Surface-modified iron oxide magnetic nano-particle and surface modification method thereof

A magnetic nanoparticle and surface modification technology, which is applied in the field of iron oxide magnetic nanoparticle and its surface modification, to achieve the effects of easy promotion and industrial production, simple process and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

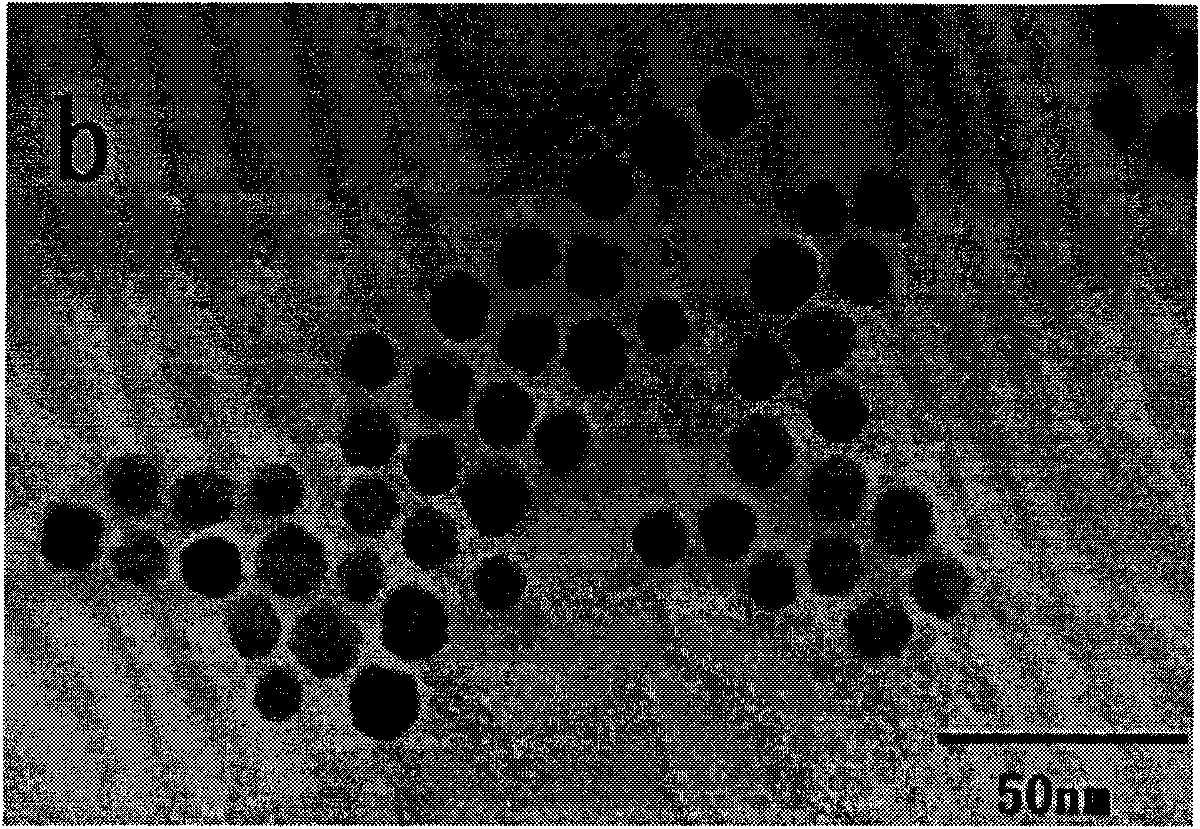

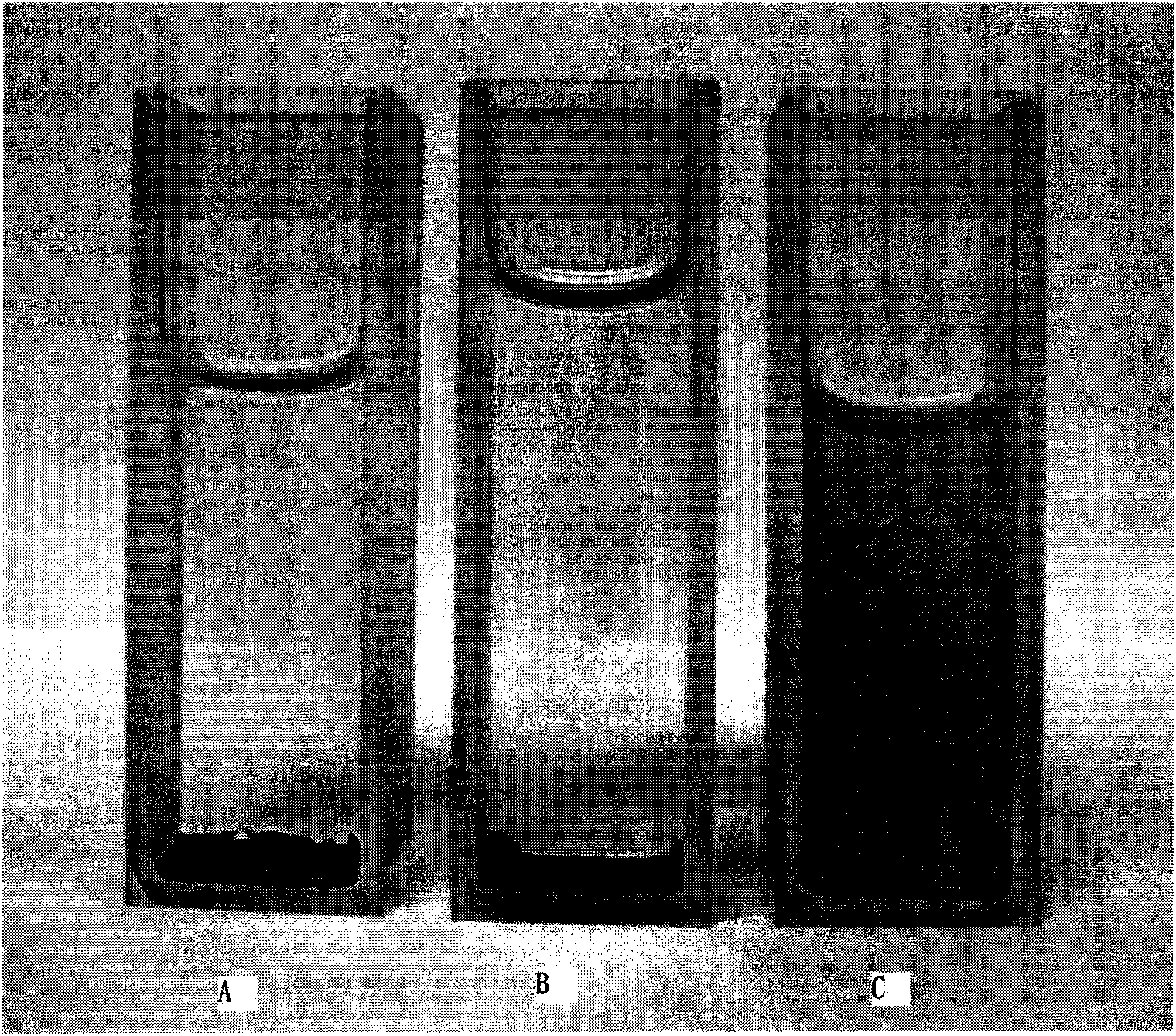

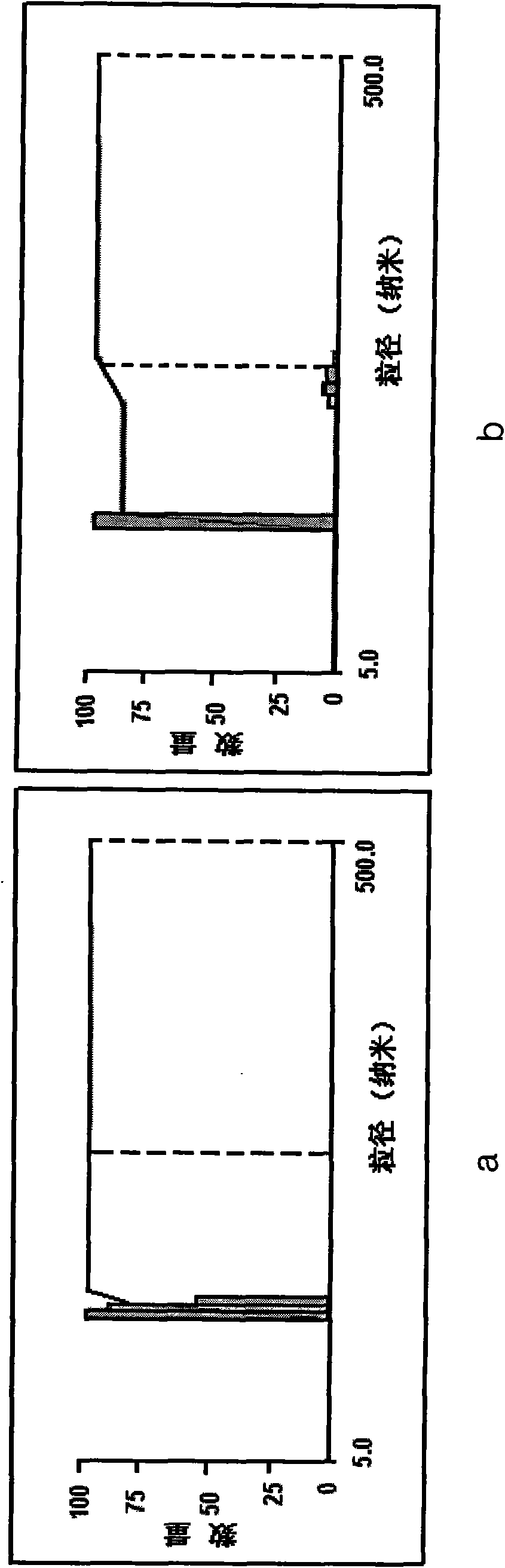

Image

Examples

Embodiment 1

[0028] This embodiment prepares iron oxide magnetic nanoparticles with oleic acid, and the process steps are as follows:

[0029] (1) Add 1000mg of iron triacetylacetonate to 50ml of octyl ether containing 5% (volume percent) oleic acid under nitrogen protection, heat to 300°C and reflux for 0.5 hours, wait for the reaction mixture to cool to room temperature, and use a syringe Extract 2% (volume percentage) of the reaction mixture from the system for preservation.

[0030] (2) Add trimethylamine oxynitride to the reaction mixture, the amount of trimethylamine oxynitride is 10% of the volume of the reaction mixture, and after being heated to 120°C