Visible light response composite photocatalyst and preparation method thereof

A catalyst and composite light technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low hydrogen production rate, difficulty in utilizing visible light, increase in hydrogen production rate, and decrease in photocatalytic efficiency. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

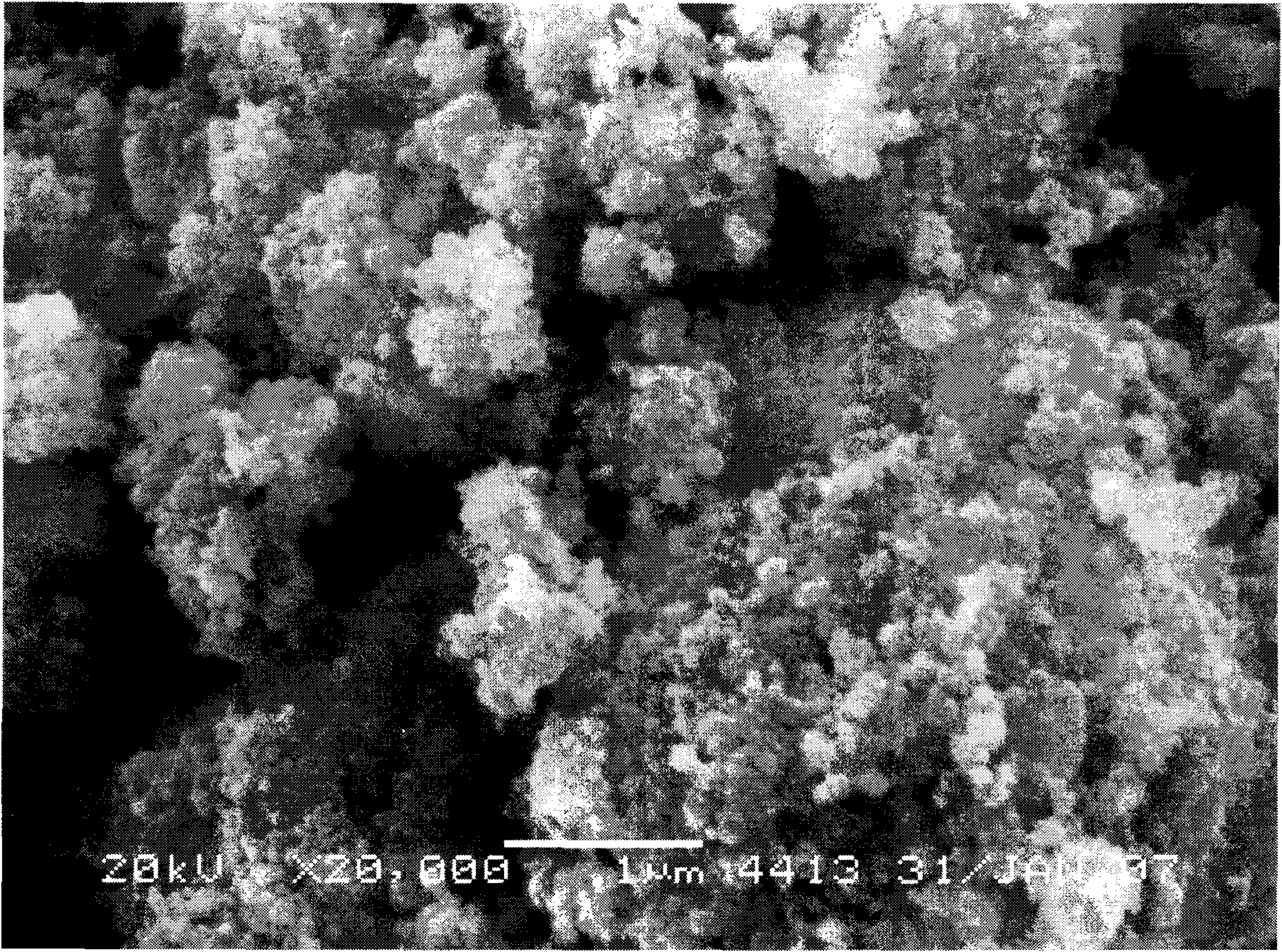

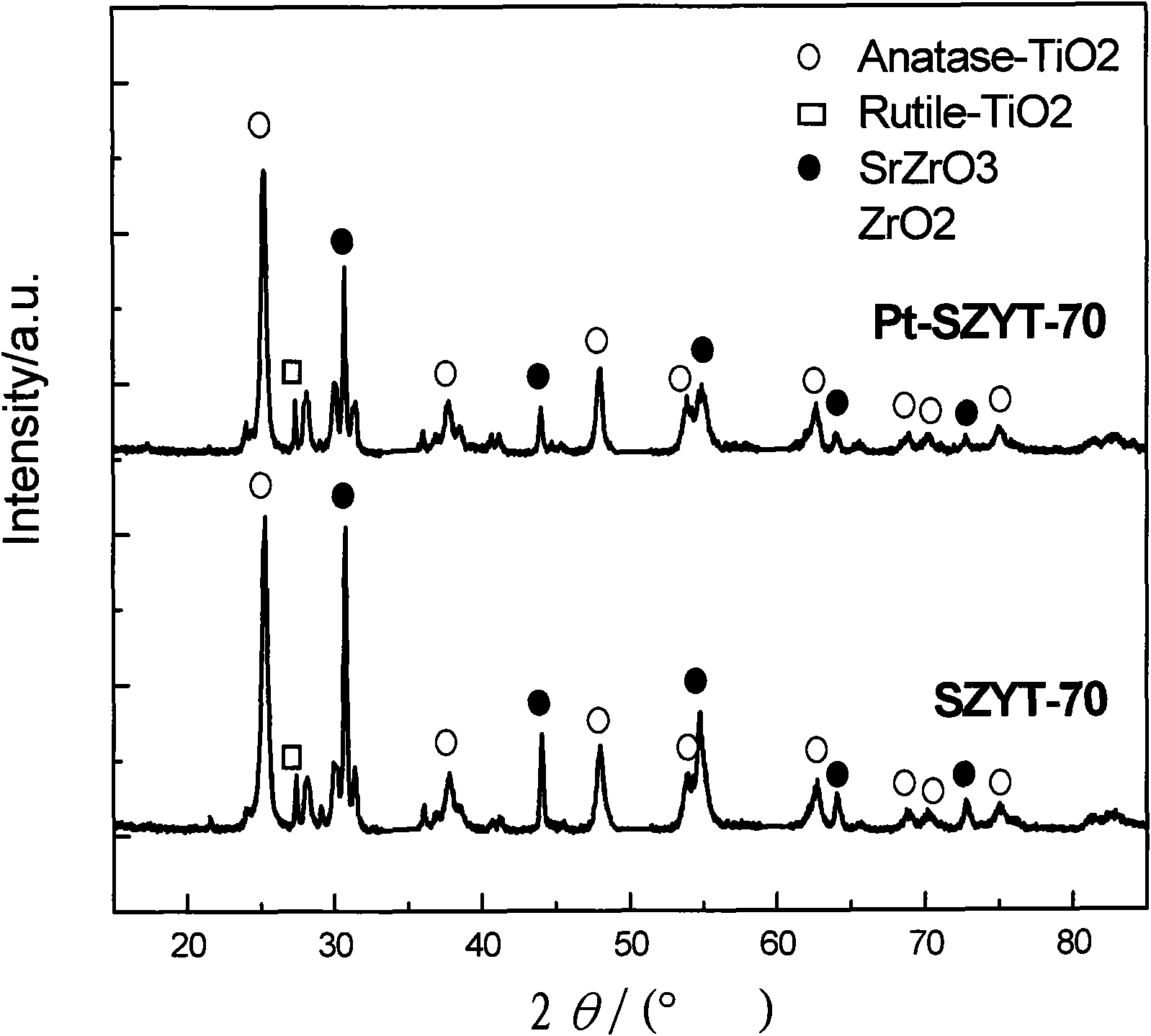

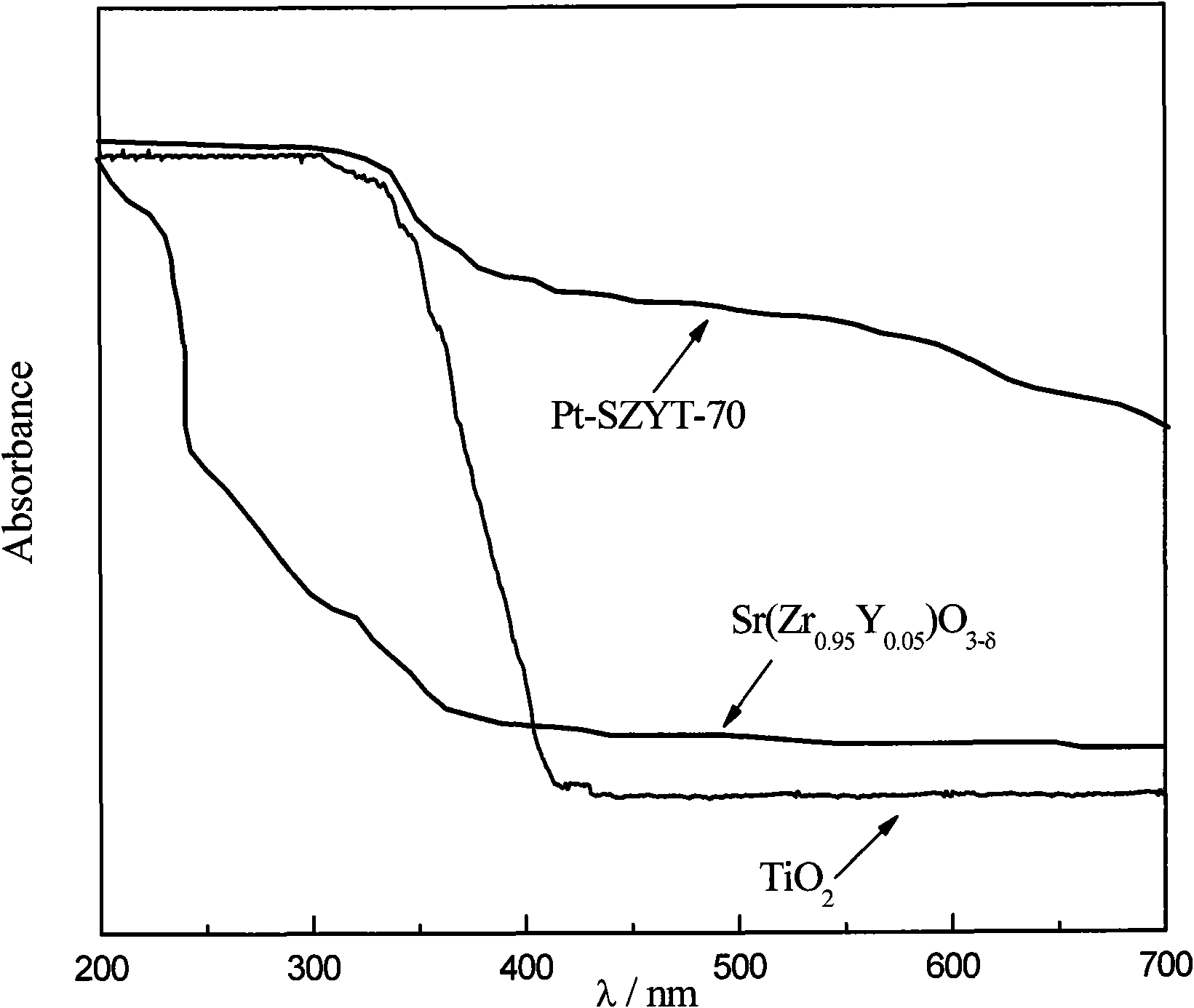

[0019] to 0.2mol·L -1 Slowly add 0.1mol L to the sodium oxalate solution -1 Zirconium oxychloride, and keep stirring, get clear Na 2 ZrO(C 2 o 4 ) 2 solution. At room temperature, an equal amount of Sr(NO 3 ) 2 solution with freshly prepared Na 2 ZrO(C2 o 4 ) 2 The solutions are mixed to obtain white SrZrO(C 2 o 4 ) 2 Precipitation, SrZrO(C 2 o 4 ) 2 After precipitation filtration, successively use hot water, 10wt% ZrOCl 2 The solution was washed with distilled water and acetone, and then dried at 70° C., and the dried product was calcined at 900° C. for 5 hours to obtain strontium zirconate. Take 0.007 mole of yttrium oxide powder and 0.10 mole of strontium zirconate powder