P-zinc oxide/N- nickel oxide heterogeneous PN junction ultraviolet laser diode and method for production

An ultraviolet laser, pn junction technology, applied in the field of nanomaterials and optoelectronic devices, can solve problems such as poor stability and low p-ZnO mobility, and achieve the effects of improving performance, improving luminescence performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] (3) Preparation of p-NiO: A Ni metal target with a diameter of 50 mm was used. According to reports by I.Hotovy et al. (I.Hotovy, J.Huran, J.Janíka, et al., Deposition and properties of nickel oxide films produced by DC reactive magnetron sputtering, Vacuum, 1998, 51 (2): 157.) , NiO film prepared by magnetron reactive sputtering, when O in the mixed atmosphere 2 When the ratio increases, the resistivity of the film will increase, while the light transmittance will decrease. In order to make the NiO film have high electrical conductivity and light transmittance at the same time, the relative oxygen partial pressure O 2 / (O 2 +Ar) = 50-70% of the optimal amount. The chamber background vacuum degree before sputtering is greater than 5×10 -4 Pa, the sputtering pressure is 0.5-1.5Pa, and the sputtering power is 100-250W. Before coating, pre-sputter for 10 min to remove impurities on the target surface. NiO film is plated on the substrate with ZnO thin film. The coatin...

Embodiment 1

[0026] 1. Substrate cleaning: Use n-type GaN grown on sapphire as the substrate, cut it into a size of 25mm×30mm, ultrasonically clean it with acetone, alcohol, and deionized water for 3 minutes, and finally dry it with a nitrogen gun.

