Composite coating cardiovascular medicaments elution stent and preparation thereof

A composite coating and stent-eluting technology, applied in stents, coatings, medical sciences, etc., can solve the problem that the anti-proliferation performance of stents needs to be improved, the stability of heparin on the surface of stents is not ideal, and thrombosis cannot be obtained. Progress and other issues to achieve the effect of promoting adhesion and growth, excellent mechanical properties, and inhibiting excessive proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

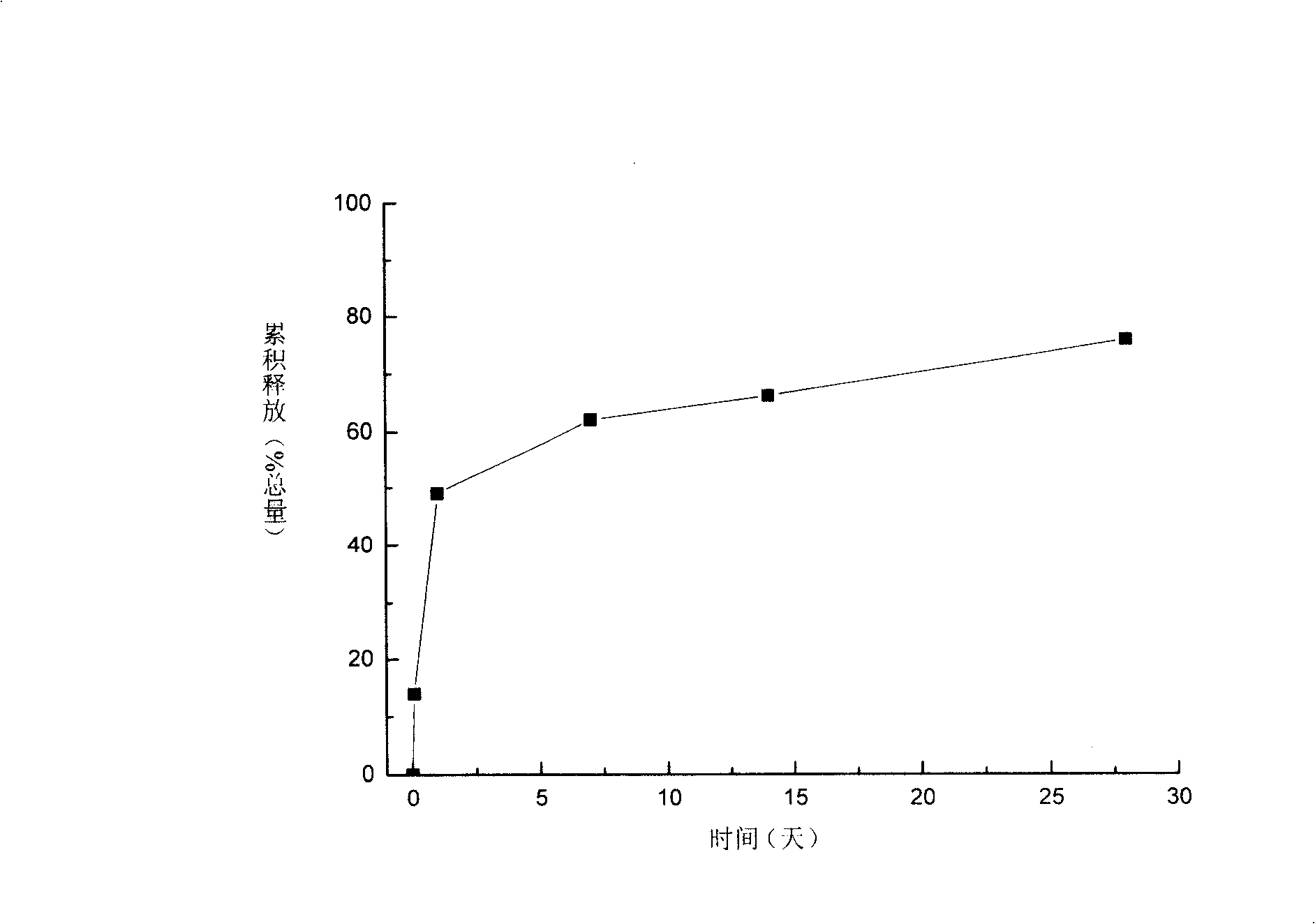

Image

Examples

Embodiment 1

[0037] The first step: prepare the bottom solution according to the following formula

[0038] Polyurethane (Biospan, U.S. Polymer Technology Group company) (15% solid content, dimethylacetamide solvent) 10 grams

[0039] N,N-Dimethylacetamide 90g

[0040] Heparin 1.0g

[0041] Polyisocyanate (Desmodur N3400, Bayer Company) 0.8 g

[0042] The second step: prepare the surface layer solution according to the following formula

[0043] PLA (Mn=120000) 2.2 grams

[0044] Tetrahydrofuran (chromatographic grade) 250 grams

[0045] Paclitaxel (purity>99.5%) 0.4g

[0046] Step 3: Make the Stand

[0047] Ultrasonic cleaning the magnesium alloy stent with isopropanol for 5 minutes, blowing and drying at 50°C for 20 minutes, after drying, use the method of spraying or dipping to make the bottom layer solution evenly and completely cover the surface of the alloy stent, and then dry at 30°C for 50 minutes Minutes, after the completion of drying at 60 ° C for 2 hours, after drying, s...

Embodiment 2

[0049] The first step: prepare the bottom solution according to the following formula

[0050] Polyurethane aqueous emulsion (NeoRez-972, Zeneca Resins company) 10 grams

[0051] water 90g

[0052] Heparin 3 grams

[0053] The second step: prepare the surface layer solution according to the following formula

[0054] PLA (Mn=130000) 5.5 grams

[0055] Tetrahydrofuran (chromatographic grade) 270 grams

[0056] Rapamycin (purity>95%) 1.65g

[0057] Step 3: Make the Stand

[0058] Clean the cobalt-chromium alloy stent ultrasonically with isopropanol for 5 minutes, then wash it with deionized purified water for 5 minutes, and dry it with air at 50°C for 20 minutes. After drying, use the method of spraying or dipping to make the underlying solution even and complete coverage On the surface of the alloy stent, dry at 30°C for 50 minutes after completion, and blow dry at 60°C for 2 hours after completion. After drying, use the method of spraying or dipping to make the surface s...

Embodiment 3

[0060] The first step: prepare the bottom solution according to the following formula

[0061] Polyurethane aqueous emulsion (Sancure 1601, Lubrizol company) 10 grams

[0062] water 90g

[0063] Heparin 3 grams

[0064] The second step: prepare the surface layer solution according to the following formula

[0065] Polylactic acid-glycolic acid copolymer (PLGA, Mn=130000, LA / GA=80 / 20) 3.5 grams

[0066] Tetrahydrofuran (chromatographic grade) 250 grams

[0067] Rapamycin (purity>99.5%) 1.1g

[0068] Step 3: Make the Stand

[0069] Clean the cobalt-chromium alloy stent ultrasonically with isopropanol for 5 minutes, then wash it with deionized purified water for 5 minutes, and dry it with air at 50°C for 20 minutes. After drying, use the method of spraying or dipping to make the underlying solution even and complete coverage On the surface of the alloy stent, dry at 30°C for 50 minutes after completion, and blow dry at 60°C for 2 hours after completion. After drying, use th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com