and grind them thoroughly in an agate mortar, mix them evenly, press into tablets, and calcinate at 1250°C for 1 hour (repeated three times), to obtain a photocatalyst with yttrium doping amount of 7%. Get 10 grams of yttrium-doped strontium zirconate and 90 grams of TiO 2 Mix and grind t...

Embodiment 2

[0021] The method of Example 1 was adopted to obtain strontium zirconate. Take 0.005 mole of yttrium oxide powder and 0.10 mole of strontium zirconate and grind them thoroughly in an agate mortar, mix them evenly, press them into tablets, and calcinate at 1250°C for 1 hour (repeated three times), to obtain a product with 5% yttrium-doped strontium zirconate . Get 20 grams of 5% yttrium-doped strontium zirconate and 80 grams of TiO 2 Mix and grind thoroughly, then sinter at 700°C for 1 hour, take out the product and lightly grind it, and the product is marked as SZYT-80, which is used as the catalyst substrate before platinum loading. 10 grams of SZYT-70 were dispersed in 50 mL of methanol solution containing 0.040 grams of chloroplatinic acid (V H2O :V MeOH =99:1) for 15 minutes of ultrasonication, continued stirring for 30 minutes, and then directly irradiated with a 250W high-pressure mercury lamp for 10 hours under a nitrogen atmosphere. The photoreduction reaction of c...

Embodiment 3

[0023] The method of Example 1 was adopted to obtain strontium zirconate. Take 0.005 mol of yttrium oxide powder and 0.10 mol of strontium zirconate in an agate mortar, grind them well, mix them evenly, press into tablets, and calcinate at 1250°C for 1 hour (repeated three times), to obtain a photocatalyst with 5% yttrium doping. Get 30 grams of yttrium-doped strontium zirconate and 70 grams of TiO 2 Mix and grind thoroughly, then sinter at 700°C for 1 hour, take out the product and lightly grind it, and the product is marked as SZYT-70, which is used as the catalyst substrate before platinum loading. 10 grams of SZYT-70 were dispersed in 50 mL of methanol solution containing 0.090 grams of chloroplatinic acid (V H2O :V MeOH =99:1) for 15 minutes of ultrasonication, continued stirring for 30 minutes, and then directly irradiated with a 250W high-pressure mercury lamp for 10 hours under a nitrogen atmosphere. The photoreduction reaction of chloroplatinic acid occurs, and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com