Preparation method of aliphatic polyester-chitosan composite fiber tissue repair bracket

An aliphatic polyester and composite fiber technology, used in stents, medical science, prostheses, etc., can solve the problems of uneven properties at the microscopic level of materials, and achieve good cell adhesion, good mechanical properties, and high porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of aliphatic polyester-chitosan composite fiber support comprises the following sequence and steps:

[0019] a. Aliphatic polyester and chitosan are dissolved in co-solvent, stirred evenly to obtain spinning solution, the total mass volume percentage of solute in spinning solution is 4%-25%, the mass fraction of chitosan in solute 9.1%-90%;

[0020] b. Put the spinning solution prepared in step a into a syringe with a needle inner diameter of about 1mm, and the needle of the syringe is connected to the positive pole of the power supply;

[0021] c. Use aluminum foil as the charging device, and ground it, place it opposite the needle, perpendicular to the needle of the glass syringe placed horizontally, and the horizontal distance between the two is 12-30cm;

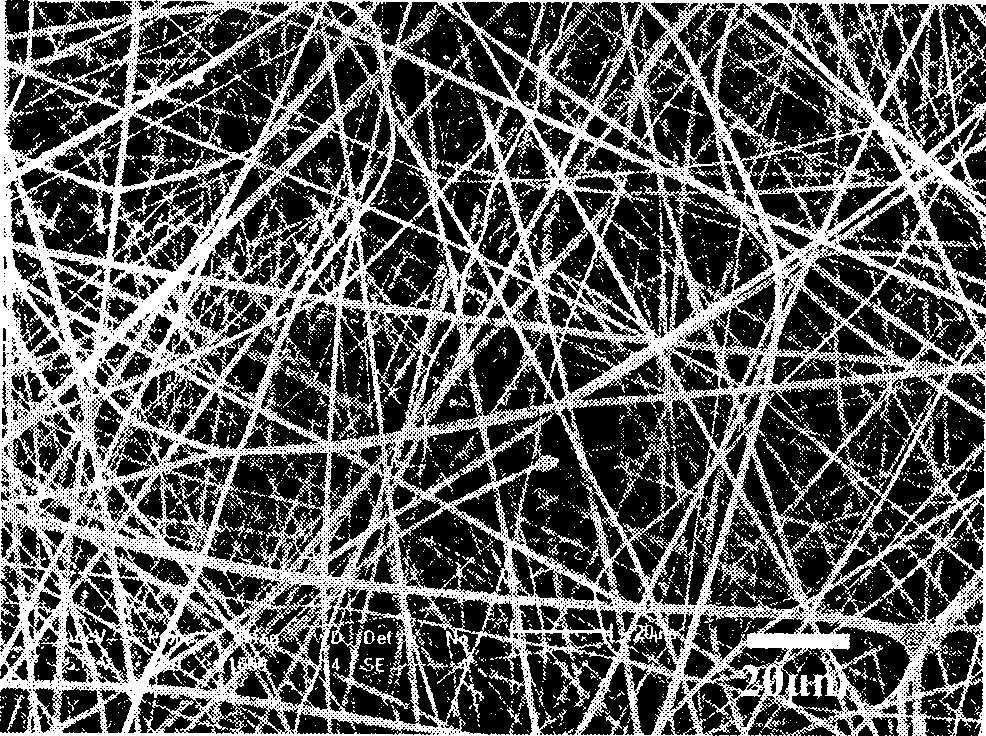

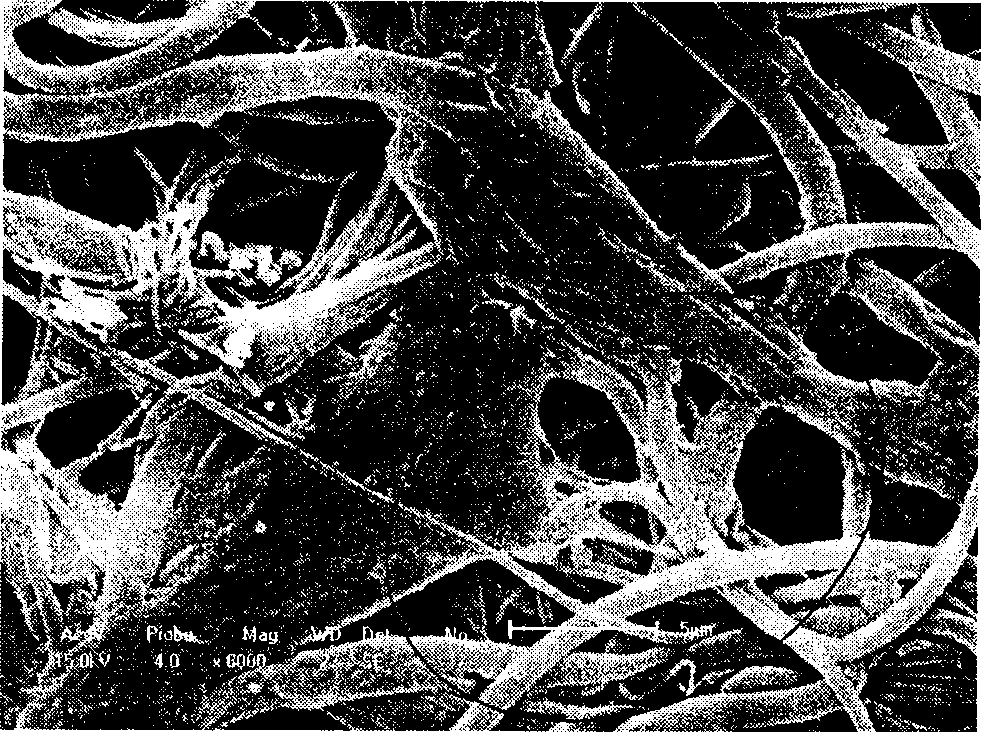

[0022] d. Adjust the voltage to 11-25KV. Under the high-voltage electric field, the polymer solution will be ejected from the needle and fly to the receiver. The solvent will volatilize duri...

Embodiment 1

[0026] 0.02g polylactic acid and 0.18g crab chitosan were added to a mixed solution (9:1 volume ratio) consisting of 4.5ml trifluoroacetic acid and 0.5ml methylene chloride, and stirred at room temperature for 24 hours. In the obtained spinning solution, the mass ratio of polylactic acid and