for 1 hour under the protection of nitrogen, the temperature is raised to 10°C / min. Reflux at 300°C for 2 hours, then lower the temperature of the system to 100°C, inject the reaction mixture taken out in step (1) into the system, heat to 300°C and reflux for 2 hours, cool to room temperature, add 50ml of ethanol and ultrasonically s...

Embodiment 2

[0032] In this embodiment, the iron oxide magnetic nanoparticles with oleic acid prepared in Example 1 are surface-modified, and the process steps are as follows:

[0033] (1) Surface aldylation of iron oxide magnetic nanoparticles with oleic acid

[0034] 50 mg of iron oxide magnetic nanoparticles with oleic acid prepared in Example 1, 10 ml of cyclohexane, 0.05 mg of osmium tetroxide (prepared into an aqueous solution with a mass concentration of 1% with deionized water), and 10 mg of sodium perchlorate.

[0035] Disperse the iron oxide magnetic nanoparticles with oleic acid in cyclohexane at room temperature and normal pressure, then add osmium tetroxide aqueous solution and sonicate for 10 minutes, then add sodium perchlorate and sonicate for 0.5 hours, followed by magnetic stirring After 3 hours, the magnetic separation was carried out after the magnetic stirring was completed, and the magnetic iron oxide magnetic nanoparticles on the surface obtained by the magnetic sepa...

Embodiment 3

[0040] In this embodiment, the iron oxide magnetic nanoparticles with oleic acid prepared in Example 1 are surface-modified, and the process steps are as follows:

[0041] (1) Surface aldylation of iron oxide magnetic nanoparticles with oleic acid

[0042] 200 mg of iron oxide magnetic nanoparticles with oleic acid prepared in Example 1, 40 ml of hexane, 2 mg of chromium trioxide (prepared as an aqueous solution with a mass concentration of 10% with deionized water), and 50 mg of potassium periodate.

[0043] Disperse the iron oxide magnetic nanoparticles with oleic acid in hexane at room temperature and normal pressure, then add chromium trioxide aqueous solution and sonicate for 50 minutes, then add potassium periodate and sonicate for 2 hours, then magnetically stir for 5 minutes hour, magnetic separation is carried out after the magnetic stirring ends, and the iron oxide magnetic nanoparticles on the surface of the magnetic separation obtained are washed 4 times with deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com