Bacillus subtilis and application thereof in biocatalysis production of niacinamide

A Bacillus subtilis and biocatalysis technology, applied to Bacillus subtilis and its application field in biocatalytic production of nicotinamide, can solve problems such as difficulty in obtaining high-concentration products, decrease in reaction speed, decrease in enzyme activity, etc., and achieve accumulation of The effect of time reduction, maintenance of activity, and high total enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

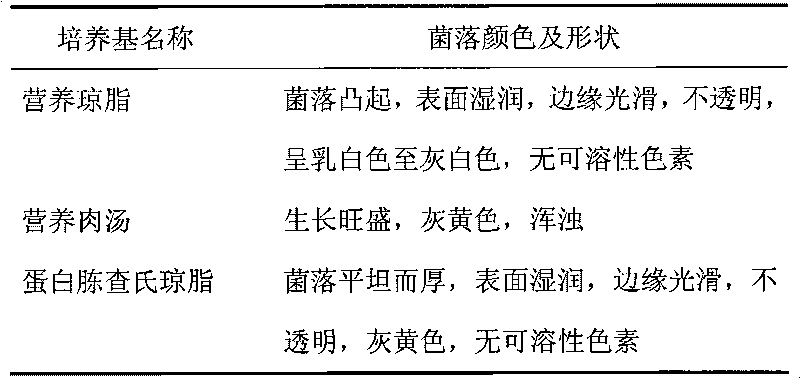

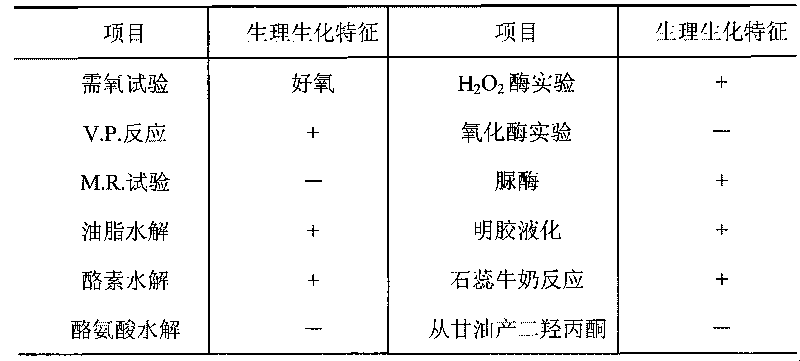

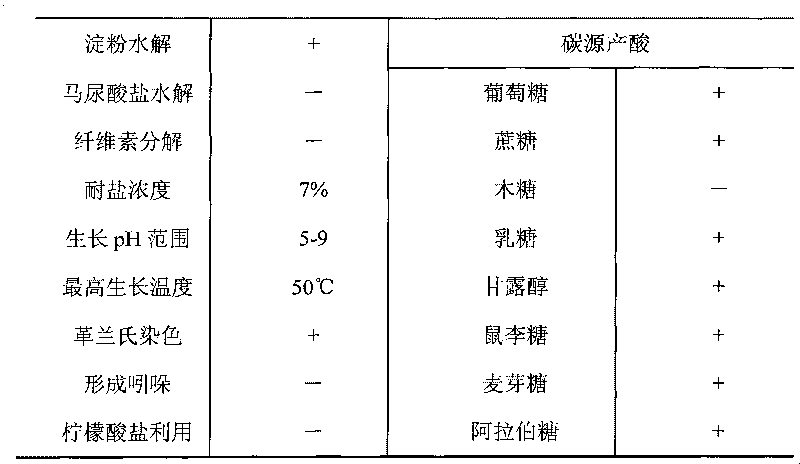

[0043] Example 1 Screening of Bacillus subtilis (Bacillus subtilis) CGMCC NO.3242

[0044] More than 100 batches of sludge samples were taken from different angles of the sewage pool of Nanjing No. 1 Pesticide Factory, and screened and identified after enrichment and cultivation in batches:

[0045] Weigh 10 grams of sludge, add 50 mL of sterile water, shake it with glass beads, inoculate 5 mL of the suspension into 45 mL of enrichment medium, place on a shaker at 30°C, and shake at 120 rpm for 3 days. Afterwards, the culture solution was taken for gradient dilution, and 10 -6 、10 -7 、10 -8 Gradient dilutions were spread on the plate containing the first screening solid medium, and cultured in a constant temperature incubator at 30°C for 3 to 6 days. Pick the grown single colony and inoculate it on the new primary screening solid medium for expanded culture, and the culture conditions are the same as above. After the bacteria grow out, scrape 3 to 5 rings and inoculate the...

Embodiment 2

[0050] The preparation of embodiment 2 biocatalysts

[0051] Inoculate the slant strain of Bacillus subtilis KR2 (CGMCC No.3242) into the liquid seed medium (glucose: 15, yeast extract: 5, peptone: 5, sodium chloride: 2, potassium dihydrogen phosphate: 1, hydrogen phosphate Dipotassium: 1, magnesium sulfate: 0.5, urea: 10, caprolactam: 5, cobalt chloride: 10ppm, pH 7.0, unit: g / L). At a temperature of 25°C and a rotating speed of 150rpm, the first-grade seed liquid of Bacillus subtilis KR2 (CGMCC No.3242) can be obtained by shaking and culturing for 48 hours. The culture is continued in the sterilized medium, and the secondary seed liquid of Bacillus subtilis KR2 (CGMCC No. 3242) can be obtained after 48 hours.

[0052] Inoculate the secondary seed liquid of Bacillus subtilis KR2 (CGMCC No.3242) into 35L sterilized liquid fermentation medium according to the inoculum size of 10%, (glucose: 30, yeast extract: 10, peptone: 10, chlorinated Sodium: 2, potassium dihydrogen phosph...

Embodiment 3

[0054] Example 3 Enzyme Activity Determination

[0055] In this example, the fermentation broth of Bacillus subtilis CGMCC NO.3242 was used to measure the enzyme activity. Definition of enzyme activity: at 25°C, the number of micrograms of nicotinamide produced after catalyzing the reaction of 1 mL of fermentation broth with 1 microgram of 3-cyanopyridine for 1 hour, the number of micrograms is the number of units of total enzyme activity. Niacinamide is detected by liquid chromatography, and the detection parameters are: chromatographic column: CLC-ODS column, 150mm × 6.0mm I.D; mobile phase: acetonitrile / water / sodium heptanesulfonate / triethylamine (50 / 450 / 0.8 g / 2mL) (pH3); flow rate: 1.2mL / min; column temperature: room temperature; detection wavelength: UV268nm. Under the conditions of the present invention, the biomass per milliliter of fermented liquid can reach up to 47mg wet bacteria, and the total enzyme activity can reach up to 1255U.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com