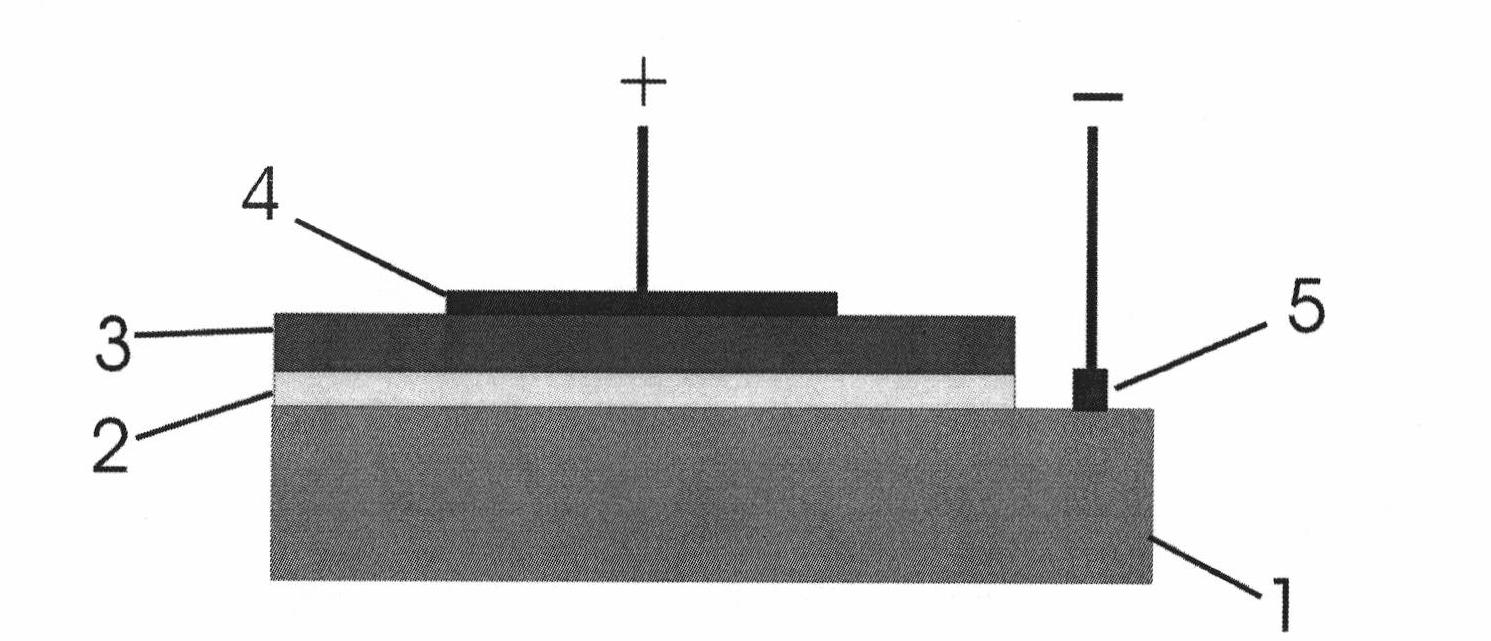

[0027] 2. Growth of n-type layer ZnO: Deposit ZnO thin film 2 on GaN 1 by radio frequency magnetron sputtering. The target material is ZnO ceramic target, and the background vacuum is 1*10 -3 Pa, deposition substrate temperature: 300°C; deposition pressure: 0.5Pa; relative oxygen partial pressure O 2 / (O 2 +Ar)=15%, power 150W; sputtering time: 15min.

[0028]3. Preparation of p-NiO: NiO film 3 was deposited on the ZnO nano film by reactive sputtering. The target material is made of high-purity metal Ni target, and the background vacuum is 4*10 -4 Pa, deposition substrate temperature: 150°C; deposition pressure: 1.5Pa, relative oxygen partial pressure O 2 / (O 2 +Ar)=50%; power: 100W, sputtering time: 80min.

[0029] 4. Electrode prepara...

Embodiment 2

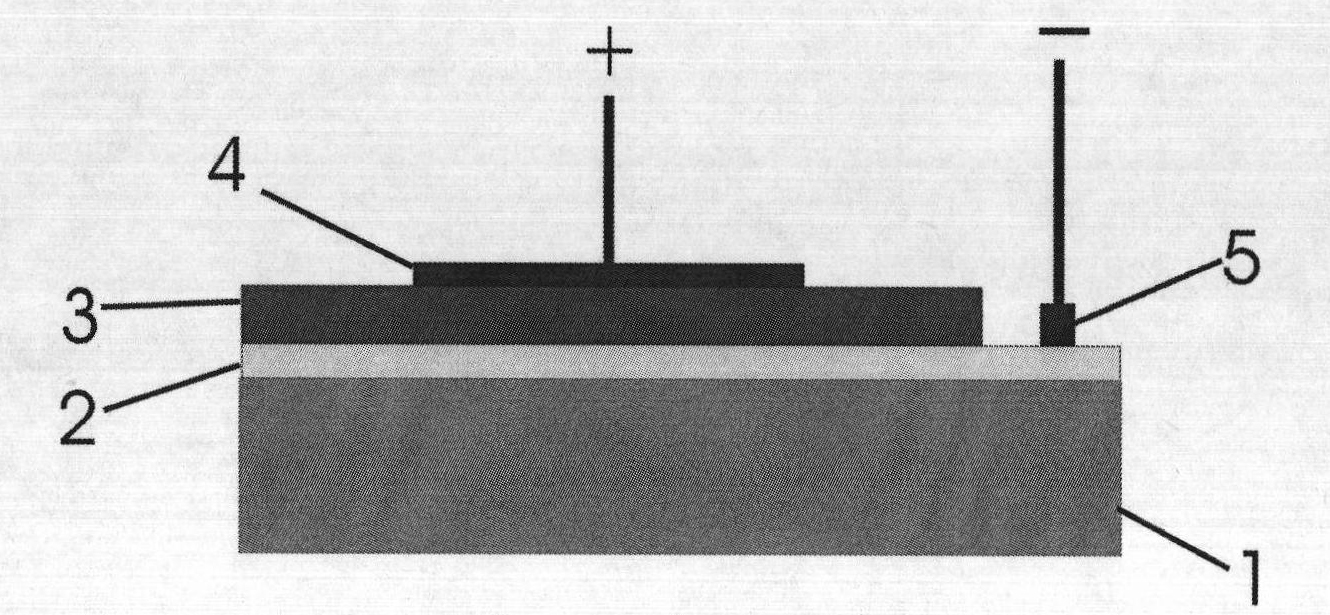

[0032] 1. Substrate cleaning: Use n-type GaN grown on sapphire as the substrate, cut it into a size of 25mm×30mm, ultrasonically clean it with acetone, alcohol, and deionized water for 3 minutes, and finally dry it with a nitrogen gun.

[0033] 2. Growth of the n-type layer: a ZnO thin film 2 is deposited on the GaN 1 by radio frequency magnetron sputtering. The target material is ZnO ceramic target, and the background vacuum is 8*10 -4 Pa, deposition substrate temperature: 100°C; deposition pressure: 5.0Pa; relative oxygen partial pressure O 2 / (O 2 +Ar)=40%, power 80W; sputtering time: 40min.

