Electrochemical ultra-micro compound electrode and preparation method thereof

A combined electrode and ultra-micro electrode technology, applied in chemical instruments and methods, material electrochemical variables, gaseous chemical plating, etc., can solve the problems of limiting the miniaturization of combined electrodes, fine preparation and manipulation of micro probes, and difficult to control. , to achieve the effect of accurate and controllable exposure area, accurate and controllable electrode exposure area, and good trace detection capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

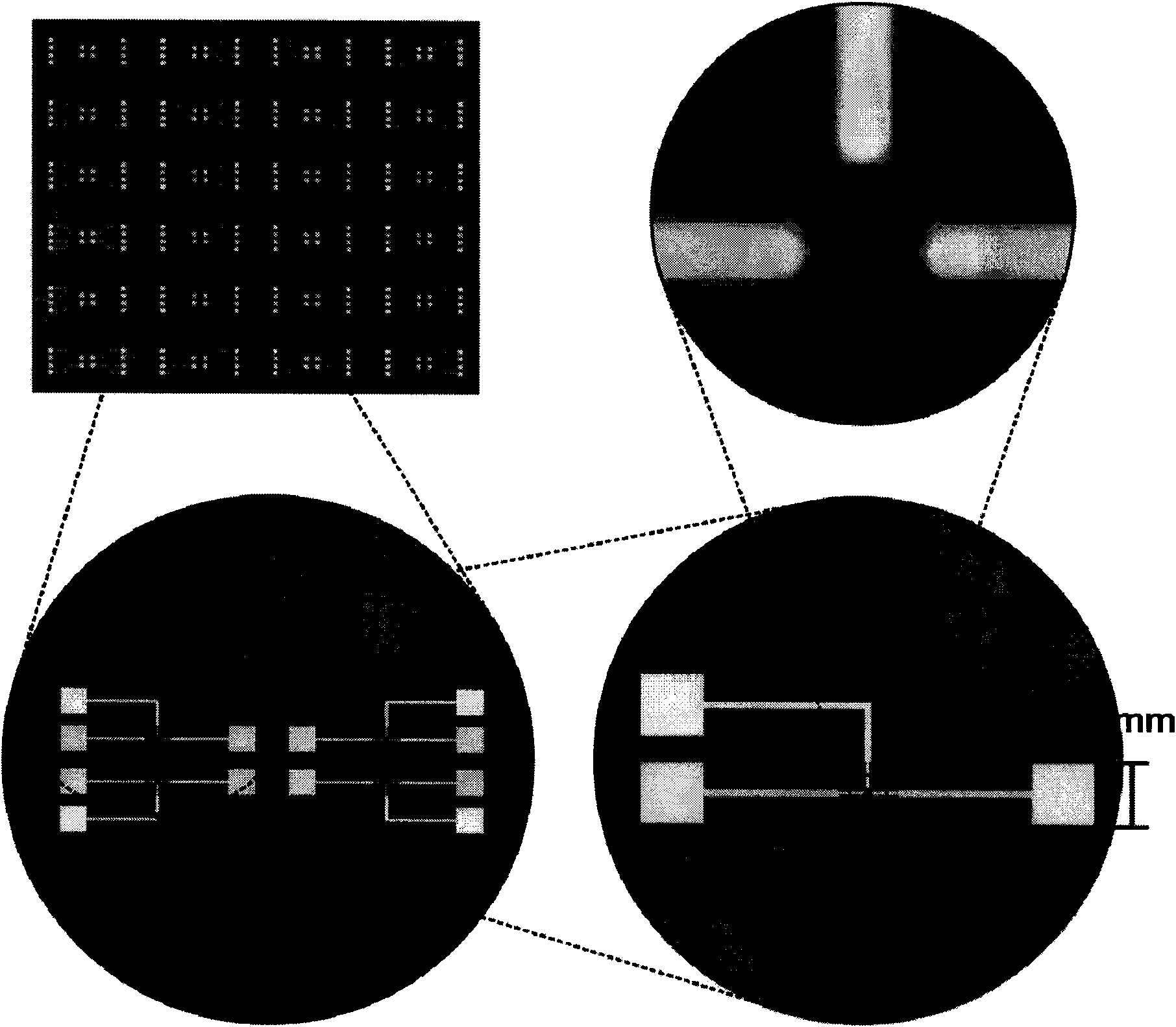

[0040] Example 1. Preparation of three-terminal ultramicro composite electrode by ultraviolet lithography

[0041] The three-terminal ultramicro composite electrode includes a pair of gold electrodes as working electrodes and counter electrodes respectively, and silver electrodes as quasi-reference electrodes.