crab chitosan is 1:9, and the total mass volume percentage of solute is 4%. The above-mentioned polymer solution is pumped into a glass syringe, and the inner diameter of the needle is about 1mm . Connect the needle of this syringe to the positive pole of the power supply providing a voltage of 14kV, and place it horizontally. Use aluminum foil as the receiver and place it at a horizontal distance of 12cm opposite the needle, perpendicular to the syringe, and grounded. Under the high-voltage electric field, the polymer solution will be ejected from the needle and fly to the receiver. The solvent will volatilize during the flight to form micro / nano fibers, and the fiber membrane scaffold w...

Embodiment 2

[0028] 0.18g of polycaprolactone and 0.18g of shrimp chitosan were added to 6.51ml of trifluoroacetic acid and stirred at room temperature for 24 hours. In the prepared spinning solution, the mass ratio of polylactic acid and shrimp chitosan is 1:1, and the total mass volume percentage of solute is 5.5%. The above polymer solution is pumped into a glass syringe, and the inner diameter of the needle is about 1mm. Connect the needle of this syringe to the positive pole of the power supply providing a voltage of 17kV, and place it horizontally. Use aluminum foil as the receiver and place it at a horizontal distance of 18cm opposite the needle, perpendicular to the syringe, and grounded. Under the high-voltage electric field, the polymer solution will be ejected from the needle and fly to the receiver. The solvent will volatilize during the flight to form micro / nano fibers, and the fiber membrane scaffold with an average diameter of 840nm will be received on the aluminum foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com