Method for producing lithium iron phosphate without inert gas protection

A lithium iron phosphate, inert gas technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as low tap density, polluted finished products, and increased pressure, achieve stable charge and discharge performance, and reduce production. The effect of low cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

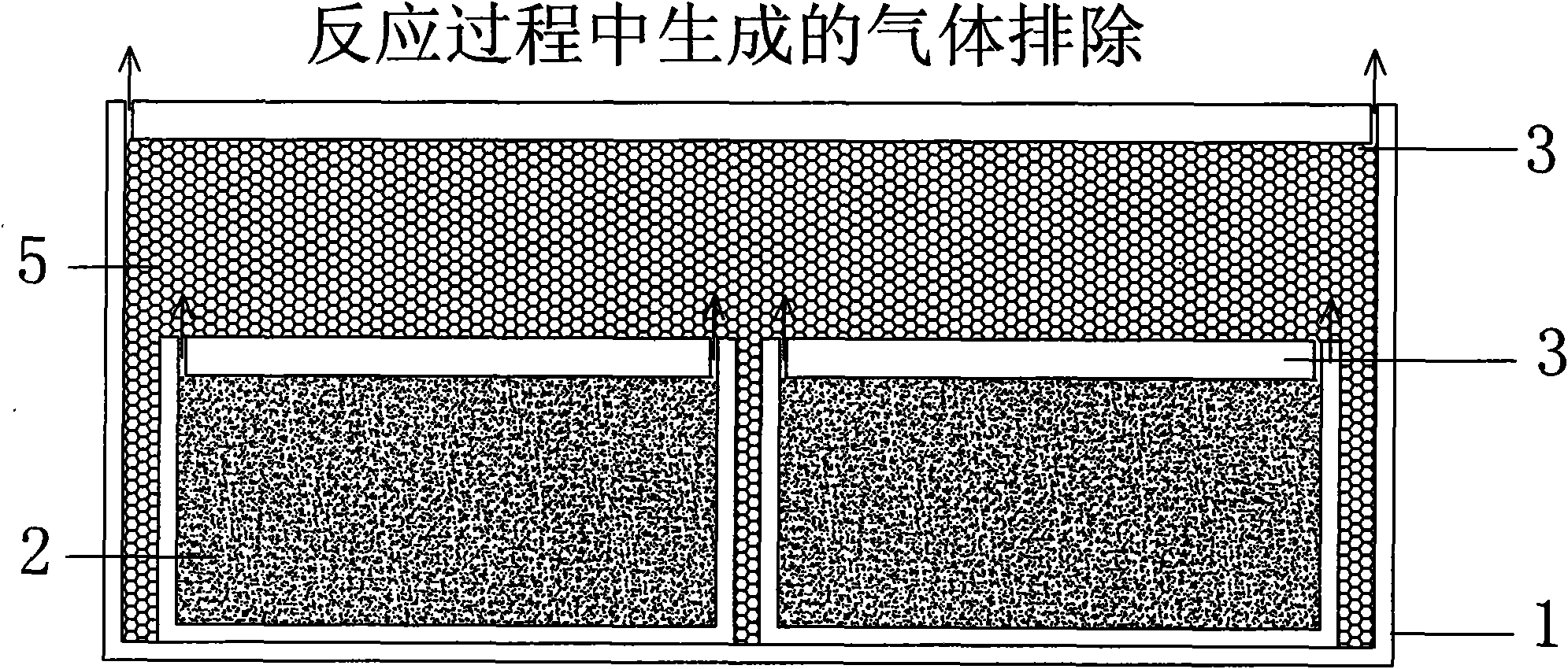

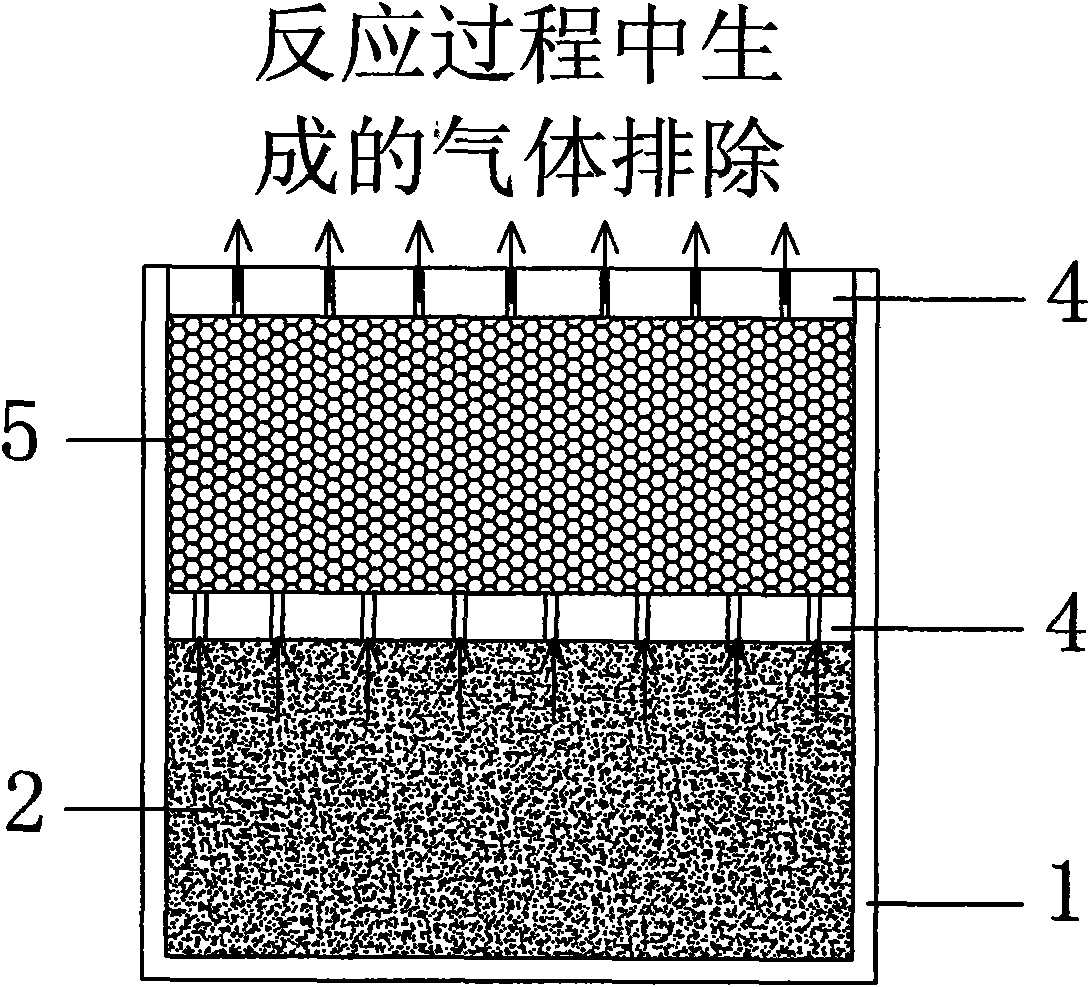

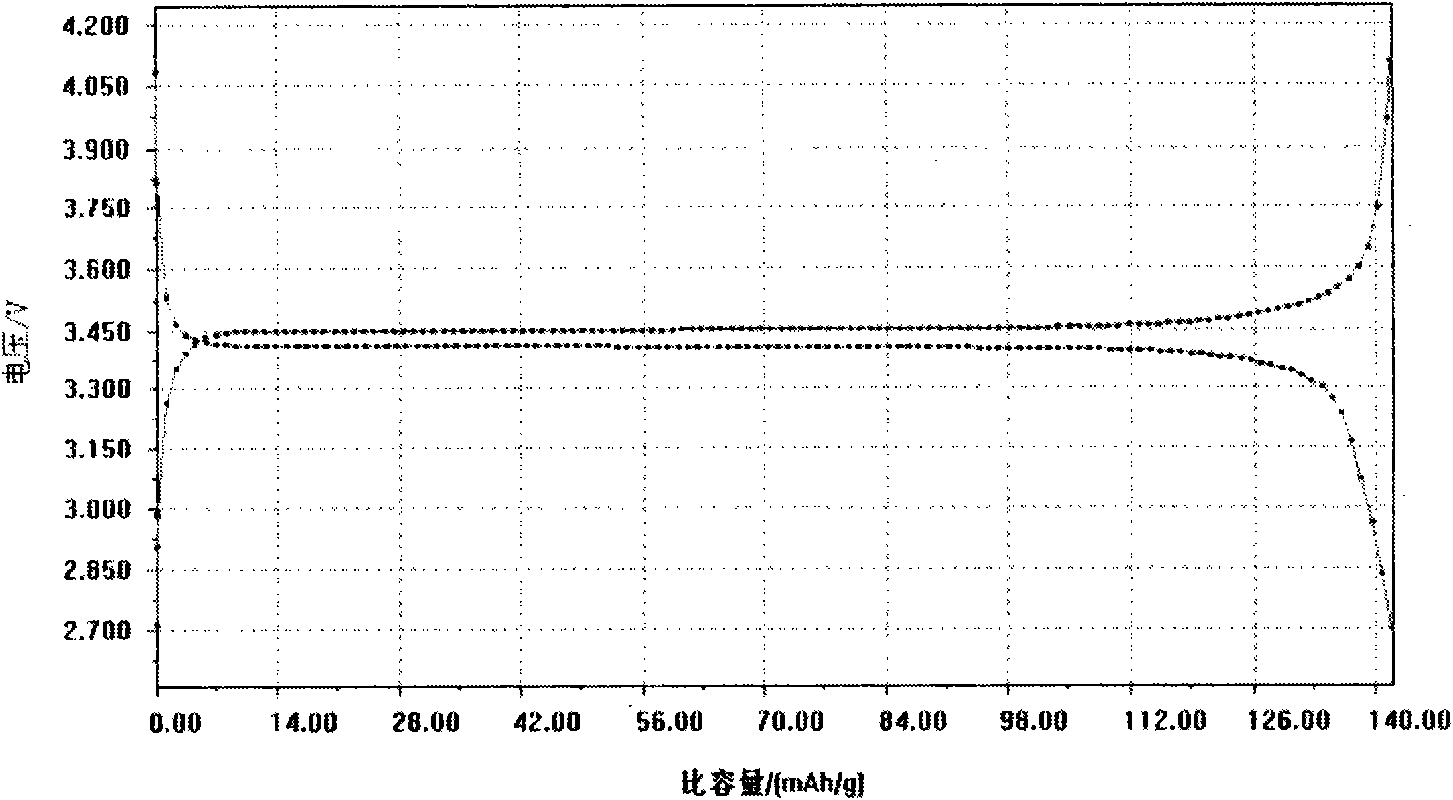

[0042] Lithium hydroxide: ferrous oxalate: ammonium dihydrogen phosphate is mixed in a molar ratio of 1.1:1:1, and 5% carbon black is added in a mass ratio, placed in a stirring ball mill for 5 hours; fully mixed and ground to prepare Put the precursor body into a stainless steel box, compact the precursor powder with a hydraulic press, cover with a porous stainless steel plate and spread a stainless steel screen with a pore size of less than 100 mesh, put in activated carbon powder larger than 100 mesh and cover with a porous stainless steel plate, Then put it in a vacuum box to evacuate for 0.5 hours, then fill it with high-purity nitrogen, and finally send