Method for preparing bionic extracellular matrix silk fibroin/chitosan composite nanometer fibre

A technology of composite nanofibers and silk fibroin, which is applied in the direction of spinning solution preparation, cellulose/protein conjugated artificial filament, fiber treatment, etc., can solve the problem of silk fibroin nanofibers being brittle, poor in flexibility, and unable to realize functions Biomimetic, reducing practical value and other issues, to achieve the effect of excellent mechanical properties and degradation behavior, simple and easy preparation method, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First add 100 grams of cocoons to 1 liter of 0.5% Na 2 CO 3 Boiling in an aqueous solution for 30 minutes, repeating the treatment three times, fully washing with distilled water, and drying in a drying oven at 45° C. to obtain degummed silk fibers. with CaCl 2 :C 2 h 5 OH:H 2 A ternary solvent was prepared with a molar ratio of O=1:2:8, and the silk fiber was hydrolyzed in a water bath at 70°C for 1 hour at a constant temperature at a bath ratio of 1:10 to obtain a completely dissolved brown-yellow silk fiber hydrolysis solution. Put the hydrolyzed solution into a dialysis bag, dialyze with distilled water for 72 hours, put the dialyzed silk fiber hydrolyzed solution into -80°C for 12 hours, and then freeze-dry it at -58°C until dry to obtain a white, odorless, loose porous solid silk fibroin.

Embodiment 2

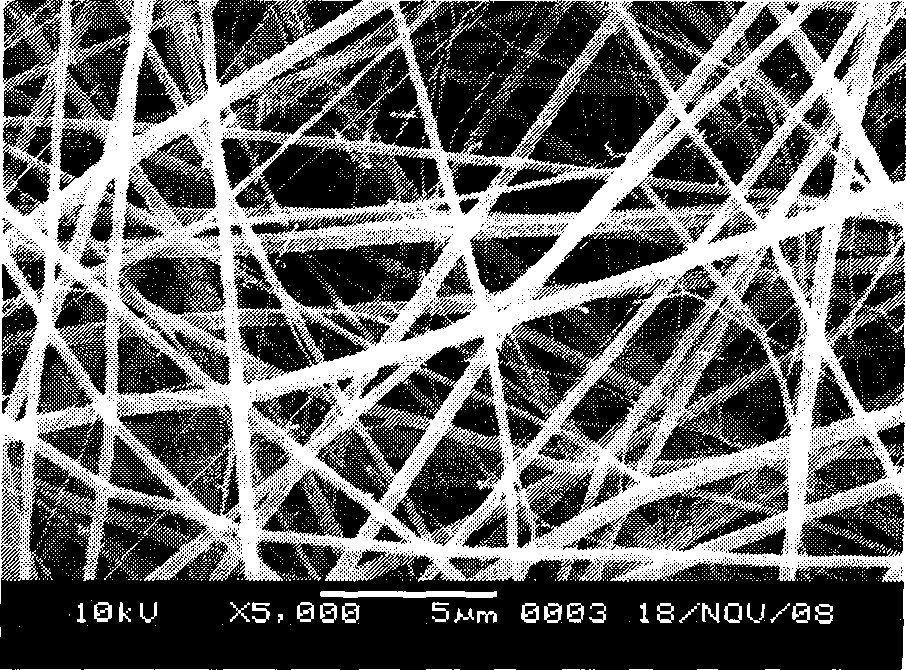

[0028] Dissolve 1.0 gram of silk fibroin in 10 milliliters of hexafluoroisopropanol, stir until fully dissolved to obtain a silk fibroin solution with a concentration of 10% (g / ml); 0.6 gram of chitosan is dissolved in 10 milliliters of In the hexafluoroisopropanol and the trifluoroacetic acid mixed solvent that ratio 90:10 mixes, stir until dissolving completely, obtain the chitosan solution that concentration is 6% (gram / milliliter); Two kinds of solutions are with volume ratio 12:5, The mass ratio of solute is mixed at 4:1, and the mixed solution is subjected to electrospinning, spinning conditions: voltage, 20 kV; electric field distance, 130 mm; spinning rate, 80 ml / hour, to obtain an average fiber diameter of 305 nanometers Composite nanofiber membrane.

Embodiment 3

[0030] Take by weighing 1.0 grams of silk fibroin prepared in Example 1, dissolve in 10 milliliters of hexafluoroisopropanol, stir until completely dissolved, and obtain a silk fibroin solution with a concentration of 10% (g / ml); Chitosan was dissolved in 10 milliliters of hexafluoroisopropanol and trifluoroacetic acid mixed solvent with a volume ratio of 90:10, stirred until fully dissolved to obtain a chitosan solution with a concentration of 6% (g / ml); the two The two solutions were mixed at a volume ratio of 3:5 and a solute mass ratio of 1:1, and the mixed solution was subjected to electrospinning, spinning conditions: voltage, 20 kV; electric field distance, 130 mm; spinning rate, 80 ml / hour , to obtain a composite nanofibrous membrane with an average fiber diameter of 202 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber diameter | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com