Aqueous polymer-olefin dual-layer coated controlled release fertilizer and preparation thereof

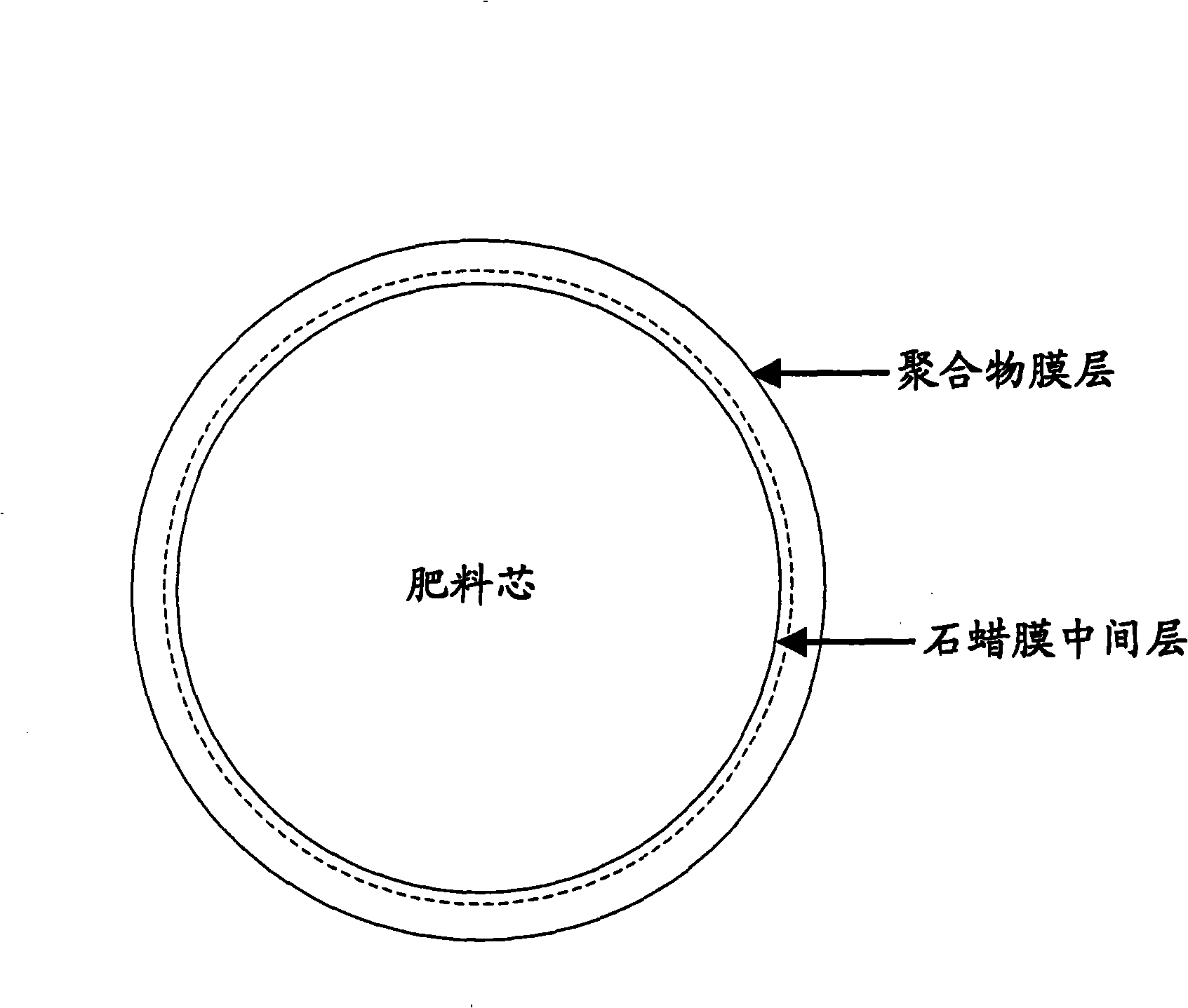

A water-based polymer and controlled-release fertilizer technology, applied in the direction of layered/coated fertilizers, fertilizer forms, fertilizer mixtures, etc., can solve the problem of not disclosing the type, composition and properties of water-soluble resin coating agents, and not completely eliminating organic solvents Harm, reduce nutrient controlled release performance and other issues, to achieve the effect of excellent controlled release performance, low cost, impact resistance, wear resistance and controlled release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of water-based polymer composite coating agent

[0048] Using the polymerization process (A), 900 grams of water, 13 grams of sodium lauryl sulfate, 6 grams of n-octanol and 8 grams of ammonium bicarbonate, stirring to dissolve. Dissolve 8 grams of ammonium persulfate in 100 grams of water for use. Put 510 grams of styrene, 470 grams of butyl acrylate and 20 grams of acrylic acid into the dropping funnel and mix evenly, then add 20% of the mixed monomer into the reaction bottle, stir and add 60 ml after heating to about 60 °C Ammonium persulfate aqueous solution, and at the same time drop the remaining mixed monomers at a constant speed. The rate of monomer addition is controlled so that the reaction temperature is controlled at about 85° C., and the addition time is about 2 hours. After dropping, the remaining 40 ml of ammonium persulfate aqueous solution was added and reacted at about 85° C. for 4 hours. Cool to room temperature, adjust the pH valu...

Embodiment 2

[0053] (1) Preparation of water-based polymer composite coating agent

[0054] Equipment and polymerization process are with embodiment 1. The difference is that 450 grams of methyl methacrylate, 490 grams of butyl acrylate, 60 grams of acrylic acid, 10 grams of sodium lauryl sulfate, 12 grams of octylphenol polyoxyethylene ether, 5 grams of n-octanol, and persulfuric acid Ammonium 12 grams, ammonium bicarbonate 12 grams, water 1000 grams. The viscosity of the product is 48mPa.S, the particle size is 82nm, and the glass transition temperature of the polymer is 25.1°C.

[0055] Disperse 70 grams of potato starch in 300 grams of water, heat to about 75° C. for gelatinization under stirring for 1 hour, add it into the above emulsion under strong stirring and mix evenly to obtain a composite coating agent.

[0056] (2) Fertilizer coating process

[0057] 10kg particle diameter is 3~4 millimeters of large particle urea (from Shandong Mingshui Chemical Co., Ltd., is 46.4 in N wei...

Embodiment 3

[0059] (1) Preparation of water-based polymer composite coating agent

[0060] Using the polymerization process (C), add 500 g of water, 2.5 g of sodium dodecylbenzenesulfonate, 2.5 g of sodium dodecyl sulfate and 4 g of polyoxyethylene sorbitan monooleate into a round bottom flask in sequence in, stir to dissolve. Mix 390 grams of styrene, 570 grams of ethyl acrylate and 40 grams of acrylic acid evenly, then add 80% of the mixed monomer into the above-mentioned round bottom flask, and emulsify at a rate of 700 rpm for 45 minutes at room temperature, and the monomer The pre-emulsion was transferred to the dropping funnel for use. Dissolve 10 grams of potassium persulfate in 100 grams of water for later use.

[0061]Add 400 g of water, 2.5 g of sodium dodecylbenzenesulfonate, 2.5 g of sodium dodecylsulfate, 4 g of poly Oxyethylene sorbitan monooleate, 4 grams of n-octanol and 15 grams of sodium bicarbonate were dissolved evenly under stirring, and then the remaining 20% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com