the precursor into the tunnel kiln for roasting, start heating from room temperature, and the heating rate is 10 °C / min, after heating to 650 °C, roast for 8 hour, and then cooled to room temperature with the furnace, the obtained lithium ferrous phosphate gram capacity is 141mAh / g, and its charge and discharge curve is as...

Embodiment 2

[0044] Lithium carbonate: ferrous oxalate: ammonium dihydrogen phosphate: Mg(OH) 2 Mix at a molar ratio of 0.5:0.95:1:0.05, add 8% glucose by mass ratio, place in a stirring ball mill for mixing and grinding for 5 hours; put the precursor prepared by fully mixing and grinding into a stainless steel box, and use a hydraulic press Compact the precursor powder, cover with a porous stainless steel plate and spread a stainless steel screen with a pore size of less than 100 mesh, put in activated carbon powder larger than 100 mesh, cover with a porous stainless steel plate, and then vacuumize in a vacuum box for 0.5 hours before charging Inject high-purity nitrogen, and finally send the precursor into a tunnel kiln for calcination, start heating from room temperature at a heating rate of 10°C / min, heat to 650°C and then calcine for 8 hours, then cool to room temperature with the furnace, the obtained product The XRD diffraction pattern of Figure 4 As shown, by comparing with the s...

Embodiment 3

[0046] Lithium carbonate and iron phosphate were mixed in a molar ratio of 0.5:1, and 10% glucose was added in a mass ratio, and placed in a stirring ball mill for mixing and grinding for 5 hours; the precursor prepared by fully mixing and grinding was loaded into a stainless steel box, Compact the precursor powder with a hydraulic machine, cover with a porous stainless steel plate and spread a stainless steel screen with a pore size of less than 100 mesh, put in activated carbon powder with a diameter of more than 100 mesh and cover with a porous stainless steel plate, and finally send the precursor into the tunnel kiln Carry out calcination, start heating from room temperature, the heating rate is 10 ℃ / min, after heating to 700 ℃, calcine for 6 hours, then cool to room temperature with the furnace, the gram capacity of the obtained lithium ferrous phosphate is 157mAh / g, and its charge and discharge curve is as follows Image 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com