Electroplating method for assembling nano-micrometre array material in metal aluminium stencil

A technology of metal aluminum and aluminum templates, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of increased preparation costs and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

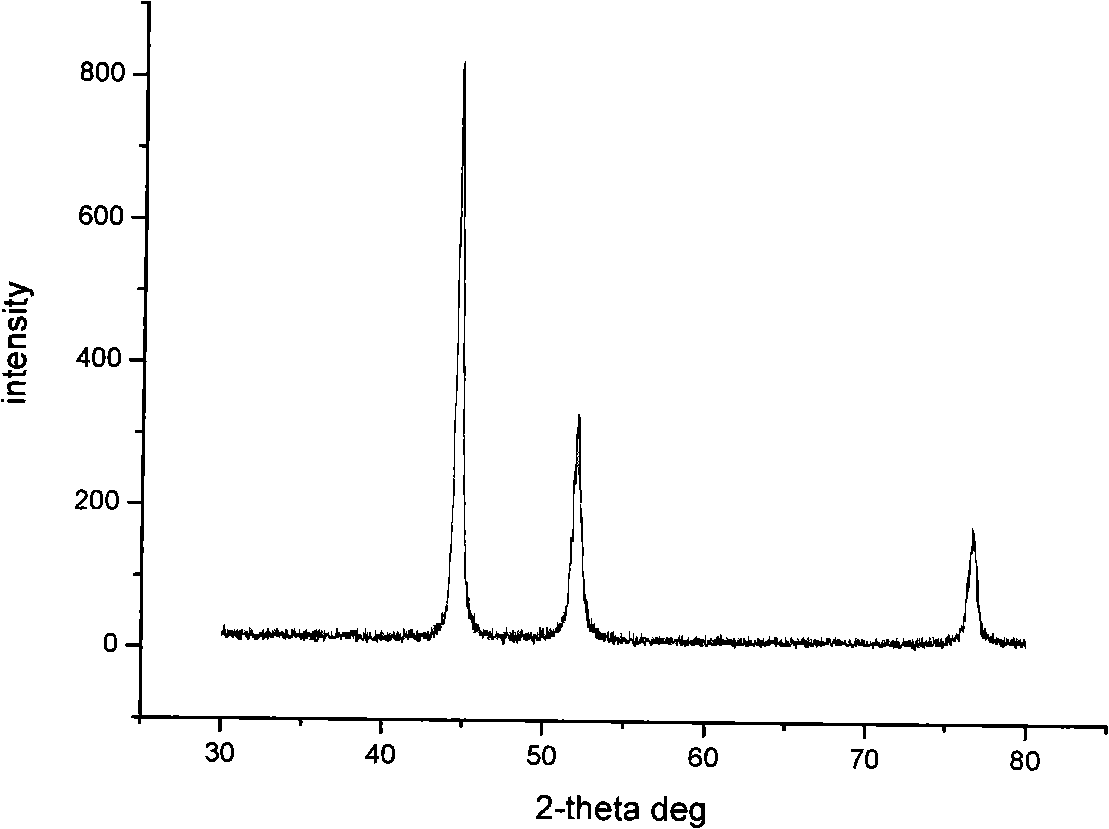

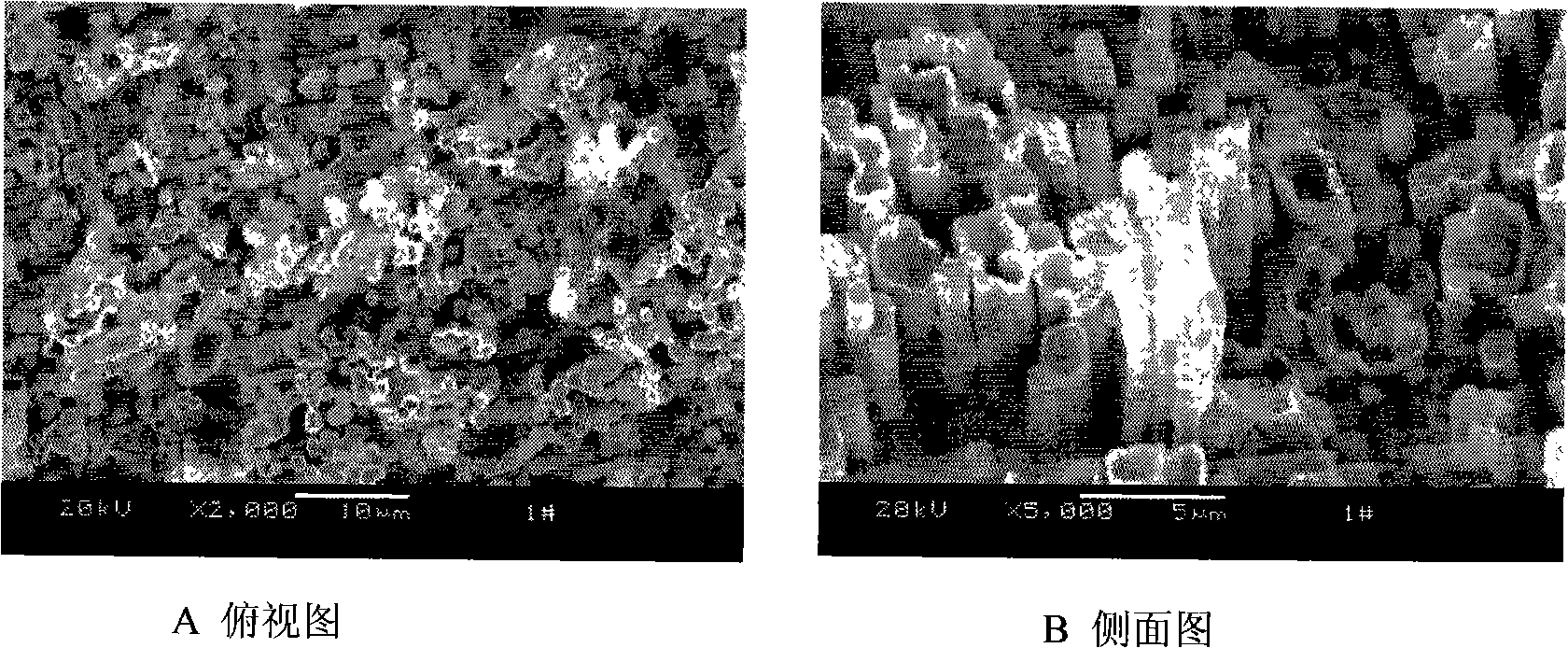

Embodiment 1

[0020] Example 1: The template is immersed in 1% HCl, taken out and rinsed with clean water, and finally immersed in absolute ethanol, taken out to complete the pretreatment process. The pretreated aluminum tunnel hole template is placed in a nickel electroplating solution as a cathode, and a nickel plate is used as an anode. Electroplating solution is 350g / L NiSO 4 ·6H 2 O and 30g / L H 3 BO 3 The mixed solution was adjusted with NaOH solution so that the pH of the mixed solution was 4.3. The current density is 500.0A / m 2 , The power-on time is 1h. After plating, take out the metal aluminum tunnel hole template and clean it with water. Then use 5.0% NaOH solution to dissolve the aluminum tunnel hole template. The resulting film is washed with water to remove the remaining lye on the surface, and then dried.

[0021] The operation steps of other nickel electroplating examples are as described in Example 1, and the process conditions of Examples 2 to 4 are as shown in Table 1.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com