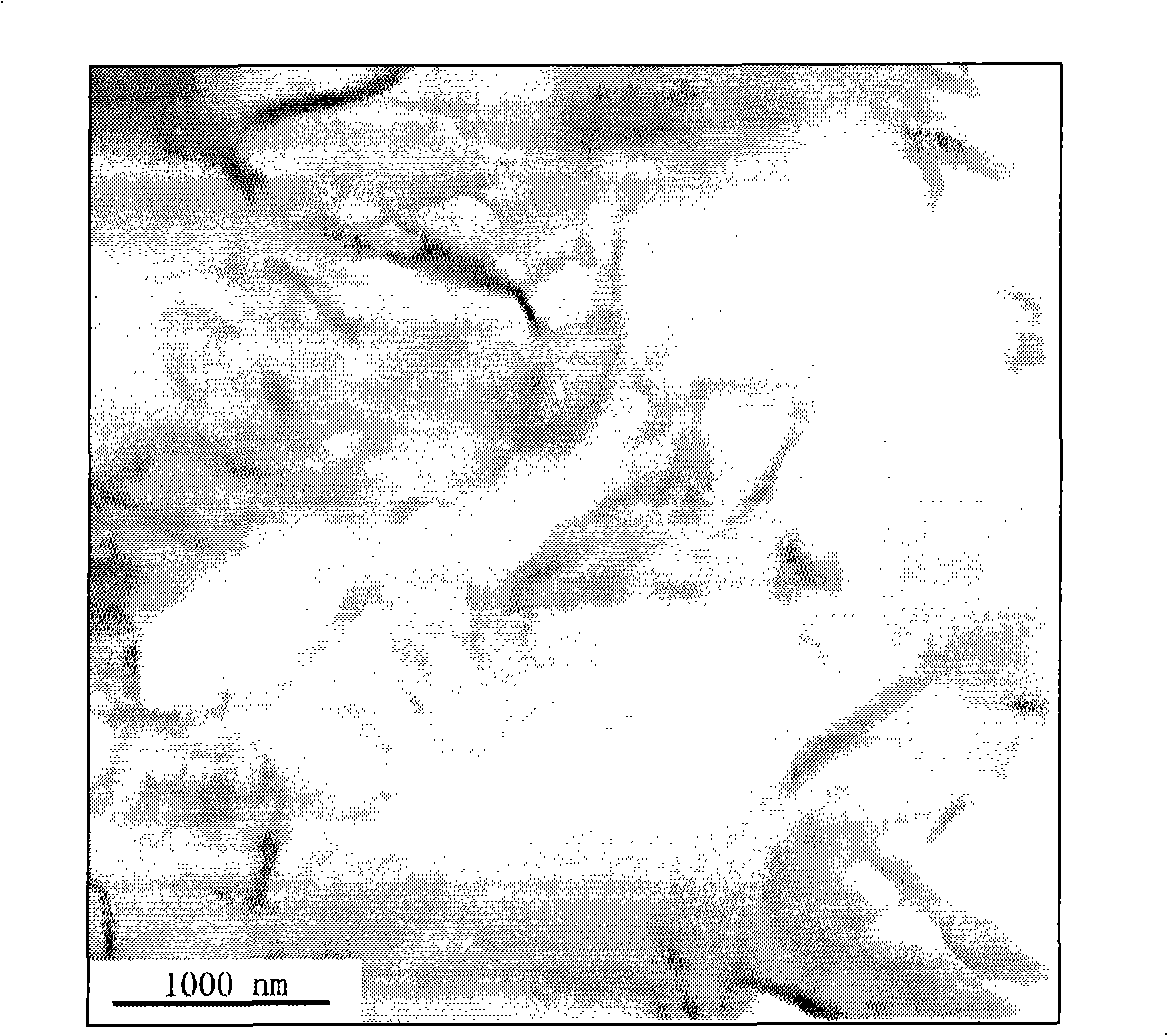

Method used

Image

Examples

Embodiment 1

[0035] Under nitrogen atmosphere and ice-water bath conditions, add 0.20mol diphenylmethylene diisocyanate, 300mL toluene and 0.05wt% dibutyltin laurate into a 500mL three-necked flask, and add 0.20mol methyl 2-Hydroxyethyl acrylate was slowly added dropwise to the three-necked flask at a rate of 10 drops / min. After the dropping, the reaction was continued for 4 hours in an ice-water bath, then the temperature was raised to 60°C, and the amount of double bond of the reactant was added. A few 0.5% p-hydroxyanisole was reacted for 4 hours to obtain a toluene solution of acrylate modifier 1 with a mass concentration of 0.27 g / mL.

[0036] Add 10g of Na-montmorillonite (Na-MMT) and 400mL of distilled water to a 1000mL flask. After stirring for 1 hour at 80°C at 500 rpm, add 1g of cetyltrimethylammonium chloride and continue stirring After 12 hours, filter and wash with distilled water to obtain the product (Na-MMT-1); disperse 10 g of the product (Na-MMT-1) in 200 mL of distilled wate...

Embodiment 2

[0046] Under nitrogen atmosphere and ice-water bath conditions, 0.20 mol of isophorone diisocyanate, 300 mL of tetrahydrofuran, and 0.2wt% of dibutyltin laurate were added to a 500 mL three-necked flask, and 0.20 mol of acrylic acid-2- Hydroxyethyl ester was slowly added dropwise to the three-necked flask. After the dropping, the reaction was continued for 2 hours under ice-water bath conditions, and then the temperature was raised to 50°C. Hydroquinone accounting for 0.5% of the double bond moles of the reactant was added and reacted for 8 hours , A tetrahydrofuran solution of acrylate modifier 2 with a mass concentration of 0.25 g / mL was obtained.

[0047] Add 20 g of K-montmorillonite and 200 mL of distilled water into a 500 mL flask, stir at 60°C at 3000 rpm for 1 hour, add 0.5 g of cetyltrimethylammonium chloride and cetyltrimethyl 0.5g ammonium bromide, continue to stir for 24 hours, filter and wash with distilled water to obtain the product; take 10g product dispersed in 30...

Embodiment 3

[0050] Under nitrogen atmosphere and ice-water bath conditions, 0.20mol of toluene diisocyanate, 200mL of dioxane, 100mL of toluene and 0.1wt% of dibutyl stannous oxide were added to a 500mL three-necked flask, and 0.20mol of acrylic acid- 2-Hydroxypropyl ester was slowly added dropwise to the three-necked flask. After dropping, the reaction was continued for 3 hours under ice-water bath conditions, and then the temperature was raised to 55°C. Phenol accounting for 0.3% of the double bond of the reactant was added and reacted for 6 hours. A toluene / dioxane solution of acrylate modifier 3 with a mass concentration of 0.22 g / L was obtained.

[0051] Add 5g of Na-montmorillonite, 5g of Li-montmorillonite and 200mL of distilled water into a 500mL flask, stir for 1 hour at 70°C at 2000 rpm, then add 0.1g of octadecyltrimethylammonium bromide After stirring for 48 hours, filter and wash with distilled water to obtain the product; disperse 10g of the product in 200mL of distilled water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com