Zinc oxide suspending agent

A technology of zinc oxide and suspending agent, applied in the field of agricultural trace element fertilizer, can solve the problems of difficult environmental pollution, easy to produce phytotoxicity, slow speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

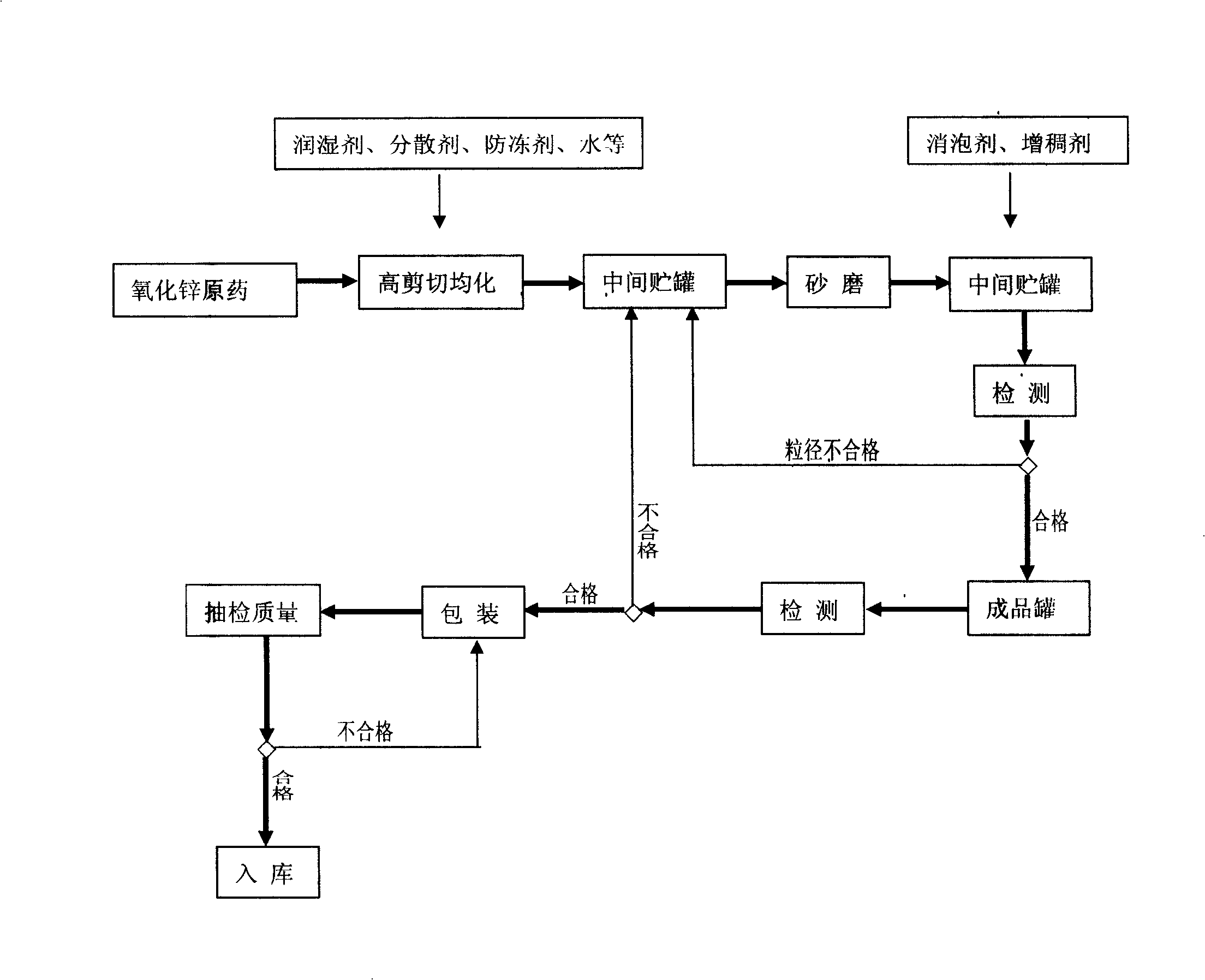

Method used

Image

Examples

Embodiment 1

[0025] Weigh 71% of zinc oxide raw powder, 2% of wetting agent nonylphenol ethoxylate (10EO), 4% of dispersant phenethylphenol polyoxyethylene ether formaldehyde condensate, 1% of sodium lignosulfonate, antifreeze Ethylene glycol 4%, water 17%, the above raw materials are mixed according to the general method, poured into a high shear homogenizer for stirring, and then poured into a sand mill for sanding, and then add a thickener after sanding 0.3% of xanthan gum and 0.7% of polyoxyethylene fatty acid ester as a defoaming agent are fully stirred to obtain a 70% zinc oxide suspending agent. After inspection, the effective ingredient is zinc oxide 70.2%, PH value 7.9, suspension rate ≥ 93%, sieving (through 75μm test sieve) ≥ 99.5%, mercury, arsenic, cadmium, lead, chromium harmful substances content ≤ 0.05%, residual after dumping content ≤ 3%, residue ≤ 0.05% after washing, and the stability of accelerated hot storage and accelerated cold storage is qualified. In practical ap...

Embodiment 2

[0027] Weigh 71% of zinc oxide raw powder, 4% of wetting agent styrene ethylphenol polyoxyethylene ether sodium sulfate, 4% of dispersing agent nonylphenol ether phosphate, 4% of antifreeze ethylene glycol, 16.2% of water, the above The raw materials are mixed according to the general method, poured into a high-shear homogenizer for stirring, and then poured into a sand mill for sanding. After sanding, add thickener methyl cellulose 0.3% and defoamer fatty acid polyoxygen Vinyl ester 0.5%, get 70% zinc oxide suspending agent after fully stirring. After inspection, the effective ingredient is zinc oxide 70.1%, PH value 7.8, suspension rate ≥ 92%, sieving (passing 75μm test sieve) ≥ 99%, mercury, arsenic, cadmium, lead, chromium harmful substances content ≤ 0.05%, residual after dumping content ≤ 2%, residue ≤ 0.05% after washing, and the stability of accelerated heat storage and accelerated cold storage is qualified. In practical application, it is used to prevent and treat zi...

Embodiment 3

[0029] Weigh 51% of zinc oxide powder, wetting agent sodium alkylbenzene sulfonate 6%, dispersant fatty alcohol ether succinate half ester sodium sulfonate 7%, antifreeze agent polyethylene glycol 3.5%, water 31%, Mix the above raw materials according to the general method, pour them into a high-shear homogenizer for stirring, and then pour them into a sand mill for sand milling. After sand milling, add the thickener carboxymethyl cellulose hydroxyethyl cellulose 0.8 % and 0.7% of antifoaming agent sec-butanol, after fully stirring, 50% zinc oxide suspending agent was obtained. After inspection, the active ingredient is zinc oxide 50.3%, PH value 8.0, suspension rate ≥ 93%, sieving (through 75μm test sieve) ≥ 99.5%, mercury, arsenic, cadmium, lead, chromium harmful substances content ≤ 0.05%, residual after dumping content ≤ 2%, residue ≤ 0.05% after washing, and the stability of accelerated heat storage and accelerated cold storage is qualified. In practical application, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com