[0034] 3. Preparation of p-NiO: A NiO thin film 3 was deposited on a glass sheet with ZnO nanorods by reactive sputtering. The target material is high-purity metal Ni target, and the background vacuum is 5*10 -4 Pa, deposition substrate temperature: 400°C; deposition pressure: 0.5Pa, relative oxygen partial pressure O 2 / (O 2 +Ar)=70%; power: 250W, sputtering time: 30min.

[00...

PUM

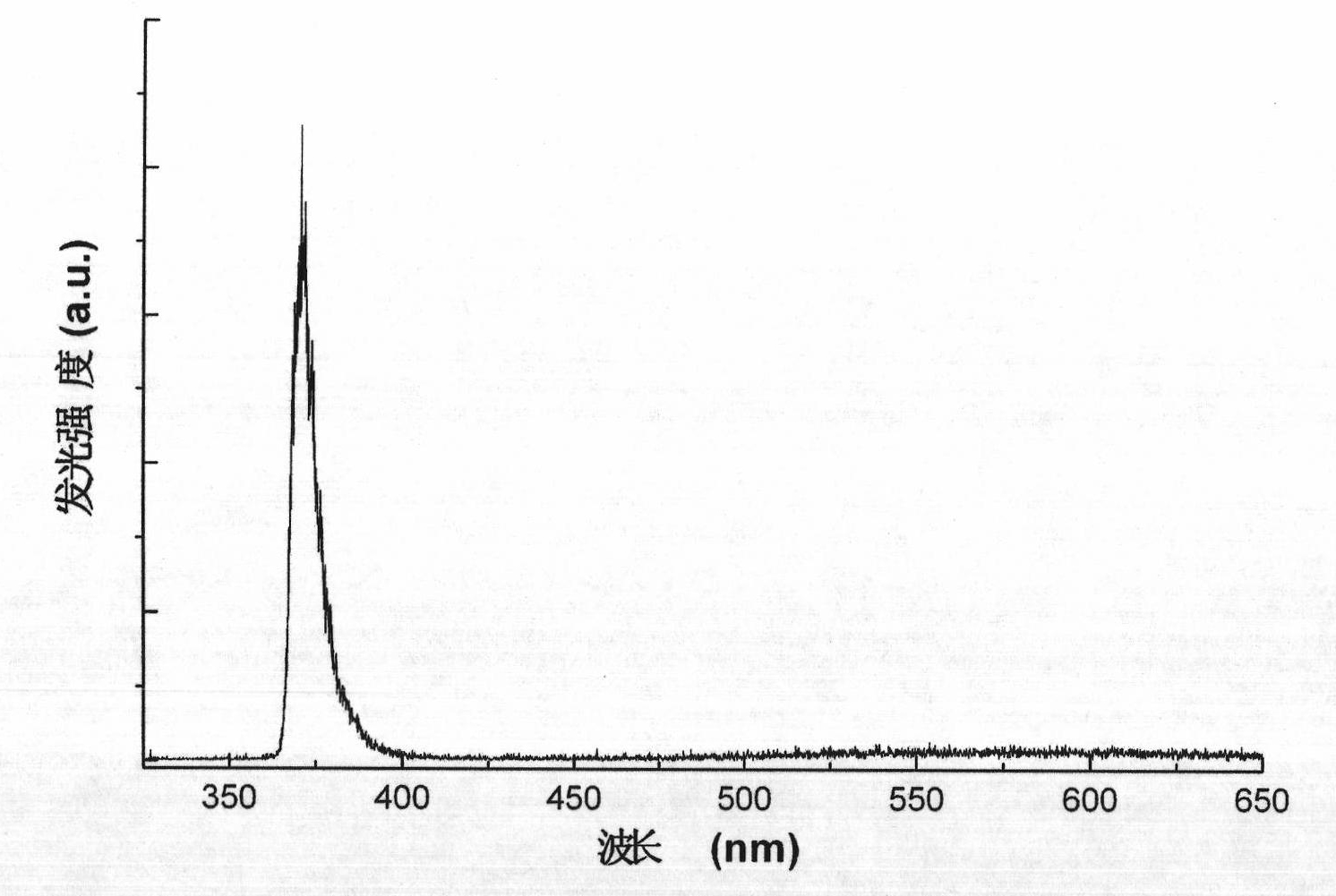

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com