Battery capable of using light or electricity for charging

A storage battery and conductive glass technology, applied in the direction of secondary battery charging/discharging, battery electrodes, battery components, etc., can solve problems such as no successful precedents, achieve no carbon dioxide emissions, high social and economic benefits, and easy to miniaturize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

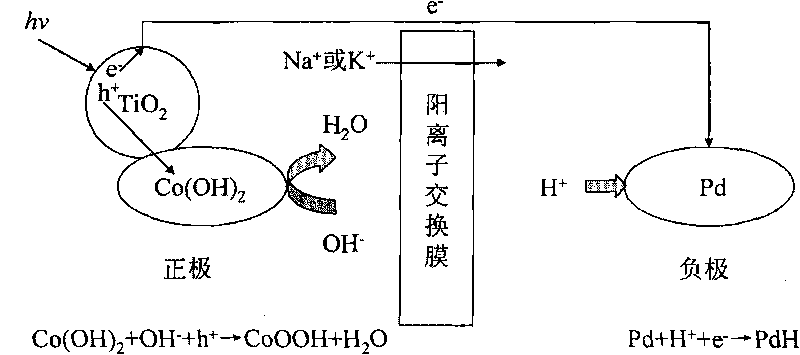

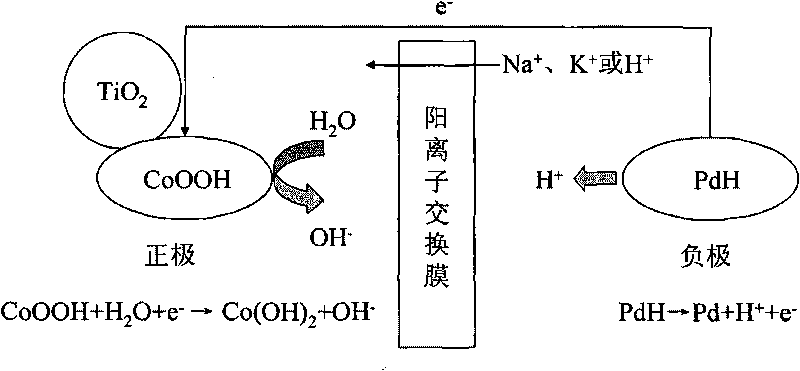

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Positive Electrode Fabrication

[0047] Get 0.1 g of anatase titanium dioxide powder (2 (2 、TiO 2 The mass ratio to PVA is 1:0.1:0.1. After drying, the nickel foam is coated with Co(OH) 2 and TiO 2 The face of the mixture is coated with TiO with indium tin oxide conductive quartz glass 2 Facing to each other, put it on the conductive glass, leaving 0.5cm margin on each side of the glass, at 0.1kgcm -2 Compression molding under high pressure. Under nitrogen protection, heat treatment at 500° C. for 10 minutes, and then cooling to prepare the positive electrode of the solar cell.

Embodiment 2

[0048] Example 2: Negative Electrode Fabrication

[0049] Get 1 gram of carbon-supported palladium (palladium content 5wt.%) and adhesive: polypropylene alcohol (PVA) aqueous solution (concentration: 5wt.%) for grinding and mixing, and apply it to a copper foam with an area of 1.5x1.5 square centimeters Above, the mass ratio of palladium on carbon to PVA is 1:0.1. After drying, at 100kgcm -2 Compression molding under high pressure. Under nitrogen protection, heat treatment at 500° C. for 15 minutes, and then cooling to prepare the negative electrode of the battery.

Embodiment 3

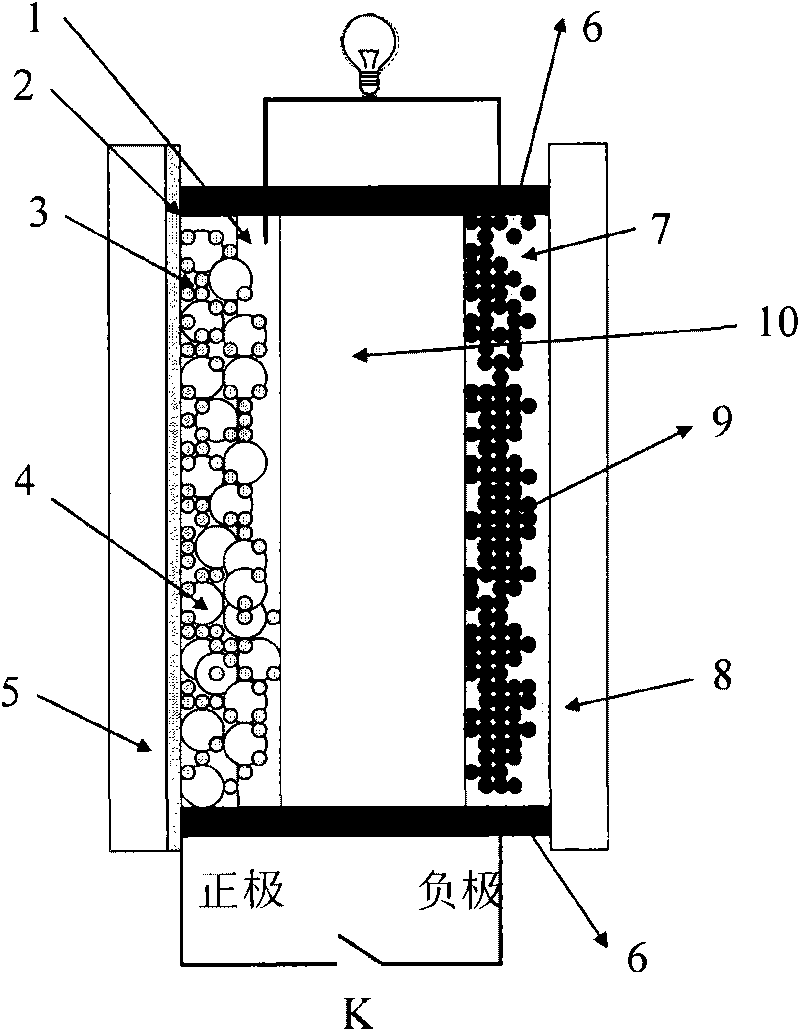

[0050] Example Three: Battery Assembly

[0051] Get 0.1 gram of anatase type titanium dioxide powder (2 Carry out grinding and mixing with anatase type titanium dioxide and polypropylene alcohol (PVA) aqueous solution (concentration is 5wt.%), be coated on the nickel foam that area is 1.5x1.5 square centimeters, Co(OH) 2 、TiO 2 The mass ratio to PVA is 1:0.2:0.2. After drying, the nickel foam is coated with Co(OH) 2 and TiO 2 The faces of the conductive quartz glass with indium tin oxide are coated with TiO 2 Facing to each other, put it on the conductive glass, leaving 0.5cm margin on each side of the glass, at 0.1kgcm -2 Compression molding under high pressure. Under nitrogen protection, heat treatment at 500° C. for 15 minutes, and then cooling to prepare the positive electrode of the battery.

[0052] TiO 2 The film side and the foamed nickel side are led out of the terminal, and the negative electrode obtained in Example 2 is led out of the terminal. The carbon-su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com