[0042] In the experiment, the lithography operation used the MA6 lithography machine of the German Suss company; the metal evaporation used the Johnsen electron beam evaporation system; the substrate was highly doped n-type silicon, and a layer of 500nm thick dioxide Silicon insulating layer; the photoresist is AZ 5214 photoresist, and the developer is AZ 351 stock solution.

[0043] The specific production steps are as follows:

[0044]1. Design template. The schematic diagram of the device design of the ultramicro composite electrode is shown in figure 1 shown. Each device consists of a pair of gold electrodes and a silver electrode with three terminals, as shown...

Embodiment 2

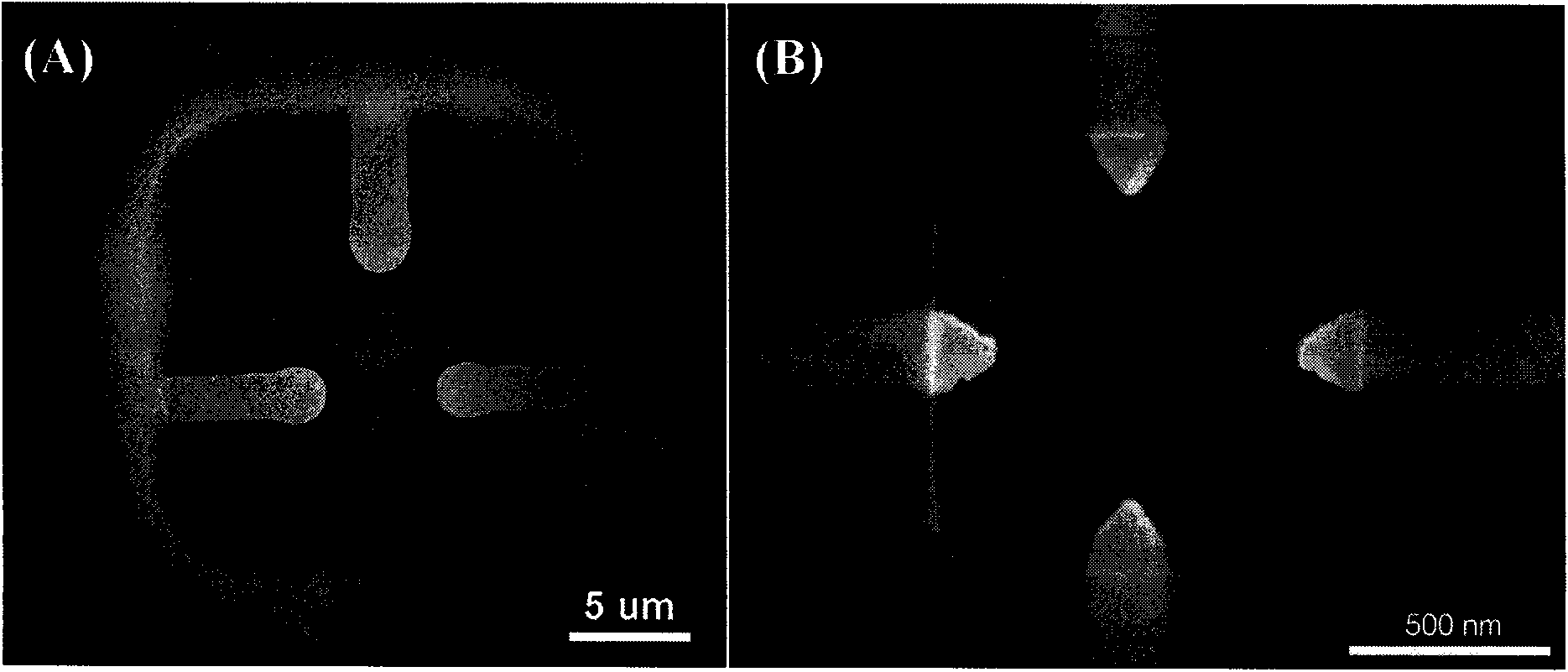

[0060] Example 2, preparation of four-terminal ultramicro composite electrode by electron beam lithography

[0061] The preparation process of the four-terminal ultramicro composite electrode is basically the same as that of the three-terminal. The biggest difference is that the electron beam lithography technology replaces the ultraviolet lithography process to complete the electrode pattern transfer and form the micro-electrolytic cell, without the need for a mask. The design of the four-terminal electrodes is based on the fact that the electron beam lithography operation is more complicated and the structure is finer, so as to avoid the failure of the entire device due to the failure of one end electrode.

[0062] Spin-coat EP50G (JSR corp.) / PMGI (Micro Chem inc.) double-layer photoresist (theoretically single-layer photoresist is also possible, because the electrodes in this embodiment are very fine, double-layer photoresist is to improve the preparation The success rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com