Method for preparing high-quality large silicon carbide single crystal and silicon carbide single crystal prepared by same

A silicon carbide single crystal, high-quality technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the difficult problem of achieving defect-free, high-quality single polytype silicon carbide single Meet the problems of stable growth of high-quality large SiC single crystal, uniformity of temperature distribution in the radial direction of difficult-to-seed crystal, and achieve the effects of single crystal form, strong binding force, and improved temperature field uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A modified phenolic resin is used to bond 6H-SiC seed crystals to grow 6H-SiC single crystals.

[0041] This example is implemented according to the preferred implementation in the content of the invention:

[0042] In step (1), the resin is a phenolic resin modified with salicylaldehyde and resorcinarenes calixarene;

[0043] In step (2), the seed crystal adopts (0001) 6H-SiC with Si surface;

[0044] In step (3), heat to 180°C for thermal curing, and form a highly cross-linked three-dimensional network resin structure after curing, which can firmly and densely bond the 6H-SiC seed crystal and the seed crystal frame together;

[0045] In step (6), in an argon atmosphere, the temperature is increased at a certain heating rate (generally less than 10°C / h), and then gradually heated to 1200°C, slowly pyrolyzed and carbonized, and the resin residual carbon rate is 73%;

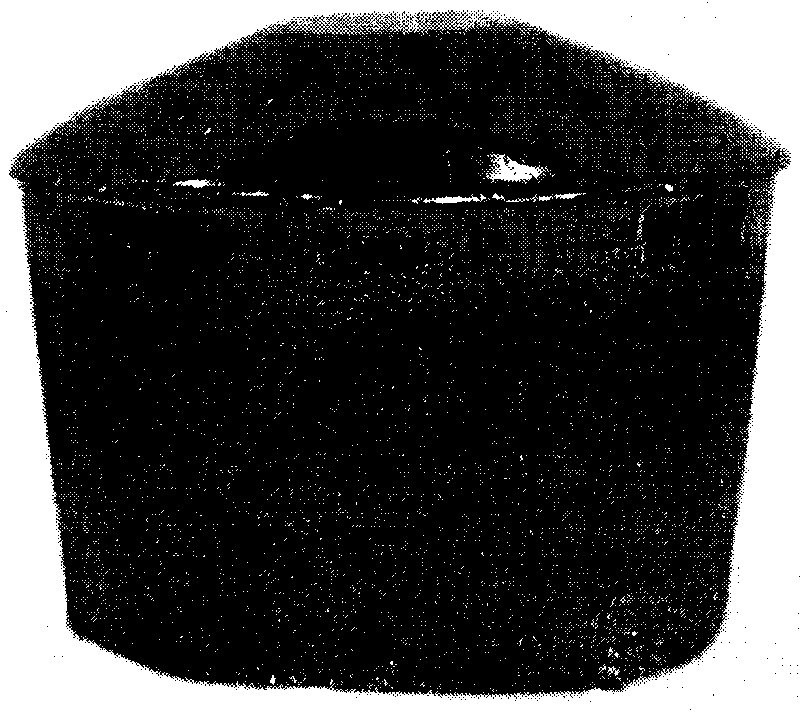

[0046] In step (7), the carbonized and bonded 6H-SiC seed crystal and the seed crystal frame are placed in a graph...

Embodiment 2

[0049] Adopt modified furfurone resin to bond 4H-SiC seed crystal to grow 4H-SiC single crystal.

[0050] This example is implemented according to the preferred implementation in the content of the invention:

[0051] In step (1), the resin adopts the modified furfurone resin formed by the condensation of cyclohexanone, urea, formaldehyde and furfuryl alcohol. The first step is the synthesis of ketone-aldehyde resin, the second step is the synthesis of aldehyde resin, and the third step It is the polycondensation of furfurone resin to obtain modified furfurone resin;

[0052] In step (2), the seed crystal adopts (0001) carbon surface 4H-SiC;

[0053] In step (3), heat to 150°C for thermal curing, and form a highly cross-linked three-dimensional network resin structure after curing, which can firmly and densely bond the 4H-SiC seed crystal and the seed crystal frame together;

[0054] In step (6), in a nitrogen atmosphere, the temperature is increased at a certain heating rate (generall...

Embodiment 3

[0058] The 15R-SiC seed crystal is bonded with modified epoxy resin to grow 15R-SiC single crystal.

[0059] This example is implemented according to the preferred implementation in the content of the invention:

[0060] In step (1), the resin is an epoxy resin modified with cyanate resin;

[0061] In step (2), the seed crystal adopts 15R-SiC with (0001) silicon surface;

[0062] In step (3), heat to 250°C for thermal curing, and form a highly cross-linked three-dimensional network resin structure after curing, which can firmly and densely bond the 15R-SiC seed crystal and the seed crystal frame together;

[0063] In step (6), in a nitrogen atmosphere, the temperature is increased at a certain heating rate (generally less than 7°C / h), and gradually heated to 800°C, slowly pyrolyzed and carbonized, and the resin residual carbon rate is 65%;

[0064] In step (7), the carbonized and bonded 15R-SiC seed crystal and the seed crystal frame are placed in a graphite crucible filled with raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com